Adresse

304 Nord Kardinal

St. Dorchester Center, MA 02124

Arbeitszeiten

Montag bis Freitag: 7AM - 7PM

Am Wochenende: 10AM - 5PM

Adresse

304 Nord Kardinal

St. Dorchester Center, MA 02124

Arbeitszeiten

Montag bis Freitag: 7AM - 7PM

Am Wochenende: 10AM - 5PM

Quelle: Unsplash/Pixabay

Suchbegriffe: “12 volt fuses”, “automotive fuses”, “blade fuses”

Alt-Text: “12 volt DC fuses assortment showing blade-type, ANL, and glass tube fuses for automotive, marine, RV, and solar low-voltage electrical system overcurrent protection”

Abmessungen: 1200×630px Minimum

12 volt DC fuses serve as the primary overcurrent protection for billions of vehicles, boats, RVs, and off-grid solar systems worldwide. Unlike their AC counterparts or higher-voltage DC systems, 12V fuses must handle unique challenges: high current draw for the same power level, extreme temperature variations, and vibration in mobile applications.

This comprehensive guide covers 12V fuse types, amperage sizing methodology, voltage drop considerations, and application-specific selection criteria for automotive, marine, recreational vehicle, and solar battery systems.

The 12 volt standard emerged from automotive engineering in the 1950s and became ubiquitous due to:

Historical Context:

– Pre-1950s: 6V automotive systems (insufficient for modern loads)

– 1950s transition: 12V offered double the power without doubling wire size

– Current dominance: 12V powers most vehicles, boats, RVs globally

– Solar adoption: 12V battery banks common in small off-grid systems

Electrical Characteristics:

For the same power delivery, 12V systems require significantly higher current:

Power Comparison at 1200W:

- 120V AC: 1200W ÷ 120V = 10A

- 48V DC: 1200W ÷ 48V = 25A

- 24V DC: 1200W ÷ 24V = 50A

- 12V DC: 1200W ÷ 12V = 100A

Result: 12V fuse must handle 10× the current of 120V for same power!

Implications:

– Larger conductor sizes required (higher ampacity)

– Greater voltage drop per foot of wire

– Fuse heat generation: I²R losses significant at high current

– Connector and terminal stress (mechanical and thermal)

Most Common Type: Plastic body with two flat metal blades

Subcategories:

1. Standard ATO/ATC Fuses

– Abmessungen: 19mm × 5mm blade spacing

– Amperage Range: 1A to 40A

– Color Coding: Standardized (see table below)

– Anwendungen: Automotive interior circuits, RV accessory circuits

– Voltage Rating: 32V DC typical

– Kosten: $0.50-1.50 each

2. Mini Blade Fuses (ATM)

– Abmessungen: 11mm × 4mm blade spacing (smaller footprint)

– Amperage Range: 2A to 30A

– Anwendungen: Modern vehicles with space constraints

– Kosten: $0.75-2.00 each

3. Micro Blade Fuses

– Abmessungen: 9mm × 3.8mm blade spacing (smallest)

– Amperage Range: 5A to 30A

– Anwendungen: Late-model vehicles (2010+), compact fuse panels

– Kosten: $1.00-2.50 each

4. Maxi Blade Fuses

– Abmessungen: 29mm × 9mm blade spacing (largest)

– Amperage Range: 20A to 80A

– Anwendungen: High-current automotive circuits (alternator output, main feeds)

– Kosten: $2.00-4.00 each

Color Coding Standard (ATO/ATC):

| Amperage | Color | Typische Anwendung |

|---|---|---|

| 1A | Black | Instrument cluster |

| 2A | Grey | Sensitive electronics |

| 3A | Violet | Interior lights (LED) |

| 5A | Tan | Parking lights, radio memory |

| 7.5A | Brown | Fuel injection, computer |

| 10A | Red | Power windows, radio |

| 15A | Blue | Cigarette lighter, USB ports |

| 20A | Yellow | Cooling fans, power locks |

| 25A | Clear/Natural | Heater blower (low speed) |

| 30A | Green | Heater blower (high speed), power seats |

| 40A | Orange | Rear window defroster, large motors |

Vorteile:

– Easy visual inspection (blown fuse visible through plastic)

– Simple replacement (pull and push)

– Standardized across manufacturers

– Vibration-resistant (friction fit)

– Low cost and universal availability

Disadvantages:

– Limited to 40A maximum (standard), 80A (maxi)

– Plastic body can degrade in extreme heat (>80°C)

– Not waterproof (requires sealed fuse box)

Design: Blade-style with bolt-down terminals, no enclosure

Specifications:

