Adresse

304 Nord Kardinal

St. Dorchester Center, MA 02124

Arbeitszeiten

Montag bis Freitag: 7AM - 7PM

Am Wochenende: 10AM - 5PM

Adresse

304 Nord Kardinal

St. Dorchester Center, MA 02124

Arbeitszeiten

Montag bis Freitag: 7AM - 7PM

Am Wochenende: 10AM - 5PM

Selecting the best solar fuse requires balancing quality, cost, availability, and application-specific requirements. Not all gPV-rated fuses perform identically—differences in arc-quenching filler quality, ceramic body construction, end cap materials, and manufacturer testing rigor directly impact reliability, lifespan, and safety under real-world rooftop conditions.

This selection-focused guide provides practical decision tools for choosing optimal solar fuses. We compare leading brands (Mersen, Littelfuse, Eaton Bussmann, SIBA, Ferraz Shawmut), identify quality indicators distinguishing premium from budget fuses, analyze price-performance trade-offs, and present decision matrices for residential, commercial, and utility-scale applications.

For procurement managers, system designers, and installers making buying decisions for projects from single-home installations to multi-MW solar farms, this guide cuts through marketing claims to deliver actionable selection criteria based on technical merit, total cost of ownership, and field-proven performance.

💡 Selection Priority: “Best” depends on application. Residential rooftop: prioritize cost and local availability. Commercial/utility: prioritize reliability and manufacturer support. Critical systems: prioritize premium brands with extensive testing data and low failure rates.

Mersen (France):

Strengths:

– Pioneers of gPV rating (involved in IEC 60269-6 development)

– Extensive DC arc testing facilities

– Superior silica sand quality (99.8% purity, calibrated grain size)

– Wide product range: 1-1250A, up to 1500V DC

– Excellent technical documentation and application support

Popular Series:

– FR22GG69V: 22×58mm, 10-160A, 1500V DC, gPV rated

– FR10GG69V: 10×38mm, 1-32A, 1000V DC, gPV rated

– PV-10×38: Economy line for residential, 1-25A

Price Range: $12-45 per fuse (premium positioning)

Availability: Global distribution, 2-4 week lead times for specialty ratings

Am besten für: Utility-scale projects, high-reliability requirements, European markets

Littelfuse (USA):

Strengths:

– Largest production volume (economies of scale = competitive pricing)

– Strong UL 2579 certification compliance (North American preference)

– Automotive-derived quality processes (extensive automated testing)

– Good stock availability through electrical distributors

Popular Series:

– KLKD Series: 10×38mm, 1-30A, 600-1000V DC, fast-acting

– KLDR Series: 14×51mm, 2-63A, 1000-1500V DC, time-delay available

– PV Series: Specifically marketed for solar, 1-32A

Price Range: $8-30 per fuse (mid-range, volume discounts available)

Availability: Excellent (2-3 day ship from US stock for common ratings)

Am besten für: North American residential/commercial, cost-sensitive projects, rapid delivery needs

Eaton Bussmann (USA):

Strengths:

– Long history in electrical protection (125+ years)

– Robust mechanical construction (thick ceramic, heavy-duty end caps)

– Good breaking capacity specifications (65-100 kA typical vs 50 kA minimum)

– Integration with Eaton breaker/disconnect product line

Popular Series:

– FWP Series: Cylindrical, 1-30A, 600V DC

– FWH Series: Midget, 1-60A, 1000V DC

– PV Series: gPV rated, 10×38 and 14×51 sizes

Price Range: $10-35 per fuse

Availability: Good through Eaton distributors, 3-7 day lead times

Am besten für: Projects using Eaton equipment ecosystem, seeking heavy-duty construction

SIBA (Germany):

Strengths:

– Specialized in high-voltage DC fuses (up to 1500V DC)

– Compact designs (space-efficient for dense combiner boxes)

– Good European availability

Price Range: $9-32 per fuse

Am besten für: European projects, space-constrained applications

Ferraz Shawmut (USA/France):

Strengths:

– Now part of Mersen group (shares some technology)

