Adresse

304 North Cardinal

St. Dorchester Center, MA 02124

Heures de travail

Du lundi au vendredi : de 7h00 à 19h00

Le week-end : 10H00 - 17H00

Adresse

304 North Cardinal

St. Dorchester Center, MA 02124

Heures de travail

Du lundi au vendredi : de 7h00 à 19h00

Le week-end : 10H00 - 17H00

Understanding 2 string PV combiner box applications enables optimal component selection for small residential photovoltaic systems. This practical application guide examines when 2-string combiners provide value versus direct inverter connection, compact combiner design specifications, residential installation scenarios, cost-benefit analysis, and coordination with string inverters. Residential installers and homeowners will find clear decision criteria, practical design examples, and installation methods for small-scale combiner applications.

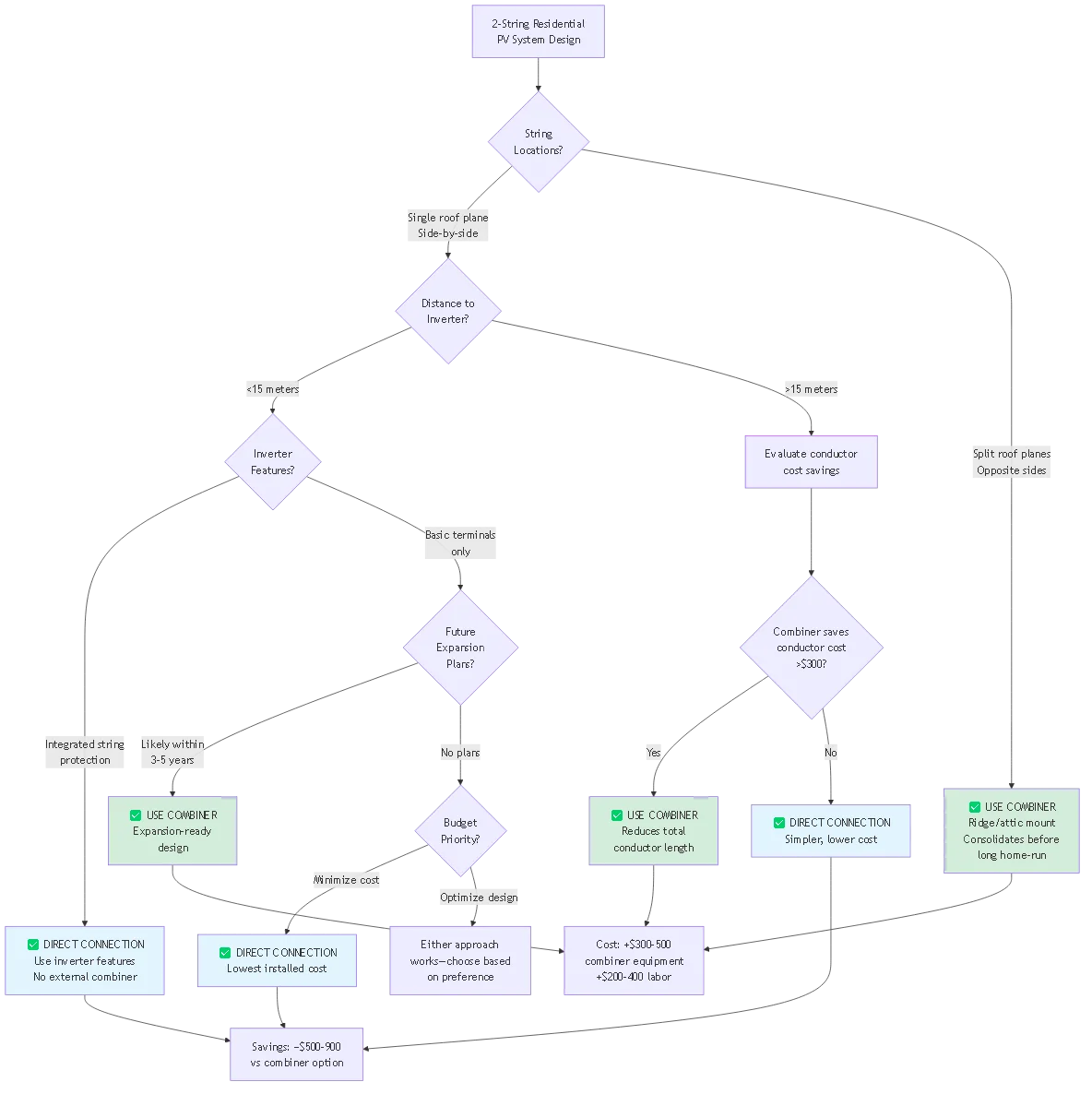

Two-string combiner boxes occupy unique position in residential solar market—large enough to benefit from consolidation yet small enough that direct inverter connection remains viable alternative. Understanding application scenarios where 2-string combiners optimize system design versus situations where simpler direct connection proves more practical ensures appropriate component selection maximizing value while controlling costs.