– Amperage Range: 35A to 750A

– Physical Size: 1.5″ to 3″ length depending on rating

– Voltage Rating: 32V DC (12V/24V systems)

– Interrupt Rating: 5,000-10,000A typical

– Terminal-Typ: Bolt-down (5/16″ or M8 stud)

Common Sizes for 12V Systems:

– 40-60A: Small inverters (500W)

– 80-100A: Medium inverters (1000-1200W)

– 150-200A: Large inverters (1500-2400W)

– 300A+: Main battery disconnect, welding equipment

Anwendungen:

– Main battery disconnect protection

– Inverter input protection

– High-current solar charge controller circuits

– Windlass and bow thruster motor protection

– RV main house battery feed

Vorteile:

– Very high current capacity

– Replaceable without specialized tools

– Visual inspection possible

– Industry-standard sizing

– Lower cost than equivalent Class T fuses

Disadvantages:

– Exposed terminals (require protective cover or fuse holder)

– Larger physical size

– I²t rating not as precise as Class T fuses

– Limited to 750A maximum

Design: Fast-acting, current-limiting, cylindrical body

Specifications:

– Amperage Range: 1A to 1200A

– Voltage Rating: Up to 600V DC (suitable for high-voltage solar)

– Abmessungen: Various lengths (standardized per rating)

– Interrupt Rating: 200,000A (20kA) typical

– Reaktionszeit: Fast-acting (<0.01 seconds at 200% overload)Why Class T for Solar:

NEC Article 690.16 requires current-limiting overcurrent protection for certain PV systems:

Class T fuses provide:

1. Current limiting (reduces available fault current)

2. Ultra-fast response (protects semiconductors)

3. High interrupt rating (handles massive solar array short-circuit current)

4. Precise I²t rating (protects sensitive inverter electronics)

Common 12V Solar Ratings:

– 30-60A: Small solar charge controllers

– 100-150A: Battery main disconnect (12V systems <2000Ah)

- 200-300A: Large 12V inverters (2400-3600W)Vorteile:

– Highest interrupt rating (200kA)

– Current-limiting design (reduces damage during faults)

– Precise operation (±10% vs ±20% for blade fuses)

– UL listed for solar applications

Disadvantages:

– Higher cost ($15-60 each vs $2-5 for ANL)

– Requires specific Class T fuse holder

– Not as universally available

– Cannot visually inspect (opaque body)

Design: Glass cylinder with metal endcaps, internal element visible

Specifications:

– AGC (fast-blow): 1/4″ × 1-1/4″ length, 1-15A

– AGU (slow-blow): 1/4″ × 1-1/4″ length, 1-30A

– Voltage Rating: 32V DC

– Anwendungen: Older automotive, marine instrument panels, small electronics

Vorteile:

– Visual inspection (element visible through glass)

– Inexpensive ($0.50-1.00)

– Simple panel-mount holders

Disadvantages:

– Fragile (glass shatters from vibration)

– Low current capacity (<30A)

- No overload tolerance (blow at exactly rated current)

- Poor performance in vibration (vehicle/marine)

- Obsolete in most modern applicationsModern Replacement: Mini blade fuses have largely replaced glass tube fuses in vehicles manufactured after 2000.

Design: Bolt-down style similar to ANL but with plastic housing

Specifications:

– Amperage Range: 40A to 500A

– Voltage Rating: 32V DC or 58V DC (depending on model)

– Interrupt Rating: 10,000A typical

– Housing: Transparent plastic for visual inspection

Vorteile:

– Protected terminals (safer than exposed ANL)

– Visual inspection through transparent housing

– Corrosion-resistant (marine environments)

– Industry standardization (compatible with multiple manufacturers)

Disadvantages:

– Higher cost than ANL fuses

– Larger physical footprint (housing adds size)