– Strong in industrial applications

– Good technical support

Price Range: $11-38 per fuse

Am besten für: Industrial solar installations, retrofit projects

DF Electric (China):

Strengths:

– Aggressive pricing ($3-12 per fuse, 50-70% below Tier 1)

– IEC 60269-6 certified (meets minimum standards)

– Improving quality trajectory

Weaknesses:

– Limited long-term field data

– Quality consistency concerns (batch-to-batch variation)

– Sparse technical documentation

Am besten für: Budget-constrained projects, short-term applications, risk-tolerant buyers

Ceramic Body Quality:

| Quality Level | Body Material | Indicators |

|---|---|---|

| Premium | High-grade steatite or alumina ceramic | Uniform color, smooth surface, no pores, 3-4mm wall thickness |

| Standard | Standard porcelain | Slightly rough surface, 2-3mm walls, minor color variation OK |

| Budget | Low-grade ceramic | Visible pores, uneven color, <2mm walls, brittle feel |

Test: Gently tap fuse on hard surface—premium ceramic produces clear “ring”, budget ceramic produces dull “thunk”.

End Cap Construction:

Premium:

– Heavy copper or brass (50-100g weight for 14×51mm fuse)

– Silver or tin plating for corrosion resistance

– Precisely machined contact surfaces (smooth, no burrs)

– Indicator pin mechanism (striker pin) integrated

Budget:

– Thin stamped metal (20-40g weight)

– No plating or basic zinc coating

– Rough contact surfaces

– No indicator feature

Silica Sand Quality (Non-Visible):

Premium fuses use calibrated sand:

– Grain size: 150-250 μm (uniform)

– Purity: >99.5% SiO₂

– Moisture: <0.1%

- Result: Consistent arc extinction, no gas pockets

Budget fuses may use:

– Mixed grain sizes (50-500 μm)

– Lower purity (95-98% SiO₂, contaminants)

– Higher moisture (condensation risk)

– Result: Unpredictable arc behavior, potential fuse failure

How to Verify: Request test reports showing breaking capacity at rated DC voltage. Premium fuses consistently interrupt at prospective current; budget fuses may show failures in test series.

IEC 60269-6 Certification Levels:

Full Type Testing (Premium):

– Complete test series per standard (100+ individual tests)

– Testing at multiple voltages: 1000V, 1500V DC

– Multiple current levels: 1×, 1.25×, 1.45×, 3×, 5×, 10× rated

– Temperature testing: -40°C to +85°C

– Breaking capacity: 50 kA minimum, often tested to 100 kA

– Endurance testing: 1000+ make/break cycles at rated current

Certificate: Issued by KEMA, TÜV, UL, or equivalent lab

Routine Testing (Standard):

– Sample testing (5-10% of production)

– Single voltage verification

– Breaking capacity at nominal conditions only

– Temperature testing at 25°C and 70°C only

Certificate: Manufacturer self-declaration with occasional audit

Minimal Compliance (Budget):

– Baseline testing for certification only

– No ongoing quality verification

– May not test at full 1500V DC (expensive test equipment)

Certificate: Valid but minimal data behind it

How to Verify: Request full test report, not just certificate. Premium manufacturers provide 20-50 page reports with graphs and detailed data. Budget brands provide 2-3 page summary or no report.

Premium (Mersen, Littelfuse, Eaton):

– Detailed datasheets: time-current curves, I²t data, derating factors

– Application notes: sizing calculators, coordination studies

– Technical support: Phone/email engineer access

– Samples: Available for qualification testing

– Warranty: 2-5 years, replacement guarantee

Budget (Generic brands):

– Basic datasheets: nominal ratings only, generic curves

– No application support

– Technical support: Sales rep (not engineer)

– Samples: May require minimum order

– Warranty: 90 days to 1 year, may not honor

Value of Support: For 100 kW system using 50 fuses, $500 in premium fuse cost buys access to engineering support worth $2000-5000 in consulting value.