Two-string combiner boxes provide optimal solution for residential installations where string locations or inverter placement make consolidated connection preferable to individual home-runs. Specific scenarios benefit from 2-string combining approach despite additional equipment cost and installation complexity.

Split-roof residential arrays:

Homes with separate roof planes facing different directions (east/west, split gable) often deploy strings on distinct roof sections. Installing combiner at central location (roof ridge, attic access point) consolidates strings before single feeder run to ground-level inverter. This approach dramatically reduces conductor routing complexity compared to two separate home-runs requiring independent roof penetrations and conduit runs through building.

Example: East/west facing gable roof with 8 modules per side (two 8-module strings). Without combiner: two separate 40-meter home-runs from opposite roof sections to basement inverter requiring two roof penetrations and independent conduit systems. With combiner: two 10-meter string runs to ridge-mounted combiner, single 40-meter feeder to inverter using one roof penetration and conduit run. Installation labor savings ($400-800) plus reduced materials cost ($200-400) justify combiner equipment expense ($300-500).

Detached garage or carport systems:

Solar installations on detached structures (garage, carport, shed) located 20+ meters from main building inverter benefit from consolidation reducing long-distance conductor count. Two-string carport system requires expensive long-distance home-runs if strings connect directly to inverter. Carport-mounted combiner consolidates strings locally then single feeder crosses property to inverter location.

Calculate conductor cost comparison: Two 50-meter home-runs using 10 AWG copper (for 12A strings) = 200 meters total wire costing $2.50/meter × 200 = $500 conductor cost. Single 50-meter feeder using 8 AWG copper (for combined 24A output) = 100 meters × $3.00/meter = $300 conductor cost. Savings: $200 plus reduced conduit expense justifying combiner investment.

Inverter location constraints:

Some residential installations mount inverter in locations difficult to access with multiple conduit entries (interior wall-mounted inverters, compact utility rooms). Two-string combiner installed in accessible exterior location (outdoor wall, garage) simplifies inverter connection requiring single DC input rather than managing multiple string connections at inverter terminals. This approach particularly suits wall-mounted string inverters with limited terminal space or manufacturers recommending external combining for multi-string applications.

Future expansion planning:

Installing 2-string combiner during initial single-string installation enables seamless capacity expansion when homeowner adds second string within 3-5 years. Initial system uses one combiner input; second input remains capped until expansion occurs. Combiner pre-installation costs modest $300-500 but eliminates future combiner retrofit requiring system shutdown, permitting, and installation labor costing $1000-1500. Homeowners with available roof space and expansion plans within financing period benefit from expansion-ready combiner specification.

Two-string combiner boxes add complexity and cost appropriate only when specific application factors justify equipment investment. Many residential 2-string installations work better with direct inverter connection avoiding unnecessary combining equipment.

Close inverter proximity (<15 meters):

When string locations permit direct connection to nearby inverter, combiner elimination simplifies system reducing component count and potential failure points. String inverters with multiple independent MPPT inputs accommodate direct connection providing string-level monitoring and independent maximum power point tracking without external combining. Combiner omission saves equipment cost ($300-500) and installation labor ($200-400) totaling $500-900 system cost reduction.

Inverter with integrated string protection:

Modern string inverters increasingly integrate string-level overcurrent protection, DC disconnect, and surge protection eliminating external combiner requirements. These “all-in-one” inverters suit direct 2-string connection providing required protective functions within inverter enclosure. External combiner becomes redundant equipment duplicating inverter-integrated protection costing money without providing additional value.

Budget-constrained installations:

Residential systems prioritizing lowest possible cost benefit from eliminating optional components when application permits. Direct 2-string inverter connection using slightly longer individual home-runs costs less than adding combiner equipment despite increased conductor expense. For price-sensitive customers (first-time buyers, cash-limited homeowners), optimize cost through component minimization rather than elaborate multi-stage architectures appropriate for larger commercial installations.

