Adresse

304 North Cardinal

St. Dorchester Center, MA 02124

Heures de travail

Du lundi au vendredi : de 7h00 à 19h00

Le week-end : 10H00 - 17H00

Adresse

304 North Cardinal

St. Dorchester Center, MA 02124

Heures de travail

Du lundi au vendredi : de 7h00 à 19h00

Le week-end : 10H00 - 17H00

String combiner box specifications define the critical parameters that determine proper protection, environmental suitability, and long-term reliability of photovoltaic string consolidation equipment. Understanding these specifications—particularly NEMA versus IP enclosure ratings—enables informed selection decisions that match equipment capabilities to installation requirements and code compliance mandates.

Modern string combiner boxes integrate multiple specification domains: environmental protection ratings (NEMA/IP codes), electrical characteristics (voltage/current ratings), physical configuration (busbar design), component integration (Fusible DC holders, breaker positions), and monitoring capabilities. Each specification category addresses specific performance requirements that collectively determine the combiner’s suitability for residential, commercial, or utility-scale applications.

This comprehensive specification guide examines the technical parameters that define string combiner box capabilities, provides detailed comparisons of NEMA and IP rating systems, explains material selection criteria, and presents systematic methodology for matching combiner specifications to application requirements. You’ll learn how to interpret specification sheets, verify code compliance, and select optimal configurations for diverse installation environments.

💡 Specification Principle: Proper string combiner box selection requires understanding that NEMA and IP ratings measure different environmental protection aspects—NEMA includes corrosion resistance and ice formation, while IP focuses solely on ingress protection from solids and liquids.

The National Electrical Manufacturers Association (NEMA) rating system provides comprehensive environmental protection classification specifically developed for North American electrical equipment installations. NEMA ratings address multiple environmental factors beyond simple ingress protection.