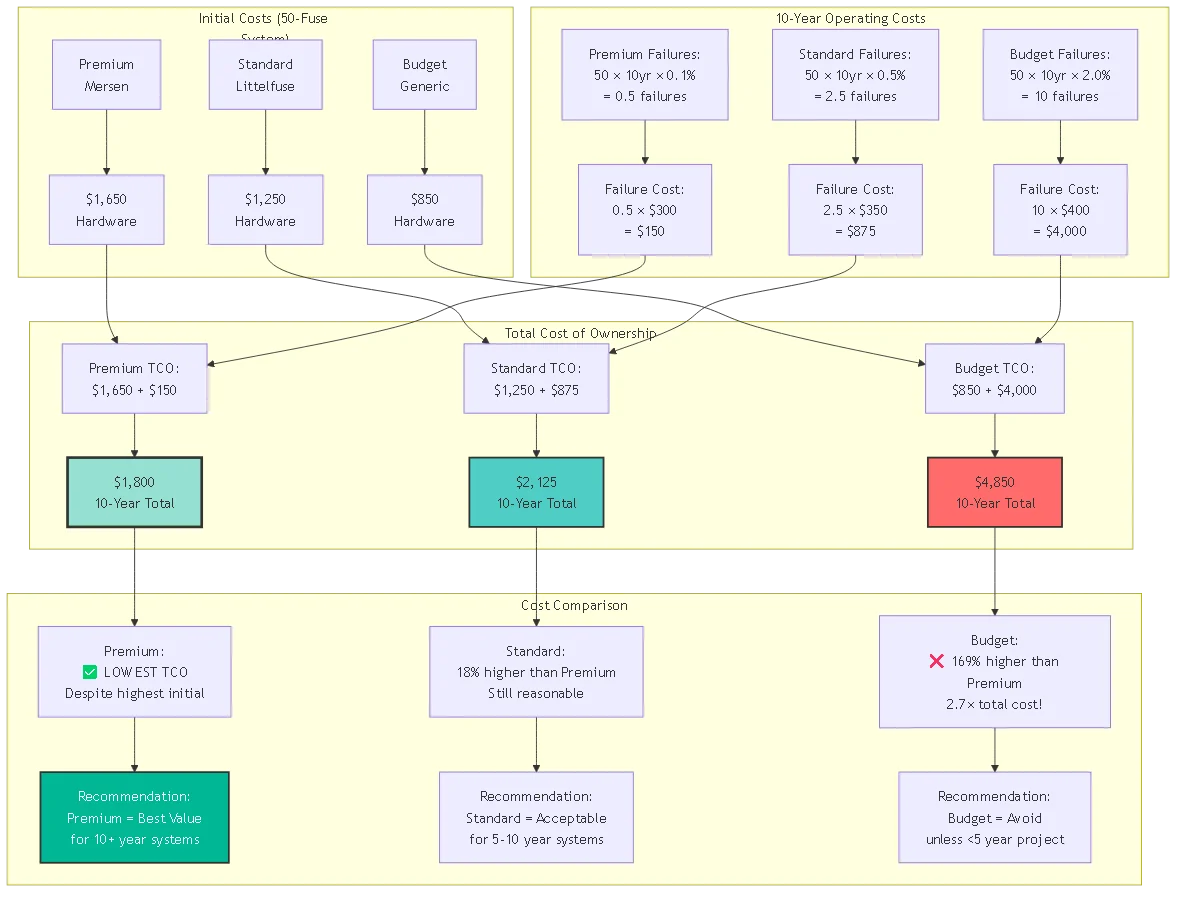

50-String Residential/Commercial System Example:

| Brand/Tier | Fuse Cost Each | 50 Fuses Total | Fuse Holders | Total Hardware |

|---|---|---|---|---|

| Mersen (Premium) | $18 | $900 | $750 | $1,650 |

| Littelfuse (Standard) | $12 | $600 | $650 | $1,250 |

| Eaton Bussmann (Standard) | $14 | $700 | $700 | $1,400 |

| DF Electric (Budget) | $6 | $300 | $550 | $850 |

Initial Cost Difference: Mersen vs Budget = $800 premium (94% more expensive) for 50-fuse system

Assumed Failure Rates (based on industry data):