Simple roof layouts:

Single roof plane with strings side-by-side permits easy parallel connection near array using simple junction box or inverter-integrated combining. These straightforward layouts lack geometric complexity justifying sophisticated combining equipment. Simple systems stay simple—adding combiner to already-simple installation creates unnecessary complexity without proportional benefit.

| Scénario | 2-String Combiner | Direct Connection | Recommendation |

|---|---|---|---|

| Split roof planes | ✅ Consolidates at ridge | ❌ Two separate home-runs | USE COMBINER |

| Detached structure (>30m) | ✅ Reduces long-run conductors | ❌ Expensive dual home-runs | USE COMBINER |

| Single plane, close inverter (<15m) | ⚠️ Adds cost, complexity | ✅ Simple, economical | DIRECT CONNECTION |

| Inverter w/ integrated protection | ⚠️ Duplicates inverter features | ✅ Uses inverter protection | DIRECT CONNECTION |

| Future expansion planned | ✅ Expansion-ready | ⚠️ Requires future retrofit | USE COMBINER |

💡 Aperçu clé : Two-string combiner decision depends more on installation geometry and future plans than technical necessity. Evaluate specific site conditions, inverter capabilities, conductor routing complexity, and expansion likelihood before defaulting to combiner equipment. Many residential 2-string systems work perfectly well with direct connection—combiner adds value only when specific application factors justify additional cost and complexity.

Two-string combiners use compact enclosures optimized for residential installations with space constraints and aesthetic considerations. Typical enclosure dimensions: 300×250×150mm (12×10×6 inches) providing adequate internal volume for two string fuse holders, small busbar assembly, terminals, and optional surge protection while maintaining modest external footprint suitable for visible residential locations.

Mounting configuration options:

Wall-mounted outdoor: Most common configuration mounts combiner on exterior wall near array using 2-4 mounting brackets. Select NEMA 3R or better enclosure rated for outdoor exposure. Mount at comfortable working height (1.4-1.6 meters) for inspection and maintenance access. Orient enclosure door away from prevailing weather direction minimizing water intrusion. Provide adequate clearance below combiner (minimum 300mm) for conduit entries and conductor bending radius.

Roof-mounted: Suitable for split-roof scenarios where combiner mounts at ridge or central roof location. Use roof-rated enclosure designed for direct mounting on roofing surface including appropriate flashing kit preventing water infiltration. Some jurisdictions prohibit roof-mounted electrical equipment for safety and maintenance accessibility—verify local code requirements before specifying roof mounting.

Attic/soffit-mounted: Interior attic or soffit mounting protects combiner from weather while maintaining accessibility. Requires adequate ventilation preventing excessive internal temperature from attic heat. Specify temperature-expanded operating range (−10°C to +70°C) for attic installations experiencing temperature extremes. Ensure access pathway allows safe maintenance without requiring uncomfortable working positions or unsafe ladder operations.

Post/rack-mounted: Ground-mount arrays or carport systems benefit from post-mounted combiners at array perimeter. Use unistrut or dedicated mounting rack elevating combiner above ground level (minimum 500mm) preventing water pooling and providing convenient service access. Post mounting suits utility easement or agricultural installations where wall-mount options unavailable.

Two-string combiners require individual string overcurrent protection per NEC 690.9(B) preventing backfeed current damage during fault conditions. Despite only two strings, protection remains mandatory when strings parallel-connect at common busbar. Compact combiner designs accommodate protection devices within limited internal volume.

Fuse-based protection:

Most 2-string combiners use gPV-rated fuses providing economical, space-efficient overcurrent protection. Standard fuse ratings for residential strings: 15A or 20A matching string short-circuit current per NEC 690.9(B) requirements (Isc × 1.56 = fuse rating). Common fuse formats:

– 10×38mm cylindrical fuses: Industry-standard size mounting in compact fuse holders occupying 30-35mm width per string. Total space requirement: 70mm for two fuses plus mounting hardware.

– Finger-safe fuse holders: Touch-proof design prevents accidental contact with energized fuse terminals during service. Required per NEC 110.27 for readily accessible locations.

– Status indication: LED indicators showing fuse continuity simplify troubleshooting identifying blown fuses without voltage testing.

Circuit breaker alternatives:

Some premium 2-string combiners use DC-rated circuit breakers instead of fuses providing resetable protection and convenient testing disconnect. Breakers cost 3-4× more than fuses ($80-120 per pole vs $20-30) but eliminate replacement expense after fault events. Two-pole breakers (protecting both positive and negative conductors) occupy 90-110mm width requiring larger enclosure than fuse-based designs.

Select breakers explicitly rated for DC operation at system voltage—AC breakers cannot safely interrupt DC arcs lacking zero-crossing for arc extinction. Verify breaker listing includes “DC” rating per UL 489 or IEC 60947-2 standards at or above system voltage.