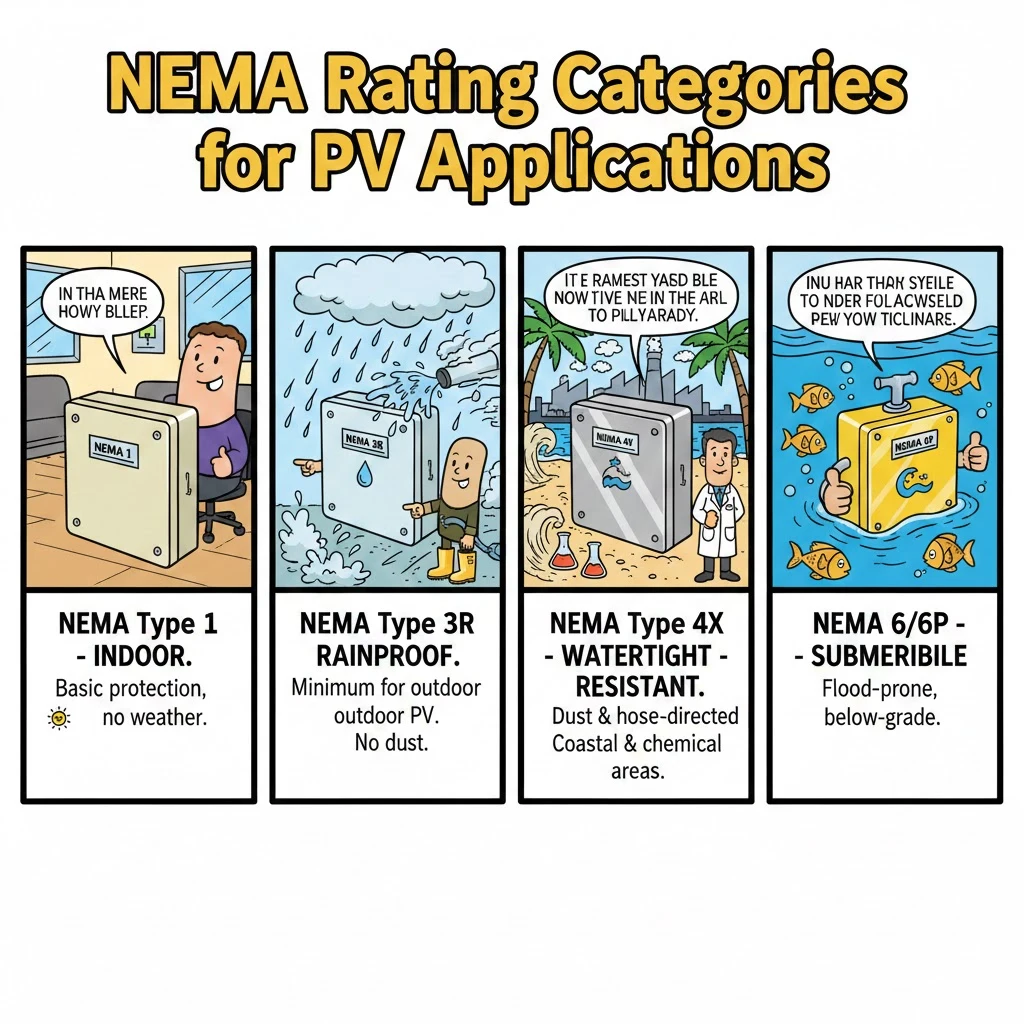

NEMA Type 1 – Indoor general purpose enclosures provide basic protection against incidental contact with enclosed equipment. These non-weatherproof enclosures suit only indoor installations in climate-controlled environments. Not applicable for string combiner boxes as PV arrays require outdoor ratings.

NEMA Type 3R – Rainproof enclosures designed for outdoor use provide protection against falling rain, sleet, and external ice formation. Type 3R represents the minimum acceptable rating for outdoor string combiner boxes in most residential and commercial rooftop installations. The ‘R’ designation indicates rain protection without dust-tight sealing or protection against windblown dust.

NEMA Type 4 – Watertight enclosures offer protection against splashing water, hose-directed water, and windblown dust/rain. Type 4 enclosures suit installations near water features, in areas with frequent washing operations, or locations with significant dust exposure. The sealed construction provides superior environmental protection compared to Type 3R.

NEMA Type 4X – Corrosion-resistant watertight enclosures combine Type 4 environmental protection with enhanced corrosion resistance through stainless steel, fiberglass, or aluminum construction. Type 4X represents the optimal choice for coastal installations, chemical processing facilities, or areas with significant atmospheric corrosivity.

NEMA Type 6/6P – Submersible enclosures protect against temporary/prolonged submersion and provide the highest liquid ingress protection. Rarely specified for string combiner boxes unless installation locations face flood risks or require below-grade mounting in vaults.