– Premium: 0.1% per year (1 failure per 1000 fuse-years)

– Standard: 0.5% per year (1 failure per 200 fuse-years)

– Budget: 2.0% per year (1 failure per 50 fuse-years)

Cost Per Failure Event:

– Replacement fuse: $6-18 (tier-dependent)

– Labor (truck roll, diagnostics, replacement): $200-500

– Production loss during fault (1-2 days): $50-200 (system size dependent)

– Total per failure: $250-700

10-Year TCO Calculation (50-fuse system):

Prämie (Mersen):

– Initial: $1,650

– Expected failures: 50 fuses × 10 years × 0.1% = 0.5 failures

– Failure cost: 0.5 × $300 = $150

– 10-Year TCO: $1,800

Standard (Littelfuse):

– Initial: $1,250

– Expected failures: 50 × 10 × 0.5% = 2.5 failures

– Failure cost: 2.5 × $350 = $875

– 10-Year TCO: $2,125

Budget (DF Electric):

– Initial: $850

– Expected failures: 50 × 10 × 2.0% = 10 failures

– Failure cost: 10 × $400 = $4,000

– 10-Year TCO: $4,850

Ergebnis: Premium fuses have LOWEST total cost of ownership despite highest initial price. Budget fuses cost 2.7× more over 10 years due to failures.

When Does Premium Pay Off?

Comparing Premium vs Standard:

– Premium additional cost: $400

– Failure prevention: 2 failures over 10 years

– Savings per prevented failure: $350

– Break-even: After 1.1 failures prevented (≈5 years)

Comparing Standard vs Budget:

– Standard additional cost: $400

– Failure prevention: 7.5 failures over 10 years

– Savings: $2,625

– Break-even: After 1.5 failures prevented (≈2 years)

Schlussfolgerung: For systems with >5 year expected life, premium or standard fuses always more cost-effective than budget options.

Optimal Choice: Littelfuse Standard or Eaton Bussmann

Rationale:

– System size: 10-50 fuses typically

– Initial cost sensitivity: Moderate

– Service access: Usually easy (homeowner-accessible disconnect)

– Failure impact: Low (single-string outage = 2-5% capacity loss)

– Standard tier provides excellent balance

Specific Product Recommendations:

– Littelfuse KLKD010: 10×38mm, 10-25A, 1000V DC, $10-15 each

– Eaton Bussmann PV-10M: 10×38mm midget, 1-30A, 600V DC, $12-18 each

Quantity Discounts:

– 10-24 pieces: List price

– 25-99 pieces: 15% discount

– 100+ pieces: 25-30% discount (relevant for large residential developments)

Avoid: Budget brands for residential—failure requires homeowner service call ($300-500), wiping out $5-10 savings per fuse.

Optimal Choice: Mersen or Littelfuse Premium Series

Rationale:

– System size: 50-500 fuses

– Service access: Often rooftop, requires skilled technician

– Failure impact: Moderate (production loss $100-500/day)

– Reliability critical for commercial ROI

Specific Product Recommendations:

– Mersen FR10GG69V: 10×38mm, 1-32A, 1000V DC, $14-20

– Mersen FR14GG69V: 14×51mm, 2-63A, 1500V DC, $18-28

– Littelfuse KLDR Series: 14×51mm with time-delay options

Additional Considerations:

– Match fuse brand to circuit breaker brand if possible (Eaton fuses with Eaton breakers) for single-vendor support

– Specify indicator pins (+$2-3 each) for large systems (visual troubleshooting saves hours)

– Order 10-20% spares initially (overnight shipping expensive for unplanned failures)

Optimal Choice: Mersen Premium Only

Rationale:

– System size: 500-50,000+ fuses

– Service contracts: $10,000-500,000 annually

– Failure impact: High ($1,000-10,000/day production loss)

– Procurement: Formal RFQ process with qualification testing

Specific Product Recommendations:

– Mersen FR14GG69V: Most common for string protection

– Mersen FR22GG69V: For combiner-level protection

Procurement Strategy:

– Request samples for qualification (test 10-20 fuses before committing to 10,000+ order)

– Negotiate volume pricing: 10,000+ pieces can achieve 40-50% off list

– Establish consigned inventory agreement (manufacturer stocks spares at project site)

– Include fuse replacement in O&M contractor scope (use standardized brand across all projects)

Quality Verification:

– Require batch testing: Every production lot tested for breaking capacity

– Traceability: Lot codes marked on fuses for failure analysis

– Manufacturer site audit: For orders >$100,000, audit production facility

Typical Discount Tiers (from list price):

| Quantity | Residential/Small | Kommerziell | Maßstab für Versorgungsunternehmen |

|---|---|---|---|

| 1-9 pieces | List price | List -5% | N/A (minimum 100) |

| 10-24 | -10% | -15% | N/A |

| 25-99 | -15% | -20% | -25% |

| 100-499 | -20% | -25% | -30% |

| 500-999 | -25% | -30% | -35% |

| 1000-4999 | -30% | -35% | -40% |

| 5000+ | -35% | -40% | -45-50% (negotiable) |

Example Savings:

– 1000-piece order (utility project)

– List price: $18 each = $18,000 total

– With 40% discount: $10,800

– Savings: $7,200 (40% reduction)

Approach 1 – Standardization Discount:

If managing multiple projects, standardize on one brand across all:

– Negotiate annual contract: “We’ll buy 5,000 fuses this year across 10 projects, all Littelfuse”

– Manufacturer offers: 35-40% discount + priority technical support

– Additional value: Simplified inventory, spare parts interchangeable across projects

Approach 2 – Consignment Agreement:

For large projects (>1000 fuses):

– Manufacturer stocks spares at project site (100-200 pieces)

– Pay only when consumed

– Benefit: Zero inventory carrying cost, immediate availability

Approach 3 – Direct Manufacturer Purchasing:

For orders >$50,000:

– Bypass distributor, buy directly from Mersen/Littelfuse

– Additional 10-15% savings

– Trade-off: Longer lead times (4-8 weeks vs 3-7 days distributor), minimum quantities

Standard Manufacturer Warranties:

Premium (Mersen, Littelfuse):

– Duration: 2-5 years from manufacture date

– Coverage: Defects in materials and workmanship

– Remedy: Free replacement fuse + shipping

– Failure analysis: Provided for failed fuses (helps diagnose system issues)

Standard (Eaton, SIBA):

– Duration: 1-2 years

– Coverage: Material defects only

– Remedy: Replacement fuse (customer pays shipping)

Budget (Generic brands):

– Duration: 90 days to 1 year

– Coverage: DOA only (dead on arrival)

– Remedy: May require return shipping at customer expense

Negotiation Tip: For large orders, extend warranty period. Example: “We’re buying 2000 fuses; extend warranty from 2 years to 5 years.” Many manufacturers accommodate this for >$20,000 orders.

Lead Time Expectations:

| Szenario | Vorlaufzeit | Strategy |

|---|---|---|

| Standard ratings (10A, 15A, 20A) from distributor | 2-7 days | Order as needed |

| Standard ratings from manufacturer | 2-4 Wochen | Order in advance |

| Non-standard ratings or high volumes | 4-8 Wochen | Plan 2-3 months ahead |

| Custom specifications | 8-12 weeks | Rare for solar applications |

Spare Parts Stocking:

For every project, stock spares:

– Wohnen: 2-4 spares (20% of installed)

– Kommerziell: 10-20 spares (10% of installed)

– Utility: 50-100 spares (5-10% of installed) in on-site maintenance container

Reorder Point Calculation:

Reorder when spares reach:

– Minimum = (Monthly failure rate × Lead time in months) + Safety stock

– Example: 500 installed fuses, 0.5% annual failure = 2.5 failures/year = 0.2/month