Two-string combiner busbar requirements remain modest compared to larger multi-string designs enabling simplified construction and compact packaging. Busbar cross-section sized for combined string current: For two 12A strings, combined current = 24A × 1.25 (NEC factor) = 30A continuous rating required.

Busbar sizing calculation:

At 1.5 A/mm² current density (copper, natural convection cooling): Required area = 30A / 1.5 = 20mm². Typical busbar dimensions: 2mm thick × 10mm wide = 20mm² meets requirement. Small cross-section allows bent busbar fitting within compact enclosure depth. Premium combiners use tinned copper preventing oxidation maintaining low contact resistance over decades.

Terminal specifications:

String input terminals handle individual string current (12A typical) while output terminals accommodate combined current (24A typical). Common terminal configurations:

– Input terminals: Spring-cage or screw-clamp style accepting 14-10 AWG conductors typical for string wiring

– Output terminals: Compression-style accepting 10-6 AWG conductors typical for combiner-to-inverter feeder

– Ground terminal: Lug-style accepting 10 AWG ground conductor, prominently marked with green identifier

Clearly labeled terminals identify string 1, string 2, output positive (+), output negative (−), and ground preventing wiring errors during installation. Pre-printed labels within enclosure door showing terminal identification and basic wiring diagram simplify installation for technicians unfamiliar with specific combiner model.

Understanding total cost of 2-string combiner installation versus direct connection alternatives enables informed design decisions balancing functionality against budget constraints. Break down costs into equipment, materials, and labor categories for accurate comparison.

Combiner equipment costs:

– Basic 2-string combiner (fuse-based, NEMA 3R): $300-450

– Premium combiner (breaker-based, monitoring): $500-750

– SPD integration (if included): Add $100-200

– Mounting hardware: $30-60

Additional materials:

– Conduit and fittings: $50-150 (depending on run length)

– Conductor (combiner to inverter): $100-200

– Wire management and labels: $20-40

– Total materials: $170-390 typical

Installation labor:

– Combiner mounting and wiring: 2-3 hours @ $75-125/hour = $150-375

– Conduit installation: 1-2 hours = $75-250

– Testing and commissioning: 0.5-1 hour = $40-125

– Total labor: $265-750 typical

Total installed cost: $735-1590 for complete 2-string combiner installation

Direct connection alternative costs:

– String conductors (two home-runs): $200-400 (incremental cost vs combiner scenario)

– Conduit and fittings: $100-250

– Installation labor: $200-400 (shorter working time, but two circuits)

– Total direct connection premium: $500-1050 vs base system with combiner

Cost differential analysis:

Combiner installation typically costs $700-1600 total. Direct connection to inverter adds $500-1050 in conductor and labor costs versus single combiner output feed. Net combiner cost premium: $200-550 depending on specific installation geometry. Combiner justifies when geometric complexity, future expansion value, or installation simplification exceeds this modest premium.

###Energy Loss Considerations

Two-string combiner adds minimal series resistance creating negligible power loss during normal operation. Quality combiners specify internal resistance <0.5mΩ producing voltage drop far below significance threshold.

Calculate annual energy loss from combiner:

Combiner internal resistance: 0.3mΩ (typical quality unit)

Average operating current: 18A (75% of 24A maximum)

Voltage drop: V = I × R = 18A × 0.0003Ω = 0.0054V

At 400V system voltage: Loss = 0.0054V / 400V = 0.0014% (negligible)

Annual energy production: 8000 kWh (typical 5kW residential)

Combiner loss: 8000 kWh × 0.000014 = 0.11 kWh/year

Energy value @ $0.12/kWh: $0.01/year (literally cents)

Combiner resistance losses prove utterly insignificant compared to conductor voltage drop, inverter conversion losses, or soiling/shading impacts. Don’t over-optimize combiner selection chasing theoretical losses—focus on practical installation factors, cost optimization, and reliability instead.

Two-string combiner investment provides value beyond immediate installation through enhanced safety, simplified troubleshooting, and expansion flexibility. Quantify these benefits evaluating total cost of ownership over system lifetime.

Safety and code compliance value:

Combiner-based designs clearly satisfy NEC 690.9(B) overcurrent protection requirements with obvious, inspectable fuse or breaker protection visible during electrical inspection. Direct-connection designs may require embedded inverter-internal protection creating inspection ambiguity and potential approval delays. Combiner installation eliminates code compliance questions ensuring first-time inspection approval (value: $200-500 avoiding re-inspection fees and delays).