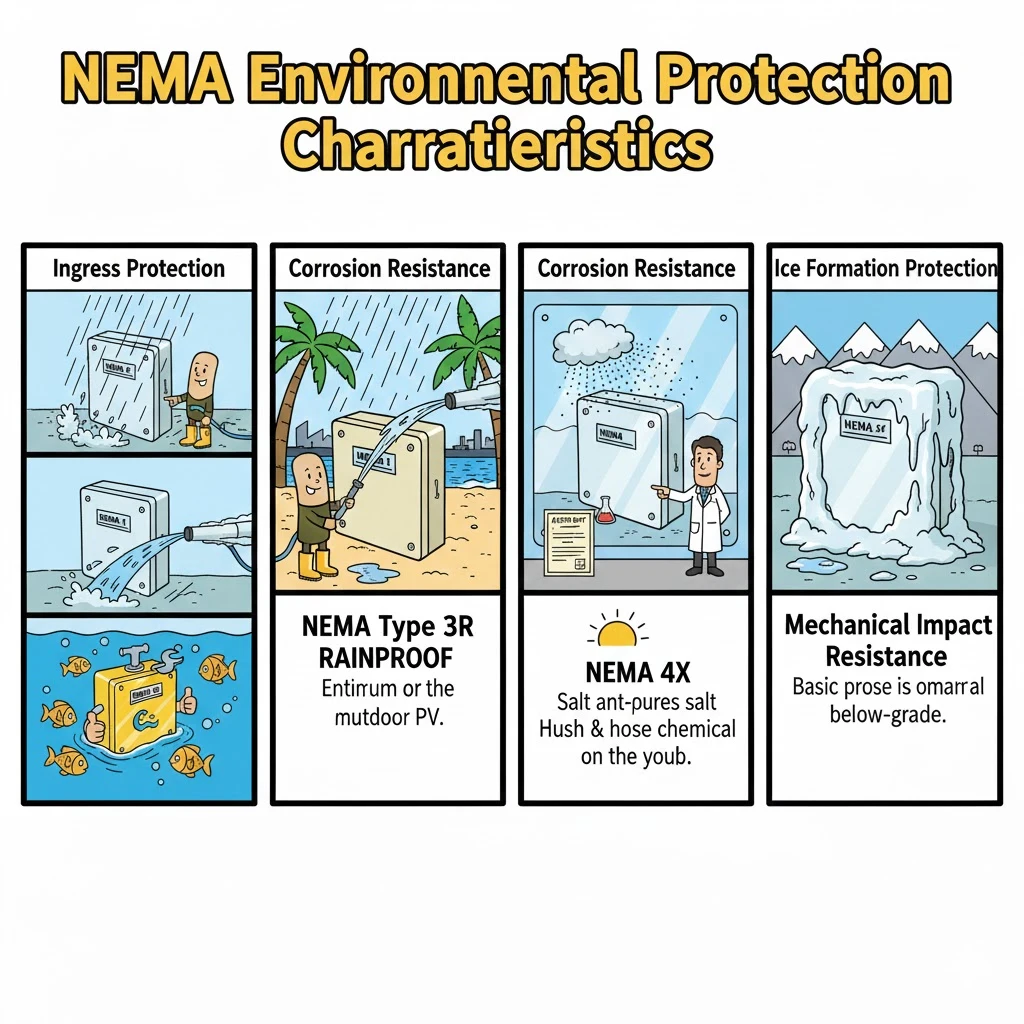

NEMA ratings encompass multiple protection attributes beyond ingress protection. Each rating certifies performance against specific environmental challenges.

Protection contre les infiltrations: NEMA enclosures provide varying degrees of protection against solid object and liquid ingress. Type 3R prevents vertical rain entry but allows ventilation. Type 4/4X provides complete sealing against windblown rain and pressurized water jets. Type 6/6P withstands complete submersion.

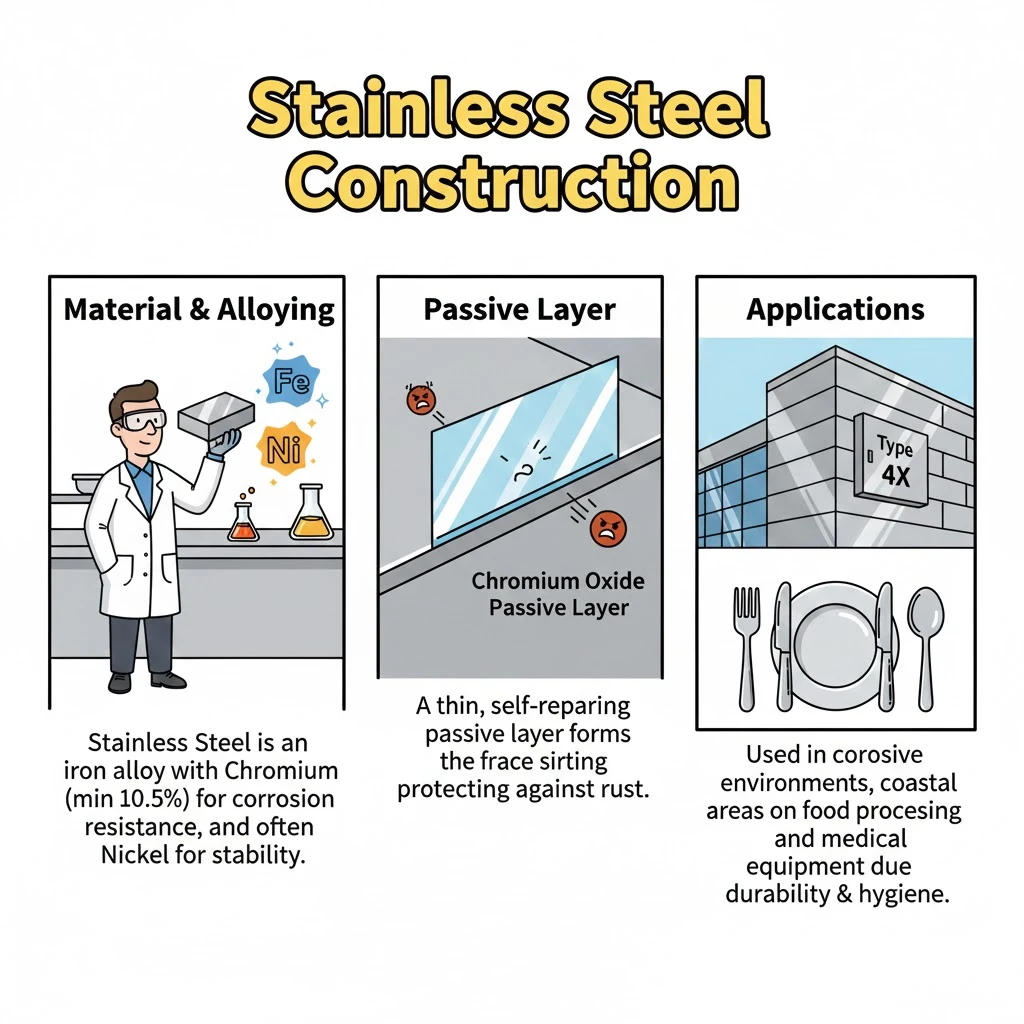

Corrosion Resistance: NEMA Type 4X specifically addresses corrosion resistance through material specification. The ‘X’ suffix mandates stainless steel (typically 304 or 316), aluminum alloy, or non-metallic materials with demonstrated corrosion resistance. Type 4X enclosures maintain integrity in salt spray environments per ASTM B117 testing.