– Limited to 500A maximum

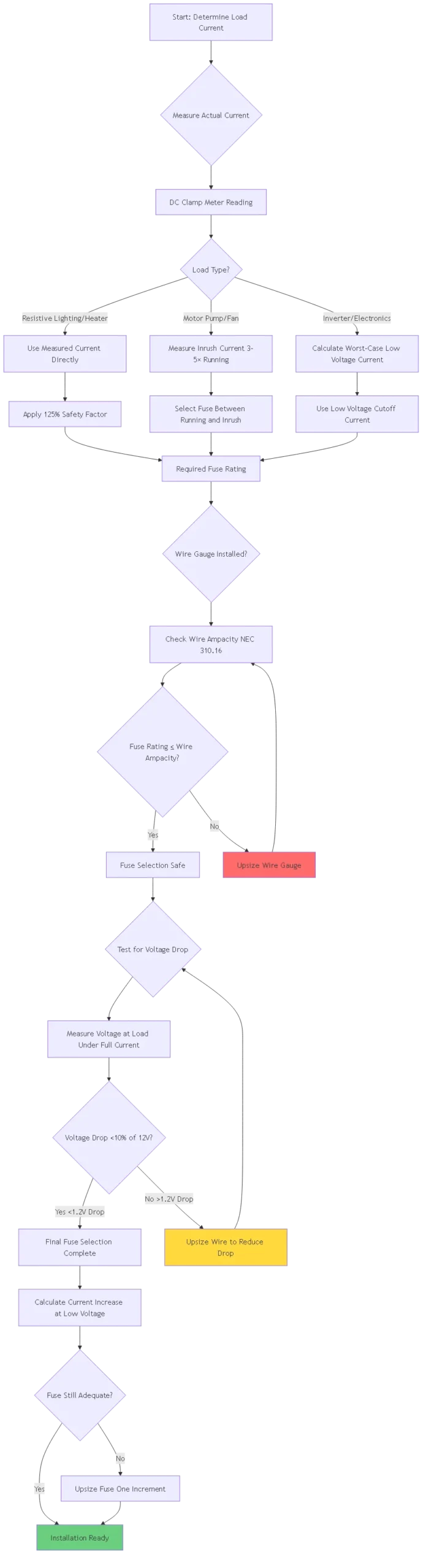

Fundamental Principle: Fuse rating must be 125% of maximum continuous current

Fuse Rating = Maximum Continuous Load Current × 1.25

Example 1: 12V LED Light Bar

Measured current: 12A continuous

Required fuse: 12A × 1.25 = 15A

Select: 15A blade fuse (exact match)

Example 2: 12V Water Pump

Measured current: 8A continuous

Required fuse: 8A × 1.25 = 10A

Select: 10A blade fuse

Why 125% Factor:

1. Ambient temperature affects fuse blow point

2. Voltage fluctuations increase current (P=VI constant)

3. Aging components draw more current

4. Surge currents during startup

5. Manufacturing tolerance in fuse ratings (±10-20%)

Motors present unique challenges due to startup inrush:

Typical Motor Inrush Characteristics:

Startup inrush: 3-5× running current

Duration: 0.5-2 seconds

Fuse must tolerate without blowing

Example: 12V Bilge Pump

Running current: 5A

Startup inrush: 5A × 4 = 20A for 1 second

Fuse Selection:

Wrong approach:

20A inrush → Use 20A × 1.25 = 25A fuse

Result: No protection for wire sized for 5A continuous!

Correct approach:

1. Size wire for running current: 5A × 1.25 = 6.25A → 10 AWG wire (30A capacity)

2. Select fuse rating between running and inrush:

- Too small (7.5A): Nuisance blowing on startup

- Too large (30A): Doesn't protect 10 AWG wire

- Optimal: 10A or 15A fuse (allows inrush, protects wire)

3. Test in actual application (cycle pump 10 times)

4. If nuisance blowing: Upsize fuse one increment

Slow-Blow vs Fast-Blow Fuses:

For motor loads, slow-blow (time-delay) fuses tolerate inrush:

Fast-blow fuse: Blows at 135% rated current in <1 second

slow-blow fuse: tolerates 200% current for 5-10 seconds

Motor Application:

- 20A inrush, 5A running, 10A fuse selected

- Fast-blow 10A: 20A surge = 200% → Blows immediately

- Slow-blow 10A: 20A surge = 200% → Tolerates for 5 seconds (pump started)

Select slow-blow for motors, fast-blow for electronics

Golden Rule: Fuse must protect the wire, not just the load

Wire Ampacity Reference (NEC Table 310.16):

| Wire Gauge | Strombelastbarkeit (75°C) | Maximum Fuse Rating |

|---|---|---|

| 18 AWG | 16A | 15A max |

| 16 AWG | 22A | 20A max |

| 14 AWG | 32A | 30A max |

| 12 AWG | 41A | 40A max |

| 10 AWG | 55A | 50A max |

| 8 AWG | 73A | 70A max |

| 6 AWG | 101A | 100A max |

| 4 AWG | 135A | 125A max |

| 2 AWG | 181A | 175A max |

Critical Safety Rule:

❌ DANGEROUS - Oversized Fuse:

Wire: 14 AWG (32A ampacity)

Fuse: 40A

Problem: Wire overheats before fuse blows → FIRE HAZARD

✓ SAFE - Properly Sized:

Wire: 14 AWG (32A ampacity)

Fuse: 30A maximum

Protection: Fuse blows before wire overheats

Voltage drop increases current draw for constant power loads:

Example: 12V Inverter, 1000W Output

At 13.0V: 1000W ÷ 13.0V = 77A input current

At 11.5V: 1000W ÷ 11.5V = 87A input current (13% higher!)