Troubleshooting efficiency:

Centralized combiner location provides convenient test point for string performance evaluation without accessing roof array or opening inverter enclosure. Technician can quickly verify individual string voltage and current at ground-accessible combiner location diagnosing problems (shading, soiling, module failure) without hazardous roof work. Estimated troubleshooting time savings: 0.5-1.0 hours per service call @ $100-150/hour = $50-150 per incident over 25-year lifetime (value: $250-750 for 5 service events).

Expansion flexibility:

Combiner with spare capacity enables seamless future array expansion adding strings without combiner replacement. Initial 1-string system using 2-string combiner accommodates second string addition costing only module and mounting equipment (~$2500-3500) versus requiring new combiner installation during expansion (additional $1000-1500). Expansion flexibility value: $1000-1500 if exercised within system life.

Total quantified long-term value: $1450-2750 over 25 years justifying $200-550 combiner cost premium versus direct connection. However, value realization requires expansion actually occurring and service events requiring troubleshooting—theoretical value may not materialize for problem-free systems in fixed configurations.

Proper 2-string combiner specification requires understanding inverter DC input requirements ensuring compatibility and optimal performance. Modern string inverters specify multiple DC input parameters combiner design must accommodate.

DC input voltage range:

Inverters specify minimum and maximum DC input voltages defining operational window. Combiner output voltage (equal to string voltage) must fall within inverter range under all operating conditions:

– Minimum inverter input voltage: Typically 150-200V for residential inverters

– String voltage at maximum power point (Vmpp): Typically 300-400V for 12-module 600V systems

– Maximum inverter input voltage: Typically 500-600V for residential units

– String open-circuit voltage (Voc): Typically 480-550V at standard conditions

Verify string Voc(cold) including temperature compensation doesn’t exceed inverter maximum input during winter operation. If calculated cold Voc = 580V but inverter maximum = 600V, adequate margin exists. Insufficient margin risks inverter shutdown or damage during cold sunny mornings.

DC input current capacity:

Inverter input current rating must accommodate combined string output without exceeding maximum. Most residential inverters specify 11-13A per MPPT input suitable for single-string connection. Combined 2-string current (24A typical) exceeds single input capacity requiring inverter with sufficient current rating or dual MPPT inputs connecting strings separately.

When using 2-string combiner, verify inverter accepts combined current on single input or specify inverter with appropriate current rating. Some designs use 2-string combiner feeding dual-MPPT inverter with strings connecting to separate MPPT channels through combiner output cable split at inverter—verify manufacturer approval for this configuration before implementing.

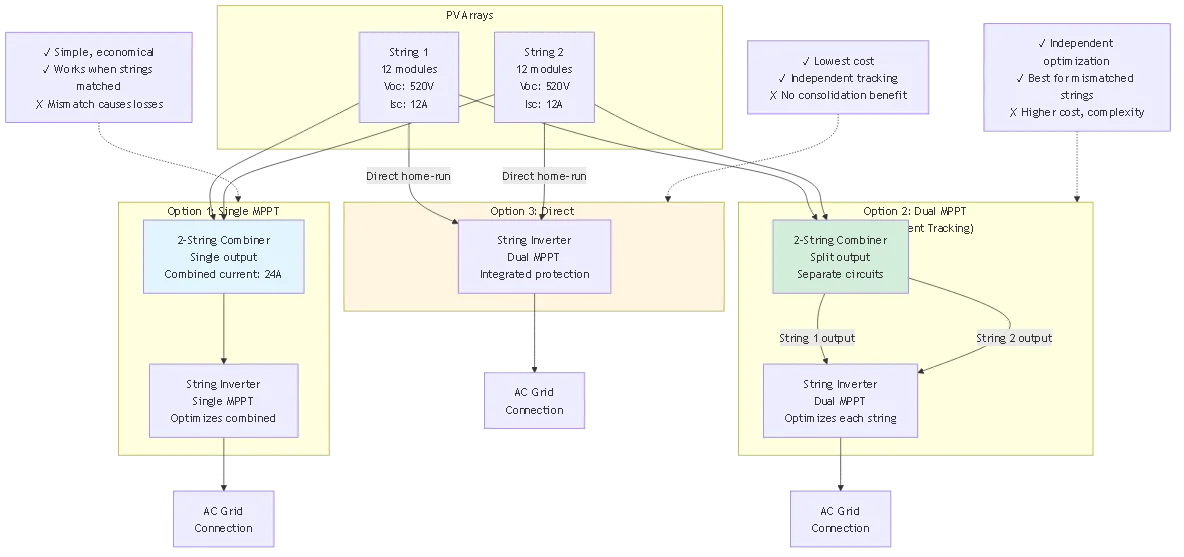

Maximum power point tracking (MPPT) configuration affects 2-string system performance especially when strings experience different conditions (shading, orientation, soiling). Consider MPPT architecture during combiner design ensuring optimal energy harvest.