Ice Formation Protection: NEMA Type 3R, 4, and 4X ratings include external ice formation resistance, ensuring enclosure functionality after ice accumulation and subsequent melting. This characteristic proves critical for string combiner boxes in northern climates experiencing freeze-thaw cycles.

Mechanical Impact Resistance: NEMA ratings incorporate structural strength requirements, though not explicitly quantified like IK codes. Type 4/4X enclosures provide superior impact resistance through heavier gauge materials and reinforced construction compared to Type 3R.

Gasket Systems: Type 4 and 4X enclosures employ continuous gasket seals around door perimeters, typically using neoprene, EPDM, or silicone materials. Gasket compression provides the watertight seal distinguishing Type 4 from Type 3R. Gasket aging from UV exposure and thermal cycling requires periodic inspection and replacement.

Door Latch Mechanisms: NEMA Type 4/4X requires positive latching mechanisms maintaining gasket compression. Common designs include captive quarter-turn latches, compression latches with key locks, or multi-point latching for large enclosures. Type 3R may use simple hinged doors with basic hasps.

Cable Entry Sealing: String combiner boxes require sealed cable entry points maintaining the NEMA rating. Type 4/4X installations use compression glands, liquid-tight conduit fittings, or cord grips with appropriate IP ratings. Proper cable entry sealing often represents the weakest point in maintaining enclosure ratings.

| Type NEMA | Rain Protection | Protection contre la poussière | Corrosion Resistance | Application typique |

|---|---|---|---|---|

| Type 3R | Falling rain only | Minimal | Standard paint | Residential rooftop |

| Type 4 | Windblown rain, hose-directed | Complete seal | Standard paint | Commercial ground-mount |

| Type 4X | Windblown rain, hose-directed | Complete seal | Stainless/fiberglass | Coastal installations |

| Type 6P | Submersion resistant | Complete seal | Enhanced | Flood-prone areas |

🎯 Conseil de pro: NEMA Type 3R enclosures cost 30-40% less than Type 4X but sacrifice dust sealing and corrosion resistance—specify Type 3R only for clean, non-coastal residential installations where cost optimization outweighs environmental protection.

The International Protection (IP) rating system defined by IEC 60529 provides standardized classification for ingress protection against solids and liquids. IP ratings use a two-digit code specifically quantifying protection levels without addressing corrosion, icing, or other environmental factors.

The IP code format follows: IP[First Digit][Second Digit], where the first digit (0-6) indicates solid particle protection and the second digit (0-9) indicates liquid ingress protection. Optional third letters provide supplementary information but rarely appear in string combiner box specifications.

First Digit – Solid Ingress Protection:

– IP0X: No protection against solid objects

– IP1X: Protection against objects >50mm (hand contact)

– IP2X: Protection against objects >12.5mm (finger contact)

– IP3X: Protection against objects >2.5mm (tools, wires)

– IP4X: Protection against objects >1mm (most wires, small tools)

– IP5X: Dust protected (limited ingress, no harmful deposit)

– IP6X: Dust-tight (complete protection against dust ingress)

Second Digit – Liquid Ingress Protection:

– IPX0: No protection against water

– IPX1: Protection against vertically falling drops

– IPX2: Protection against drops up to 15° tilt

– IPX3: Protection against spraying water up to 60° vertical

– IPX4: Protection against splashing water from any direction

– IPX5: Protection against water jets (6.3mm nozzle)

– IPX6: Protection against powerful water jets (12.5mm nozzle)

– IPX7: Protection against temporary immersion (1m depth, 30 minutes)

– IPX8: Protection against continuous immersion (manufacturer-specified depth)

– IPX9: Protection against high-pressure, high-temperature jet spray

IP54 – Basic outdoor protection suitable for covered installation locations. The ‘IP54’ rating provides dust protection (not dust-tight) and splash water protection from any direction. Minimum acceptable rating for string combiner boxes under eaves or other weather protection.

IP65 – Standard outdoor rating for most string combiner box applications. IP65 provides complete dust-tight sealing and protection against low-pressure water jets from any direction. This rating suits typical rooftop and ground-mounted installations in moderate climates.