At 10.5V (depleted battery): 1000W ÷ 10.5V = 95A (23% higher!)

Fuse Sizing:

Wrong: 77A × 1.25 = 96A → Select 100A fuse

Correct: 95A (worst-case) × 1.25 = 119A → Select 125A fuse

Or: Use low-voltage disconnect to prevent operation below 11V

Voltage Drop Impact on Fuse Selection:

12V Light Circuit Example:

Wire: 14 AWG, 30 foot run

Load: 10A nominal at 12V

Voltage drop: 2V (significant for 12V system)

Voltage at load: 10V

Current increases to maintain power:

120W load at source

Actual current: 120W ÷ 10V = 12A at load (20% higher!)

Fuse sizing must account for voltage drop:

12A × 1.25 = 15A minimum fuse required (not 10A × 1.25 = 12.5A)

Factory OEM Circuits:

Modern vehicles use extensive fuse protection:

Typical Sedan Fuse Count:

- Passenger compartment fuse box: 30-50 fuses

- Engine compartment fuse box: 20-40 fuses

- Total: 50-90 individual fused circuits

Common Ratings:

- 5A: Instrument cluster, ECU memory

- 10A: Radio, interior lights

- 15A: Power outlet, horn

- 20A: Power windows, heated seats

- 30A: Blower motor, power locks

- 40-60A: Cooling fans, ABS pump (maxi fuses)

- 80-150A: Alternator output, main battery feed (mega/ANL fuses)

Aftermarket Accessory Installation:

Example 1: LED Light Bar (100W)

Current: 100W ÷ 12V = 8.3A

Fuse: 8.3A × 1.25 = 10.4A → Select 15A blade fuse

Wire: 16 AWG minimum (22A ampacity > 15A fuse)

Location: Tap into accessory circuit or add dedicated circuit

Example 2: Dash Camera (5W)

Current: 5W ÷ 12V = 0.4A

Fuse: 0.4A × 1.25 = 0.5A → Select 2A blade fuse

Wire: 20 AWG acceptable (11A ampacity >> 2A fuse)

Connection: Add-a-circuit fuse tap into existing circuit

Example 3: Winch (9500 lb, 4.5kW)

Current: 4500W ÷ 12V = 375A

Fuse: 375A × 1.25 = 469A → Select 500A ANL fuse

Wire: 4/0 AWG (230A ampacity) - INSUFFICIENT!

Parallel conductors: 2× 2/0 AWG (2 × 175A = 350A) - Still marginal

Correct: 2× 4/0 AWG (2 × 230A = 460A adequate)

Note: Winch duty cycle <10%, continuous rating not required

ABYC E-11 Standard Requirements:

American Boat & Yacht Council electrical standards mandate:

1. Overcurrent protection within 7 inches of power source

2. Marine-rated components (corrosion resistance)

3. Ignition protection in gasoline engine spaces

4. Proper wire ampacity per ABYC Table

Corrosion-Resistant Fuse Selection:

Environment Challenges:

- Salt spray (highly corrosive to terminals)

- High humidity (condensation inside fuse holders)

- Temperature extremes (engine room 60°C+)

- Vibration (wave action, engine)

Fuse Holder Requirements:

- Nickel-plated or gold-plated terminals

- Sealed covers (IP66/IP67 rated)

- Stainless steel mounting hardware

- UV-resistant materials

Recommended Fuse Types:

- ANL fuses in waterproof holders

- MEGA fuses (built-in corrosion resistance)

- Blade fuses in sealed Blue Sea Systems holders

Example: Saltwater Fishing Boat

Bilge Pump Circuit (Critical Safety)

Pump: 500 GPH, 12V, 5A running, 18A startup inrush

Fuse: 10A slow-blow ANL in waterproof holder

Wire: 14 AWG marine tinned copper

Installation: Below waterline = highest corrosion risk

Maintenance: Inspect terminals every 6 months, replace annually

Navigation Electronics Suite

Combined Load:

- GPS/Chartplotter: 2A

- VHF Radio: 6A transmit, 0.5A receive

- Fish finder: 1.5A

- AIS transponder: 2A

Total: 11.5A maximum simultaneous

Fuse: 11.5A × 1.25 = 14.4A → Select 15A blade fuse

Wire: 14 AWG marine-grade

Holder: Blue Sea Systems sealed blade fuse holder

Location: Protected helm area, above potential water intrusion

12V House Battery Distribution:

RVs typically separate "house" (living) from "chassis" (vehicle) 12V systems:

House Battery Typical Loads:

- Interior LED lights: 10-15A total

- Water pump: 8A

- Furnace blower: 15A

- Refrigerator (12V mode): 12A

- USB chargers: 5A

- Entertainment system: 8A

Total maximum: 63A

Main House Battery Fuse:

Worst-case simultaneous load: 63A

Fuse: 63A × 1.25 = 79A → Select 80A or 100A ANL fuse

Wire: 4 AWG (135A ampacity > 100A fuse)

Location: Within 7 inches of battery positive terminal (NEC 690.71)

Type: ANL in waterproof holder (outdoor installation common)

Individual Circuit Protection:

Water Pump:

- Running: 8A, Inrush: 24A (3×)

- Fuse: 15A slow-blow blade fuse

- Wire: 14 AWG

LED Lighting (all zones):

- Load: 12A continuous

- Fuse: 12A × 1.25 = 15A blade fuse

- Wire: 14 AWG

Refrigerator 12V Mode:

- Absorption cycle: 12A continuous

- Fuse: 12A × 1.25 = 15A blade fuse

- Wire: 14 AWG

12V System Example: Small Cabin

System Components:

Battery: 400Ah LiFePO4 at 12.8V

Solar Array: 800W (optimal conditions)

Charge Controller: 60A MPPT

Inverter: 2000W (12V input)

Fuse Locations and Sizing:

1. Solar Array to Charge Controller

Array Short-Circuit Current: 15A per panel × 2 panels = 30A

Fuse: 30A × 1.25 = 37.5A → Select 40A Class T fuse

Wire: 10 AWG (55A ampacity)

Holder: Inline waterproof fuse holder (outdoor rated)

2. Charge Controller to Battery

Controller Output: 60A maximum

Fuse: 60A × 1.25 = 75A → Select 80A ANL fuse

Wire: 6 AWG (101A ampacity)

Location: Within 7 inches of battery positive (NEC 690.71)

Type: ANL in waterproof holder or Class T

3. Battery to Inverter

Inverter Input at Low Voltage:

2000W ÷ 10.5V (depleted battery) = 190A

Fuse: 190A × 1.25 = 238A → Select 250A Class T or 300A ANL

Wire: Parallel 2/0 AWG (2 × 175A = 350A capacity)

Location: Battery positive terminal

Type: Class T preferred (current-limiting for inverter protection)

4. DC Load Circuits (Lighting, Pumps)

Combined DC loads: 15A maximum

Fuse: 15A × 1.25 = 19A → Select 20A blade fuse

Wire: 12 AWG

Panel: Blue Sea Systems blade fuse panel

Inline Blade Fuse Holders:

Use Case: Aftermarket additions, single-circuit protection

Types:

- Open blade holder: Indoor use only ($2-5)

- Waterproof sealed: Outdoor/marine ($8-15)

- ATC add-a-circuit: Tap existing fuse box ($5-10)

Wire Connection:

- Ring terminals recommended (crimped)

- Solder and heat shrink for vibration resistance

- 12-14 AWG wire capacity typical

ANL Fuse Holders:

Types:

- Inline single: Most common ($15-30)

- Panel-mount: Multiple fuses in one enclosure ($40-80)

- Waterproof covers: Marine/outdoor required ($25-50)

Installation:

- Bolt terminals: Torque 100-150 in-lbs

- Use star washers (prevent loosening from vibration)

- Apply anti-oxidant compound (Noalox) on copper terminals

- Marine: Use tinned copper lugs and stainless hardware

Class T Fuse Holders:

Requirements:

- UL listed Class T holder (specific to fuse type)

- Proper voltage rating (match system voltage)

- Adequate interrupt rating (>20kA)

Cost: $40-100 for holder + $20-60 per fuse

Brands: Littelfuse, Mersen, Bussmann

Installation: Professional recommended (solar NEC compliance)

NEC and ABYC Requirements:

Both standards mandate overcurrent protection close to power source:

NEC 690.71 (Solar Systems):

"Overcurrent protection shall be provided within 7 inches (178mm)

of battery positive terminal"

ABYC E-11.17.2 (Marine):

"Overcurrent protection as close as practicable to source,

not exceeding 7 inches"

Reason: Unprotected wire is fire hazard if short-circuited

Installation Procedure:

1. Identify battery positive terminal

2. Measure 7 inches maximum from terminal

3. Install fuse holder within this distance

4. Route protected wire to loads

5. Use minimum wire length (reduces risk)

6. Support wire every 18 inches (prevent chafing)

Crimp Terminals (Preferred for 12V):

Advantages:

- Vibration resistant (no cold joints like solder)

- Gas-tight connection (prevents corrosion)

- Faster installation

- Stronger mechanical connection

Procedure:

1. Strip wire insulation 3/8" - 1/2"

2. Insert into crimp terminal

3. Use ratcheting crimper (not pliers!)

4. Crimp in barrel, not insulation area

5. Tug test: Pull with 20-30 lbs force

6. Apply heat shrink tubing over crimp

Terminal Types:

Ring Terminals: Best for bolted connections (fuse holders, busbars)

- Use correct wire gauge size

- Match bolt size (1/4", 5/16", 3/8")

Spade Terminals: Quick-connect applications

- Not recommended for high-vibration

- Use locking spade terminals for critical circuits

Butt Connectors: Wire-to-wire splicing

- Heat-shrink type preferred (waterproof seal)

- Crimp both sides

Problem 1: Fuse Blows Immediately Upon Insertion

Cause: Short circuit in wiring or equipment

Diagnostic Steps:

1. Disconnect load completely from circuit

2. Measure resistance positive to negative/ground

3. Should be >1kΩ (infinite for most circuits)

4. If <1Ω: Short circuit present

Locate short:

1. Visual inspection: Look for damaged insulation, pinched wires

2. Divide-and-conquer: Disconnect loads one by one

3. When resistance returns to >1kΩ, last disconnected component is fault

4. Repair damaged wire or replace faulty component

Problem 2: Fuse Blows Under Normal Load

Possible Causes:

1. Undersized fuse for actual load

2. Voltage drop causing higher current draw

3. Aging equipment drawing more current

4. Poor connections creating heat

5. Wrong fuse type (fast-blow instead of slow-blow for motor)

Diagnosis:

1. Measure actual current with DC clamp meter

2. Compare to fuse rating

3. If current > fuse rating: Load problem or undersized fuse

4. If current < fuse rating: Fuse defective or poor connection causing heat

Check voltage drop:

- Measure voltage at battery: 12.6V

- Measure voltage at load: Should be >11.5V

- If <11V: run

Problem 3: Corrosion in Fuse Holder (Marine)

Symptoms:

- Green/white powder on terminals

- High resistance (voltage drop across holder)

- Intermittent connection

- Heat generation

Cleaning Procedure:

1. Disconnect power completely

2. Remove fuse

3. Clean terminals:

- Wire brush or ScotchBrite pad

- Contact cleaner spray (CRC QD Electronic Cleaner)

- Dry completely

4. Apply protective coating:

- DeoxIT Gold for gold-plated contacts

- Boeshield T-9 or Corrosion-X for general marine

5. Reassemble with fresh fuse

6. Test voltage drop: <0.1V acceptable across holder

Prevention:

- Use waterproof sealed fuse holders (IP67 rated)

- Apply dielectric grease to terminals

- Inspect quarterly in marine environments

- Replace holders every 5 years in saltwater applications

1. Can I use automotive blade fuses for marine applications?

Yes, but only in waterproof sealed fuse holders rated IP66/IP67. Standard automotive blade fuses are suitable for marine use if protected from moisture and salt spray. However, the fuse holder must be marine-rated with corrosion-resistant terminals (nickel or gold-plated), sealed cover, and stainless steel mounting hardware. For critical safety circuits (bilge pumps, navigation lights), use ANL or MEGA fuses in dedicated marine-grade holders. Inspect terminals quarterly and apply dielectric grease to prevent corrosion.

2. What's the difference between fast-blow and slow-blow fuses?

Fast-blow fuses interrupt current in <1 second at 135% rating, protecting sensitive electronics from even brief overloads. Slow-blow (time-delay) fuses tolerate 200% current for 5-10 seconds, allowing motor startup inrush without nuisance blowing. Use fast-blow for electronics, LED lights, and circuits without motors. Use slow-blow for motors (pumps, fans, winches), inverters, and any load with high startup surge. Externally identical blade fuses can be fast or slow-blow—check packaging carefully.

3. How do I size a fuse for a 12V inverter?

Calculate worst-case input current at lowest battery voltage: Inverter Power (W) ÷ Lowest Voltage (V) = Current (A), then multiply by 1.25. Example: 1500W inverter with 10.5V low-voltage cutoff: 1500W ÷ 10.5V = 143A, × 1.25 = 179A minimum fuse. Select 200A or 250A ANL/Class T fuse. Wire must be sized for fuse rating: 200A requires 4/0 AWG minimum. Never size fuse based on nominal 12V—battery voltage sags under load.