Single MPPT operation:

Traditional 2-string combiner combines strings at common busbar feeding single inverter MPPT input. This approach works well when strings experience identical conditions (same orientation, no differential shading). MPPT optimizes for combined string voltage-current characteristic producing single maximum power point.

Limitation: If one string experiences shading or soiling reducing output, combined MPPT operates at compromise point not optimal for either individual string. Energy loss depends on mismatch severity—minor differences cause 1-3% loss while severe shading can cause 10-15% loss as MPPT cannot simultaneously optimize both strings.

Dual MPPT operation:

Premium inverters provide independent MPPT channels allowing separate string optimization. While both strings connect through combiner for consolidation and protection, output splits at inverter providing separate inputs to independent MPPT circuits. Each MPPT independently optimizes its string regardless of other string conditions maximizing energy harvest from mismatched strings.

Implementation requires specialized combiner providing split output (two output conductor pairs) or external splitter at inverter location. Additional complexity and cost ($100-200 for split combiner) justifies only for installations with significant string mismatch (east/west facing strings, partial shading on one string).

DC optimizers as alternative:

Some installations use module-level DC optimizers (one per module) performing individual optimization before string-level combination. Optimizers enable string-level combination without MPPT losses but add significant cost ($40-60 per optimizer × 20-24 modules = $800-1440 total). Optimizer approach suits severely shaded locations or complex roof layouts where multiple orientations combine in single string. However, most residential 2-string applications lack sufficient complexity justifying optimizer expense.

Proper conductor selection and routing ensures efficient power transfer and code compliance for 2-string residential systems. While smaller than commercial installations, residential systems demand same attention to conductor sizing methodology and installation quality.

String input conductors:

Size string conductors per NEC 690.8(B) requiring minimum 156% of string short-circuit current: For 12A Isc strings, minimum conductor = 12A × 1.56 = 18.72A capacity. Apply temperature derating per NEC 310.15(B)(2)(a) for rooftop conduit (often 60°C ambient or higher): 18.72A / 0.58 (derating factor for 75°C conductor at 60°C ambient) = 32.3A required conductor capacity. Select 10 AWG copper (30A @ 75°C, 40A @ 90°C) providing adequate capacity after derating.

Combiner output conductors:

Output conductors carry combined string current requiring larger gauge than inputs. For two 12A strings: Combined current = 24A × 1.56 = 37.4A minimum capacity. With temperature derating: 37.4A / 0.58 = 64.5A required. Select 6 AWG copper (65A @ 75°C) providing adequate capacity. Alternatively, verify installation temperature derating allows smaller gauge if combiner-to-inverter run occurs in cooler location (interior wall, underground conduit).

Conductor routing guidelines:

– Install string conductors in separate conduits from AC wiring per NEC 690.31(C)

– Use continuous conductors without splices where possible maintaining circuit integrity

– Provide service loops (300mm) at combiner and inverter allowing terminal access without conductor tension

– Support conductors every 1.4 meters (54 inches) per NEC 300.11 preventing sag and mechanical stress

– Label conductors at both ends identifying circuit (“String 1 Positive”, “Combiner Output Negative”) simplifying troubleshooting

Proper grounding establishes safe electrical reference and provides fault current path protecting personnel and equipment. Two-string combiners require careful attention to grounding integration with overall system grounding architecture.

Equipment grounding conductor:

NEC 690.43 requires equipment grounding conductor (EGC) connecting all metal enclosures in DC circuit. Size EGC per NEC 250.122 based on overcurrent protection device rating: For 20A string fuses, Table 250.122 specifies 12 AWG copper minimum. However, PV systems often benefit from oversized EGC (10 AWG or 8 AWG) reducing ground impedance improving surge protection effectiveness.

Run EGC with circuit conductors in same conduit maintaining parallel routing minimizing ground loop formation. Terminate EGC at combiner ground terminal using compression lug (not solder) ensuring gas-tight connection. Continue EGC from combiner to inverter maintaining ground continuity through complete DC circuit.

System grounding (if applicable):

Some residential systems use grounded DC circuits (negative or positive conductor bonded to ground at single point). NEC 690.41 establishes requirements for grounded PV systems including ground fault detection and DC disconnect requirements. Verify combiner design accommodates grounded system requirements if applicable—some combiners designed for ungrounded systems require modification for grounded applications.