IP66 – Enhanced water jet protection for high-exposure locations. IP66 maintains dust-tight sealing while withstanding powerful water jets (100 liters/minute at 100 kPa pressure). Appropriate for installations facing direct weather exposure, frequent washing operations, or extreme precipitation environments.

IP67 – Temporary immersion protection for flood-risk locations. IP67 certifies protection during temporary water immersion to 1-meter depth for 30 minutes. Specified for string combiner boxes in flood-prone areas or below-grade installations requiring submersion resistance.

IP ratings require standardized testing per IEC 60529 to verify claimed protection levels. Understanding test methods clarifies practical protection capabilities.

Dust Protection Testing (First Digit 5-6): IP5X testing circulates talcum powder in a sealed chamber with the enclosure under negative pressure for 8 hours. Dust-protected (IP5X) allows limited ingress not affecting operation. Dust-tight (IP6X) prohibits any dust ingress. String combiner boxes should specify IP6X for maximum protection.

Water Jet Testing (Second Digit 5-6): IP65 testing directs 12.5 liters/minute water flow from a 6.3mm nozzle at the enclosure from any angle for 3 minutes minimum. IP66 testing increases to 100 liters/minute from a 12.5mm nozzle. No water ingress causing harmful effects is permitted. Gasket integrity and cable entry sealing determine test passage.

⚠️ Critical Specification: IP ratings do not address corrosion resistance, UV degradation, or temperature cycling performance—coastal installations require explicit corrosion resistance specifications beyond IP rating verification.

String combiner box enclosure material selection directly impacts corrosion resistance, thermal management, mechanical strength, and lifecycle cost. Material specifications must align with environmental exposure and performance requirements.