– Lead time: 1 month

– Reorder point: (0.2 × 1) + 2 = 3 fuses (keep 5+ on hand)

| Anmeldung | Systemgröße | Recommended Brand | Product Series | Price Range | Key Reason |

|---|---|---|---|---|---|

| Budget Residential | 3-10 kW | Littelfuse Standard | KLKD | $10-15 | Cost-effective, good availability |

| Quality Residential | 10-20 kW | Eaton Bussmann | PV Series | $12-20 | Robust construction, good support |

| Small Commercial | 20-100 kW | Littelfuse Premium | KLDR | $15-25 | Time-delay options, reliable |

| Large Commercial | 100-500 kW | Mersen | FR14GG69V | $18-28 | Lowest TCO, best documentation |

| Utility Scale | > 500 kW | Mersen Only | FR Series | $12-22 volume | Industry standard, proven reliability |

| Rooftop Difficult Access | Any size | Mersen | FR Series | $18-28 | Minimize truck rolls, lowest failure rate |

| Ground Mount Easy Access | Any size | Littelfuse/Eaton | KLDR/PV | $12-22 | Balanced cost/quality, easy replacement |

Yes, for systems >10kW or installations with difficult service access. Total cost of ownership analysis shows premium fuses (0.1% failure rate) cost LESS over 10 years than budget options (2% failure rate) due to avoided truck rolls ($300-500 each). Example: 50-fuse system, premium costs $1,800 over 10 years vs budget $4,850 (2.7× more despite half the initial price). For residential systems <5kw with easy access where homeowner can replace fuses, standard tier ($12-20) offers better balance than either extreme. premium fuses also provide superior technical documentation and engineering support valuable for commercial projects.

Technically yes—all gPV-rated fuses meeting IEC 60269-6 are functionally interchangeable at same ratings. However, mixing is NOT recommended due to: (1) Coordination complexity—time-current curves differ slightly between brands, complicating protection studies; (2) Inventory management—need spare fuses for each brand; (3) Troubleshooting difficulty—visual distinction harder during maintenance; (4) Warranty complications—manufacturers may void warranty if failures attributed to mixed-brand coordination issues. Exception: Transitioning between brands over project lifetime is acceptable—mark old sections clearly, stock appropriate spares for each brand, update as-built documentation.

Counterfeits exist, especially for premium brands (Mersen, Littelfuse). Verification methods: (1) Purchase from authorized distributors only—check manufacturer website for distributor list; (2) Examine markings—genuine fuses have clear, permanently-etched ratings and logos; counterfeits use ink stamps that smudge; (3) Weight check—premium fuses weigh 40-60% more than counterfeits due to thicker ceramic and superior end caps; (4) Request certificates—genuine distributors provide test certificates with lot numbers matching fuse markings; (5) Verify hologram/QR codes if present; (6) Price check—if 40-50% below typical pricing, likely counterfeit. For large orders >$10,000, request sample testing at independent lab before accepting full shipment.

High altitude reduces air dielectric strength requiring voltage rating derating. At 3000m, apply 10% derating; at 4000m apply 20%. Solution: Oversize voltage rating. For 1000V DC system at 3000m, specify 1500V-rated fuses to maintain margin. Brand selection unchanged—Mersen FR Series handles altitude well due to superior arc-quenching sand. Some manufacturers (Mersen, SIBA) offer altitude-certified products tested at simulated high-altitude conditions. Request test data showing breaking capacity at reduced pressure. Temperature coefficient also affected—high-altitude locations often have extreme temperature swings (-20°C to +40°C daily), requiring robust ceramic construction favoring premium brands.

Time-delay fuses provide 2-5 second delay before opening, filtering brief overcurrent transients. Beneficial for: (1) Motor loads with inrush current; (2) Capacitive loads (inverter DC link capacitors) with charge inrush; (3) Cloud-edge enhancement (sudden irradiance spikes causing brief I_sc increase). NOT beneficial for standard PV strings—modules self-limit current and benefit from fast-acting protection. Recommendation: Use standard fast-acting fuses for string-level protection (99% of applications). Reserve time-delay for: combiner outputs feeding inverters with large capacitance, systems with frequent nuisance tripping despite proper sizing, special applications with documented transient issues. Cost: $15-25 for time-delay vs $10-18 standard (Littelfuse KLDR series).