Array frame bonding:

Module frames and mounting structures require bonding to equipment grounding system per NEC 690.43(B). While separate from combiner grounding, ensure combiner equipment ground connects to same grounding electrode system as array frame bonding creating common reference without ground loops. Use bonding jumpers rated for outdoor exposure and listed for PV grounding applications (WEEB or similar).

Complete systematic commissioning procedure verifying correct installation before finalizing 2-string combiner system. Testing identifies wiring errors, poor connections, or specification problems correctable before energization.

Pre-energization tests:

1. Continuity verification: Measure resistance through each string circuit from module terminals through combiner to inverter input. Target <1Ω confirms good connections without unexpected resistance.

2. Résistance de l'isolation: Use megohmmeter measuring resistance between positive busbar and ground, negative busbar and ground. Target >1MΩ confirms adequate insulation integrity without unintended ground paths.

3. Polarity check: Verify positive string conductors connect to positive busbar, negative to negative. Reversed polarity may not cause immediate failure but creates protection coordination issues.

4. Ground continuity: Measure resistance from combiner enclosure through EGC to inverter ground and system grounding electrode. Target <1Ω confirms adequate ground path.

Energization procedure:

1. With modules covered or shaded, verify zero voltage at combiner inputs using multimeter rated for DC voltage measurement.

2. Uncover/unshade string 1 verifying expected open-circuit voltage appears at combiner input 1 terminals.

3. Verify correct polarity: positive conductor shows voltage relative to negative conductor matching expected polarity.

4. Repeat for string 2 confirming both strings present expected voltage with correct polarity.

5. Close string fuses/breakers verifying voltage appears at combiner output terminals.

6. Measure output current under full sun conditions (>800 W/m² irradiance) confirming combined string current approximates sum of individual string outputs (within 10%).

7. Monitor combiner temperature under full sun load for 30 minutes. Internal temperature should stabilize <20°C above ambient. Excessive heating indicates poor connections or undersized components requiring investigation.

Use 2-string combiner when installation geometry makes consolidation beneficial: split roof planes requiring ridge-mounted combining, detached structures with long runs to main building inverter (>30m), or future expansion plans justifying expansion-ready combiner installation. Combiner proves valuable when conductor cost savings from single combined output versus two separate home-runs exceeds combiner equipment cost ($300-500) plus installation labor premium ($200-400).

Direct connection works better for simple installations: single roof plane with strings side-by-side, close inverter proximity (<15m allowing economical direct runs), or inverters with integrated string protection eliminating external combiner functions. Budget-constrained installations prioritizing lowest cost benefit from direct connection eliminating combiner equipment expense. Evaluate specific site geometry, conductor routing requirements, and future plans determining optimal approach for your application.

Size string input conductors per NEC 690.8(B) at 156% of string short-circuit current. For typical 12A Isc strings: minimum capacity = 12A × 1.56 = 18.72A. Apply temperature derating for rooftop installations—at 60°C ambient, 75°C conductor requires 32A capacity suggesting 10 AWG copper. Output conductors carry combined current: 24A × 1.56 = 37.4A minimum requiring 6 AWG copper (65A @ 75°C) after temperature derating.

Equipment grounding conductor sizes per NEC 250.122 based on overcurrent protection rating. For 20A string fuses: minimum 12 AWG copper but recommend 10 AWG or 8 AWG for improved surge protection. Verify conductor insulation temperature rating (75°C or 90°C) matches installation environment and apply appropriate derating factors per NEC 310.15. Oversized conductors minimize voltage drop improving system efficiency—calculate voltage drop ensuring <2% from array to inverter.

Most 2-string combiners accommodate optional surge protective device (SPD) integration providing centralized transient overvoltage protection. Specify SPD Type 2 (In rated, 8/20μs waveform) suitable for combiner location in protected building environment or Type 1 (Iimp rated, 10/350μs) for exposed outdoor locations potentially experiencing direct lightning energy. MCOV rating must exceed maximum system voltage with margin: MCOV ≥ 1.25 × Voc(cold).

Integrated SPD installation costs $100-200 additional for device plus modest installation labor. SPD integration simplifies surge protection compared to separate SPD enclosure reducing component count and installation complexity. However, verify combiner has adequate internal space and mounting provisions for SPD—some ultra-compact combiners lack space for SPD integration requiring external SPD installation. NEC 690.35 mandates surge protection for most residential PV systems making SPD integration valuable feature.