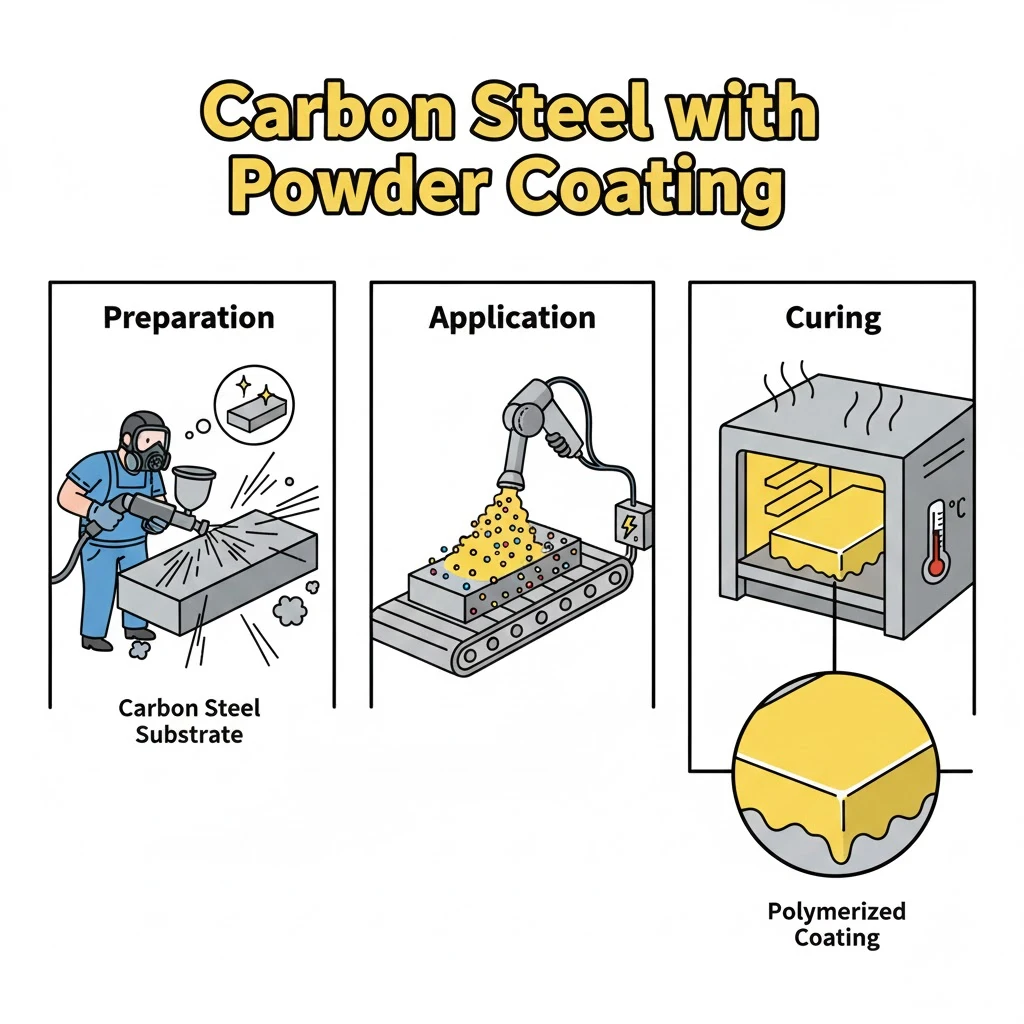

Carbon steel enclosures represent the most economical option for string combiner boxes in non-corrosive environments. Typical specifications include 14-16 gauge cold-rolled steel (1.5-2.0mm thickness) with electrostatically applied polyester or epoxy powder coating.

Performance characteristics: Powder-coated carbon steel provides adequate corrosion resistance in dry, non-coastal environments when coating remains intact. The powder coat thickness typically ranges from 60-100 microns, offering UV resistance and color stability. However, coating damage from installation handling or mechanical impact creates corrosion initiation sites.

Thermal properties: Carbon steel exhibits high thermal conductivity (50 W/m·K), creating potential heat buildup in direct sunlight. Internal temperatures can exceed 70°C in enclosed carbon steel boxes, requiring derating of electrical components. Dark colors absorb more solar radiation, exacerbating thermal issues.

Cost considerations: Carbon steel enclosures cost 40-60% less than stainless steel alternatives, making them attractive for large utility-scale projects with hundreds of combiner boxes. However, coastal installations often experience coating failure within 5-7 years, requiring expensive replacement or refurbishment.

⚠️ Warning: Powder-coated carbon steel enclosures fail rapidly in coastal environments within 5km of saltwater—coating defects accelerate corrosion through galvanic action between steel substrate and coating imperfections.

Stainless steel enclosures provide superior corrosion resistance for demanding environments. Type 304 stainless steel (18% chromium, 8% nickel) suits most installations, while Type 316 (adds 2-3% molybdenum) offers enhanced resistance for severe marine exposure.

Corrosion resistance: Stainless steel’s passive chromium oxide layer provides self-healing corrosion protection. Type 304 withstands normal atmospheric corrosion and industrial environments. Type 316 resists pitting and crevice corrosion in chloride-rich environments, making it mandatory for installations within 1km of oceans or high-salinity areas.

Thermal management: Stainless steel’s lower thermal conductivity (16 W/m·K) compared to carbon steel results in slower heat absorption and more stable internal temperatures. However, polished stainless finishes reflect solar radiation, significantly reducing heat gain. Brushed #4 finish provides optimal balance between aesthetics and thermal performance.

Mechanical properties: 16-gauge (1.5mm) Type 304 stainless steel provides equivalent mechanical strength to 14-gauge carbon steel while reducing weight by 10-15%. The improved strength-to-weight ratio facilitates installation and reduces mounting structure requirements.

Aluminum alloy enclosures combine corrosion resistance with weight reduction. Typical specifications use 5052-H32 aluminum alloy (2.5% magnesium content) in 0.125-0.188 inch (3.2-4.8mm) thickness to achieve structural strength equivalent to thinner steel.

Corrosion characteristics: Aluminum forms a protective aluminum oxide layer providing inherent corrosion resistance. Marine-grade 5052 alloy resists saltwater corrosion without additional coating. However, galvanic corrosion occurs when aluminum contacts dissimilar metals like copper or steel without proper isolation.

Weight advantage: Aluminum weighs approximately 35% of equivalent-strength steel, reducing shipping costs and simplifying installation. A typical 12-string combiner box in aluminum weighs 15-20 kg versus 40-50 kg in steel, eliminating the need for lift equipment.

Thermal performance: Aluminum’s high thermal conductivity (205 W/m·K) would normally increase heat gain, but high emissivity (0.9 for anodized surface) effectively radiates absorbed heat. Anodized aluminum enclosures maintain internal temperatures 8-12°C lower than powder-coated steel under identical conditions.

Non-metallic enclosures manufactured from fiberglass-reinforced polyester (FRP) or polycarbonate provide inherent corrosion immunity and electrical isolation. Fiberglass enclosures suit the most severe corrosive environments while offering competitive pricing.

Chemical resistance: Fiberglass enclosures resist virtually all atmospheric corrosion, including direct acid/alkali exposure. Chemical processing facilities and agricultural operations with corrosive atmospheres benefit from fiberglass’s immunity to chemical attack. UV-stabilized gel coat provides 20+ year exterior durability.