Upfront purchase of 10-20% spares recommended for: (1) Volume discount qualification—adding spares reaches next price break; (2) Lot consistency—all fuses from same production batch ensures identical characteristics; (3) Lead time avoidance—no waiting during outages; (4) Price protection—locked in at project pricing, avoid future increases. Order-as-needed acceptable for: Large utility projects with on-site stores and overnight shipping contracts; short-term installations (<5 years); budget-constrained residential. storage requirements: keep fuses in original packaging temperature-controlled environment (avoid>40°C storage, humidity <70%). Properly stored fuses maintain specifications indefinitely—no degradation over 10-20 year storage.

Off-grid systems require more conservative fuse selection due to: (1) No grid backup—fuse failure stops ALL power (grid-tied continues via grid); (2) Harder service access—often remote locations with longer response times; (3) Battery fault currents—higher than PV-only grid-tied systems due to battery contribution. Recommendation off-grid: Oversize by one rating (use 25A instead of 20A if calculation gives 18A), select premium brands (failure consequences severe), add redundancy (parallel strings without fuses to maintain minimal power during fuse failure), stock 30% spares vs 10% grid-tied, choose brands with fastest delivery (Littelfuse in North America, Mersen in Europe). Grid-tied: Standard sizing adequate, can optimize for cost since grid provides backup during fuse replacement.

Selecting the best solar fuse transcends simple brand comparison—optimal choice balances quality tier (premium/standard/budget), application requirements (residential/commercial/utility), total cost of ownership analysis, and practical factors including service access difficulty, spare parts availability, and procurement volume discounts.

Key Selection Principles:

Quality Tier Matching: Premium fuses (Mersen, Littelfuse Pro) deliver lowest 10-year TCO despite 2-3× higher initial cost through superior reliability (0.1% failure rate vs 2% budget). Standard fuses (Littelfuse, Eaton Bussmann) provide excellent cost-performance balance for commercial applications. Budget fuses only cost-effective for temporary installations <5 years or ultra-cost-sensitive residential with easy service access.Application-Specific Optimization: Residential systems (3-20kW): Littelfuse Standard or Eaton Bussmann optimizes cost-quality ($10-18 per fuse). Commercial systems (20-500kW): Mersen premium justified by lower failure rate and superior support ($18-28). Utility scale (>500kW): Mersen exclusively for proven reliability and volume pricing ($12-22 with 40% discount). Difficult-access rooftops: Premium mandatory regardless of size to minimize truck rolls.

Procurement Strategy: Volume discounts dramatically affect economics—1000-piece orders achieve 35-40% savings. Standardize on single brand across multiple projects for additional 5-10% annual contract discounts. Negotiate extended warranties (2 years standard to 5 years) on large orders. Purchase 10-30% spares upfront to capture volume pricing and ensure lot consistency.

Physical Quality Indicators: Premium fuses feature high-grade steatite ceramic (3-4mm walls, clear ring when tapped), heavy brass end caps (50-100g), 99.8% pure silica sand. Budget fuses use thin porcelain (<2mm walls), stamped metal caps (20-40g), mixed-grain impure sand. request full test reports (20-50 pages) not just certificates—premium manufacturers provide extensive time-current and i²t data.

For electrical contractors, system designers, and procurement professionals, “best” fuse selection requires matching quality tier to project profile and calculating true lifecycle cost including failure rates, service costs, and lost production. Lowest initial price rarely equals lowest total cost—premium fuses consistently deliver superior value over 10-25 year solar project lifespans.

Related Selection Resources:

– Grundlagen der Solarmodul-Sicherung – Fundamental fuse technology

– Solar Fuses System Design – Multi-tier protection coordination

– DC Fuse Installation Guide – Proper installation practices

Unterstützung bei der Beschaffung: SYNODE maintains relationships with all major fuse manufacturers and can facilitate volume pricing, sample procurement, and technical qualification for projects >100kW. Contact our supply chain team for competitive bidding support and brand comparison analysis.