Quality 2-string combiners provide 20-25 year service life matching photovoltaic system operational lifetime when properly specified and installed. Passive components (enclosure, busbar, terminals) exhibit minimal degradation under normal conditions. Active protection components (fuses, circuit breakers, SPDs) require periodic inspection and potential replacement throughout system life.

String fuses typically survive system life unless activated by fault conditions. However, proactive fuse inspection every 5-10 years identifies age-related degradation allowing preventive replacement. SPDs degrade with each surge event—typical lifespan 5-10 years depending on lightning activity requiring replacement based on manufacturer specifications or surge counter indications. Environmental exposure affects longevity—coastal installations experience accelerated corrosion while climate-controlled indoor installations easily exceed 25-year lifespan.

Premium combiner investments ($500-750) justify through extended warranties (5-10 years), superior materials (stainless steel, tinned copper), and better documentation compared to budget alternatives ($300-450) with 1-2 year warranties. Calculate total cost of ownership including potential replacement labor and downtime—premium combiners often cost less over 25-year system lifetime despite higher initial price.

Microinverter systems connect each module to dedicated microinverter performing DC-to-AC conversion at module level eliminating DC combining requirements. Two-string combiner becomes unnecessary since no string-level DC consolidation occurs—system architecture uses parallel AC connections instead. Microinverter installations simplify DC wiring but introduce complexity on AC side requiring proper branch circuit management.

Power optimizer systems use module-level DC-DC converters optimizing each module independently before string-level combination. While optimizers enable advanced monitoring and individual module control, DC combining still occurs at string level potentially benefiting from combiner box for string consolidation and protection. However, many optimizer-based inverters include integrated string combining eliminating external combiner requirement. Verify system architecture and manufacturer recommendations before specifying combiner with optimizer-based designs.

Traditional string inverter systems provide clearest use case for 2-string combiner boxes consolidating strings at DC level before single inverter converts combined power to AC. This proven architecture remains most common for residential installations offering good cost-performance balance without complexity of module-level electronics.

Complete 2-string combiner installation typically costs $700-1600 including equipment, materials, and labor. Equipment costs $300-750 depending on specifications: basic fuse-based NEMA 3R combiner ($300-450), premium breaker-based with monitoring ($500-750). Materials including conduit, conductors, mounting hardware, and wire management add $150-400. Professional installation labor for mounting, wiring, conduit, and commissioning totals $250-750 depending on site accessibility and installation complexity.

Cost differential versus direct inverter connection ranges $200-550—combiner costs more initially but saves conductor and conduit expense for long combined output run versus two separate string home-runs. Combiner justifies cost when geometric complexity, future expansion value, or installation simplification exceeds premium. Budget-focused installations with simple geometry and no expansion plans save money through direct connection approach.

Request detailed quotes from multiple installers comparing combiner versus direct connection scenarios. Ensure quotes include all materials, labor, permits, and commissioning testing providing accurate total cost comparison. Low-cost quotes omitting essential components (SPDs, proper conductor sizing, quality terminals) create false savings leading to code violations or reliability issues requiring expensive corrections.

Two-string PV combiner box applications require careful evaluation balancing technical requirements, installation geometry, future expansion plans, and cost constraints. Understanding when 2-string combiners add value versus situations where direct connection proves more practical enables optimal residential solar system design matching component selection to specific application needs.

Principaux enseignements :

1. Two-string combiners optimize split-roof installations, detached structures, and expansion-ready designs where consolidation benefits justify equipment cost

2. Direct connection suits simple single-plane arrays with close inverter proximity (<15m) and inverters with integrated string protection 3. Compact combiner specifications require 20-40mm² busbar, 10-6 AWG conductors, and NEMA 3R or better enclosure for outdoor residential mounting 4. Installation cost premium $200-550 versus direct connection justified by geometric complexity, conductor savings, or expansion flexibility 5. Proper coordination with inverter MPPT architecture ensures optimal energy harvest especially for mismatched string conditions

Systematic application analysis considering installation-specific factors rather than defaulting to combiner or direct connection ensures appropriate component selection optimizing residential solar system design for cost, performance, and long-term value.

Related Resources:

– What is a Combiner Box? PV System Fundamentals

– PV Combiner Box Selection: String Count Sizing Guide

– PV Combiner Box Wiring: Installation Standards

Ready to design optimal 2-string systems for residential installations? Contact our residential solar design team for application-specific combiner recommendations, cost-benefit analysis, and installation guidance ensuring your 2-string systems deliver maximum value for homeowners.

Dernière mise à jour : November 2025

Auteur : L'équipe technique de SYNODE

Révisé par : Residential PV Installation Department