Electrical isolation: Non-conductive enclosure materials eliminate ground faults from enclosure contact, simplifying grounding design. However, external grounding lugs must bond to internal metal components through insulated bushing connections. The electrical isolation prevents stray currents but requires careful bonding design.

Temperature limitations: Polycarbonate enclosures specify maximum operating temperatures of 110-120°C, adequate for most climates. Fiberglass withstands higher temperatures (150°C+) but becomes brittle at temperature extremes. Impact resistance degrades at low temperatures, particularly for polycarbonate below -40°C.

| Matériau | Corrosion Resistance | Weight (Relative) | Cost (Relative) | Meilleure application |

|---|---|---|---|---|

| Carbon Steel Powder Coat | Good (non-coastal) | 1.0× (baseline) | 1.0× (lowest) | Inland installations |

| Stainless Steel 304 | Excellent | 0.9× | 2.5-3.0× | Industrial environments |

| Stainless Steel 316 | Superior (marine) | 0.9× | 3.5-4.0× | Coastal <1km ocean |

| Aluminium 5052 | Very good (marine) | 0.35× | 2.0-2.5× | Weight-critical rooftop |

| Fibre de verre (FRP) | Excellent (chemical) | 0.6× | 1.5-2.0× | Severe corrosion |

String combiner box electrical specifications define voltage and current handling capabilities, component ratings, and protection device coordination. Proper specification ensures safe operation and code compliance.

String combiner boxes must specify maximum continuous DC voltage ratings aligned with PV system design voltage. NEC Article 690.7 requires voltage calculations accounting for temperature effects and module specifications.

1000V DC systems: Residential and small commercial installations typically operate at 600-1000V DC maximum system voltage. String combiner boxes for these systems specify 1000V DC or 1500V DC rated components. The higher voltage rating provides margin for voltage transients and system expansion.

1500V DC systems: Utility-scale and large commercial installations increasingly adopt 1500V DC systems for reduced conductor losses and lower balance-of-system costs. Components must carry UL 1741 or IEC 61730 certification at 1500V DC. Boîte de raccordement PV designs require enhanced insulation coordination and increased creepage/clearance distances.

Voltage withstand testing: String combiner boxes undergo dielectric withstand testing at 2× rated voltage + 1000V for 1 minute per UL 508A standards. A 1000V DC rated combiner must withstand 3000V DC test voltage without breakdown. This verification ensures adequate insulation margins for lightning-induced transients and grid disturbances.

Each string input position specifies maximum continuous current rating based on fuse or Disjoncteur DC sizing. The ratings must accommodate module short-circuit current (I_sc) with appropriate safety factors.