Zuletzt aktualisiert: Oktober 2025

Autor: SYNODE Procurement Engineering Team

Technische Überprüfung: Supply Chain Specialists, Field Service Engineers

Brands Analyzed: Mersen, Littelfuse, Eaton Bussmann, SIBA, Ferraz Shawmut, DF Electric

Schwerpunkt Stichwort: best solar fuse

URL Slug: best-solar-fuse-selection-guide-brand-comparison

Meta-Titel: Solar Fuse Selection: Voltage & Current Rating Criteria

Meta-Beschreibung: Best solar fuse selection guide: compare top brands Mersen Littelfuse Eaton Bussmann, evaluate quality indicators, price vs performance analysis, and decision matrices for optimal PV fuse choice.

Inhaltliche Ebene: Tier 3 (Supporting Content)

Umstellungstrichter: Top of Funnel (Bekanntheit)

Ziel-Wortzahl: 2800-4000 Wörter

Ziel Meerjungfrauen-Diagramme: 3

Bitte konfigurieren Sie diese in den Rank-Math-Einstellungen und löschen Sie dann dieses Feld vor der Veröffentlichung.

Yes for >10kW systems or difficult access. TCO analysis shows premium fuses (0.1% failure rate) cost LESS over 10 years than budget (2% failure rate) due to avoided truck rolls ($300-500 each). Example: 50-fuse system, premium $1,800 over 10yr vs budget $4,850 (2.7× despite half initial price). For residential <5kW with easy access, standard tier ($12-20) offers better balance. Premium provides superior documentation and engineering support for commercial projects.

Technically yes—all gPV IEC 60269-6 rated fuses functionally interchangeable at same ratings. However NOT recommended: (1) Coordination complexity—time-current curves differ between brands; (2) Inventory management—need spares for each brand; (3) Troubleshooting difficulty; (4) Warranty complications. Exception: Transitioning brands over project lifetime acceptable—mark sections clearly, stock appropriate spares, update documentation.

Counterfeits exist especially for premium brands. Verification: (1) Purchase from authorized distributors only (check manufacturer website); (2) Examine markings—genuine have clear etched ratings, counterfeits use smudging ink; (3) Weight check—premium 40-60% heavier than counterfeits; (4) Request certificates with matching lot numbers; (5) Verify holograms/QR codes; (6) Price check—40-50% below typical suggests counterfeit. Large orders >$10k: request sample testing at independent lab before accepting shipment.

High altitude reduces dielectric strength requiring voltage derating: 3000m=10% derating, 4000m=20%. Solution: Oversize voltage rating. For 1000V DC system at 3000m, specify 1500V fuses. Mersen FR Series handles altitude well with superior arc-quenching sand. Some manufacturers offer altitude-certified products tested at reduced pressure. Extreme temperature swings at altitude require robust ceramic construction favoring premium brands.

Time-delay (2-5 second delay) beneficial for: motor loads with inrush, capacitive loads (inverter DC link), cloud-edge enhancement transients. NOT beneficial for standard PV strings—modules self-limit current and benefit from fast-acting protection. Recommendation: Standard fast-acting for strings (99% of applications). Reserve time-delay for combiner outputs feeding large-capacitance inverters, frequent nuisance tripping cases. Cost: $15-25 time-delay vs $10-18 standard.

Upfront purchase 10-20% spares recommended for: (1) Volume discount qualification; (2) Lot consistency—same production batch ensures identical characteristics; (3) Lead time avoidance during outages; (4) Price protection. Order-as-needed acceptable for: large utility with on-site stores and overnight shipping, short-term installations <5yr, budget-constrained. Storage: Keep in original packaging, temperature-controlled environment (<40°C, <70% humidity). Properly stored fuses maintain specifications indefinitely.

Off-grid requires more conservative selection: (1) No grid backup—fuse failure stops ALL power; (2) Harder service access—remote locations; (3) Higher battery fault currents. Recommendation off-grid: Oversize by one rating (25A vs 20A if calculation=18A), select premium brands (failure consequences severe), add redundancy, stock 30% spares vs 10% grid-tied, choose brands with fastest delivery. Grid-tied: Standard sizing adequate, can optimize for cost since grid provides backup.