4. Can I replace a blown fuse with a higher amperage rating?

Only if the wire ampacity supports the higher fuse rating. Fuses protect wires from overheating—using a 30A fuse on 18 AWG wire (16A ampacity) creates fire hazard. If fuses blow repeatedly at correct rating: (1) Measure actual load current (may exceed expectations), (2) Check for short circuits, (3) Upgrade wire gauge first, then fuse. Never exceed wire ampacity with fuse rating. Repeated fuse blowing indicates electrical problem requiring diagnosis, not bandaid fix with larger fuse.

5. Why does my marine fuse corrode so quickly?

Saltwater environments are extremely corrosive due to salt spray and humidity. Standard fuse holders allow moisture entry, causing galvanic corrosion between dissimilar metals. Solutions: (1) Use waterproof sealed holders (Blue Sea Systems, Ancor), (2) Apply dielectric grease to all connections, (3) Use tinned copper wire and gold-plated terminals, (4) Install in protected location away from spray, (5) Inspect and clean quarterly, (6) Replace holders every 3-5 years. ANL and MEGA fuses in quality waterproof holders last 10× longer than blade fuses in standard holders.

6. What size fuse do I need for a 12V winch?

Size for worst-case stalled load, not rated load. A 9500 lb winch draws 350-450A when stalled under heavy load. Fuse sizing: 450A × 1.25 = 563A → Select 600A or 750A ANL fuse. However, winch duty cycle is <10% (short pulls), so continuous wire rating less critical. Use 2× 2/0 AWG or 2× 4/0 AWG parallel. Many winch kits include appropriately sized fuse. Never use fuse <500A for 9500 lb winch—will blow during hard pulls.

7. How do I identify if a fuse is blown without removing it?

Blade fuses: Look through transparent plastic body—metal element should be continuous. If broken/melted, fuse is blown. Glass tube fuses: Element visible through glass—look for break or discoloration. ANL fuses: Element visible—check for melted section or complete separation. Testing: Use multimeter in resistance mode across fuse terminals with power OFF. Good fuse reads <0.1Ω; blown fuse reads infinite (OL). Visual inspection most reliable for blade/glass, meter test needed for ANL/Class T fuses.

12 volt DC fuses provide essential protection for automotive, marine, RV, and solar electrical systems. Proper fuse type selection, amperage sizing, and installation techniques ensure safe, reliable operation in mobile and off-grid applications.

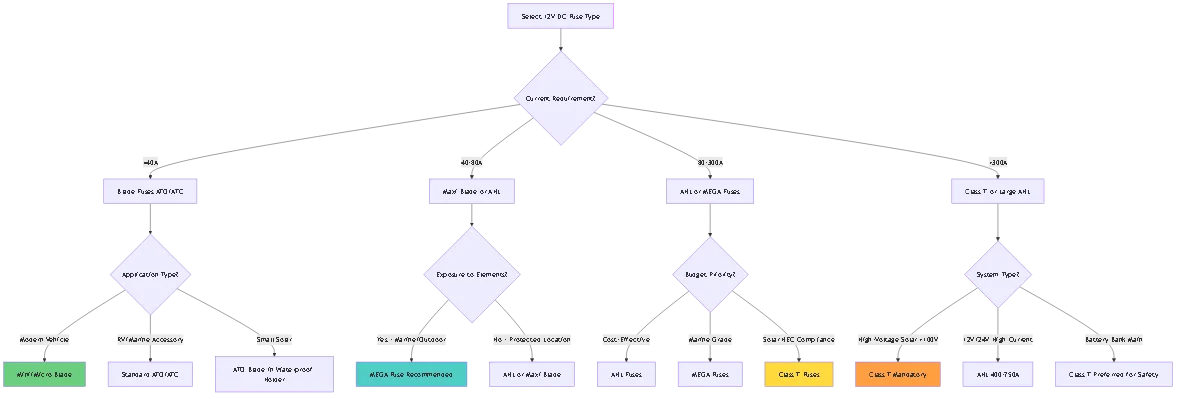

Selection Summary:

By Current Range:

- <40A: Blade fuses (ATO/ATC/Mini/Micro) - universal, inexpensive

- 40-80A: Maxi blade or ANL fuses - most cost-effective

- 80-300A: ANL or MEGA fuses - industrial-grade protection

- >300A: Class T fuses - current-limiting, solar-compliant

By Application:

- Automotive accessories: Blade fuses in add-a-circuit taps

- Marine equipment: MEGA fuses in waterproof holders, corrosion-resistant

- RV house battery: ANL main disconnect + blade fuse panel for circuits

- Solar systems: Class T for NEC compliance, ANL for budget builds

Installation Checklist:

- [ ] Fuse rating = Load current × 1.25 (minimum)

- [ ] Fuse rating ≤ Wire ampacity (critical safety)

- [ ] Slow-blow for motors, fast-blow for electronics

- [ ] Waterproof holder for outdoor/marine

- [ ] Install within 7 inches of battery positive

- [ ] Crimp terminals with heat shrink

- [ ] Test: Voltage drop <0.1V across fuse/holder

- [ ] Label fuse rating and protected circuitMaintenance Reminders:

- Inspect blade fuses annually (visible element check)

- Inspect marine fuses quarterly (corrosion prevention)

- Clean corroded terminals immediately

- Replace fuse holders every 5-10 years

- Keep spare fuses onboard (2× each rating)

- Verify fuse ratings match circuit labels

When to Upgrade:

- Blade to ANL: >40A circuits, high vibration

- ANL to Class T: Solar NEC compliance, current-limiting needed

- Standard to waterproof holders: Marine, outdoor, RV exterior

- Glass tube to blade: Any modern vehicle/boat (better reliability)

Proper 12V fuse selection and installation protects equipment, prevents fires, and ensures years of trouble-free operation in demanding mobile and off-grid environments.

Schwerpunkt Stichwort: 12 volt dc fuses

URL Slug: 12-volt-dc-fuses

Meta-Titel: 12 Volt DC Fuses Guide: Types, Sizing & Selection for Automotive/Marine

Meta-Beschreibung: Complete guide to 12V DC fuses for automotive, marine, RV, and solar applications. Learn fuse types, amperage sizing, voltage ratings, and proper installation methods for low-voltage protection.

Inhaltliche Ebene: Tier 3 (Supporting Content)

Umstellungstrichter: Top of Funnel (Bekanntheit)

Ziel-Wortzahl: 2800-4000 Wörter

Ziel Meerjungfrauen-Diagramme: 3

Bitte konfigurieren Sie diese in den Rank-Math-Einstellungen und löschen Sie dann dieses Feld vor der Veröffentlichung.

Yes, but only in waterproof sealed fuse holders rated IP66/IP67. Standard automotive blade fuses are suitable for marine use if protected from moisture and salt spray. The fuse holder must be marine-rated with corrosion-resistant terminals, sealed cover, and stainless steel mounting hardware. Inspect terminals quarterly and apply dielectric grease.

Fast-blow fuses interrupt current in less than 1 second at 135% rating, protecting sensitive electronics. Slow-blow (time-delay) fuses tolerate 200% current for 5-10 seconds, allowing motor startup inrush. Use fast-blow for electronics and LED lights. Use slow-blow for motors, pumps, fans, and inverters with high startup surge.

Calculate worst-case input current at lowest battery voltage: Inverter Power (W) ÷ Lowest Voltage (V) = Current (A), then multiply by 1.25. Example: 1500W inverter with 10.5V cutoff: 1500W ÷ 10.5V = 143A, × 1.25 = 179A minimum. Select 200A or 250A ANL/Class T fuse. Never size based on nominal 12V—battery voltage sags under load.

Only if the wire ampacity supports the higher fuse rating. Fuses protect wires from overheating—using oversized fuses creates fire hazard. If fuses blow repeatedly: measure actual load current, check for short circuits, upgrade wire gauge first, then fuse. Never exceed wire ampacity with fuse rating.

Saltwater environments cause rapid corrosion from salt spray and humidity. Solutions: use waterproof sealed holders, apply dielectric grease, use tinned copper wire and gold-plated terminals, install in protected locations, inspect quarterly, and replace holders every 3-5 years. ANL and MEGA fuses in waterproof holders last significantly longer.

Size for worst-case stalled load. A 9500 lb winch draws 350-450A when stalled. Fuse sizing: 450A × 1.25 = 563A → Select 600A or 750A ANL fuse. Use 2× 2/0 AWG or 2× 4/0 AWG parallel wiring. Never use fuse below 500A for 9500 lb winch—will blow during hard pulls.

Blade fuses: Look through transparent plastic body—metal element should be continuous. Glass tube fuses: Element visible through glass—look for break or discoloration. Testing: Use multimeter in resistance mode across fuse terminals with power OFF. Good fuse reads less than 0.1Ω; blown fuse reads infinite.