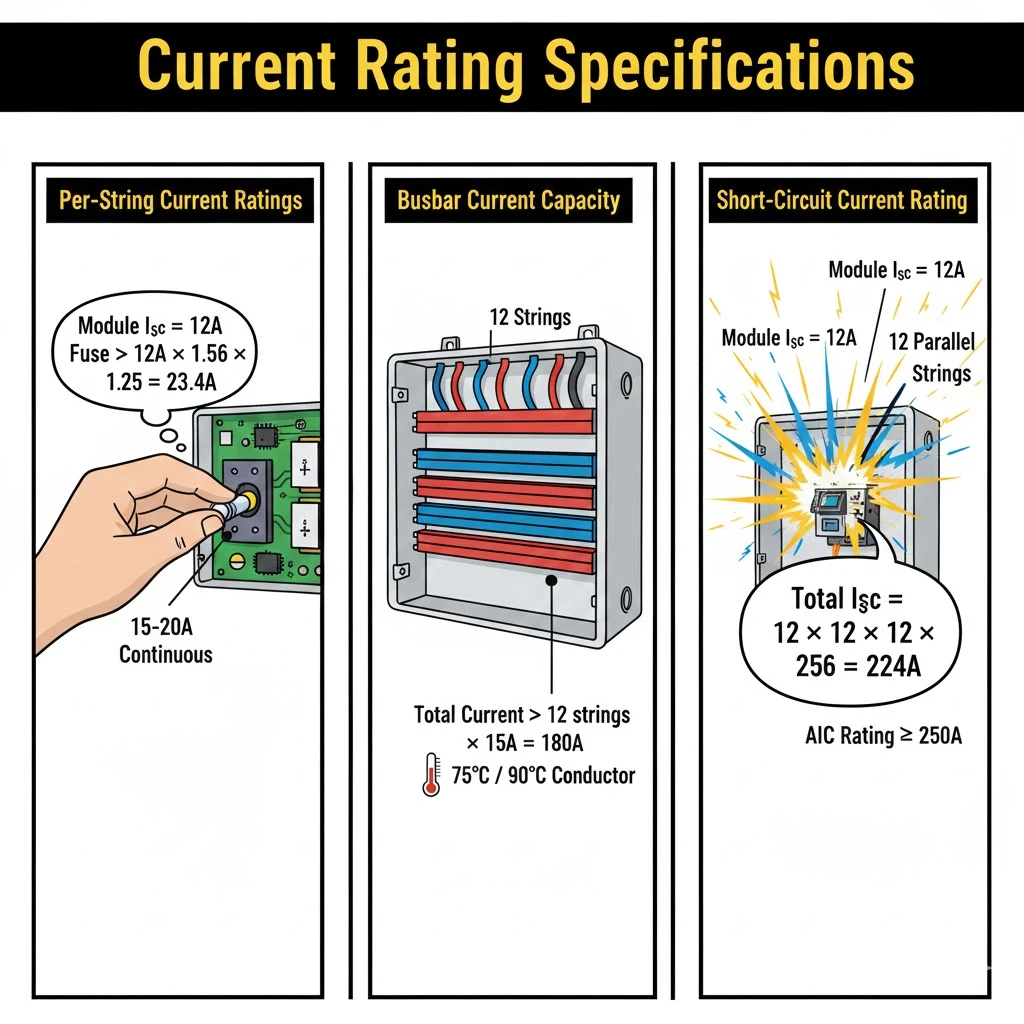

Per-string current ratings: Typical string input positions rate for 10-20A continuous current, matching standard fuse ratings. NEC 690.8 requires fusing at 156% of module I_sc × temperature correction factor. For modules with I_sc = 12A, minimum fuse rating = 12A × 1.56 × 1.25 = 23.4A, requiring 25A or 30A fuses.

Busbar current capacity: Main positive and negative busbars must handle combined current from all parallel strings. A 12-string combiner with 15A per string requires busbar rated for minimum 180A continuous. Busbar sizing follows NEC 110.14(C) termination temperature ratings, typically specifying 75°C or 90°C conductor ratings.

Short-circuit current rating: String combiner boxes specify available fault current (AIC rating) they can safely interrupt. Calculated per NEC 690.8(B)(1), source circuit maximum current = module I_sc × 1.56. A system with 12 parallel strings each producing 12A I_sc: Total I_sc = 12 × 12 × 1.56 = 224A. Specify fuses or breakers with interrupting capacity ≥250A.

All electrical specifications assume operation at specific temperatures, typically 25-40°C ambient. String combiner boxes installed in direct sunlight experience elevated internal temperatures requiring component derating.

Internal temperature rise: Enclosed metal boxes in direct sunlight reach internal temperatures 20-40°C above ambient. At 40°C ambient, internal temperatures exceed 60-80°C. Components rated for 40°C ambient require derating when operating at 70°C+.

Ampacity derating: NEC Table 690.31(C) provides temperature correction factors. At 61-70°C, conductors derate to 0.58× capacity (70°C rating) or 0.71× (90°C rating). A 30A fuse at 40°C derates to 17.4A at 70°C using 70°C rating, inadequate for 25A string current. This necessitates 90°C rated components or oversizing.

Thermal management solutions: Combiner boxes incorporate ventilation slots, heat sinks, or active cooling to manage internal temperatures. Ventilated enclosures maintain IP54/NEMA 3R ratings (not watertight) but reduce temperature rise by 15-20°C. Passive cooling fins on busbar sections dissipate heat through enclosure walls.

String combiner box physical configuration encompasses internal component arrangement, busbar design, terminal accessibility, and mounting provisions. Proper configuration ensures efficient installation, maintenance accessibility, and long-term reliability.

String input terminal arrangement: Individual string inputs typically arrange vertically with fuse holders or breaker positions spaced 50-75mm apart vertically. This spacing accommodates fuse removal tools and allows visual inspection of all positions. Some designs use horizontal arrangement for wide-format enclosures, suitable for wall mounting where vertical space is limited.

Positive and negative busbar routing: Main busbars run horizontally across the enclosure width, connecting all string input terminals. Positive busbar typically mounts on top, negative on bottom, with minimum 50mm separation for 1000V systems (100mm for 1500V systems) per NEC 110.26 working clearance requirements. Busbar insulation or barriers prevent accidental contact.

Output connection location: Combined DC output terminals locate at the enclosure side or bottom for cable exit. Large lugs (typically 4-8 AWG range) accommodate main feeder cables. Compression-style terminals provide superior connection integrity compared to set-screw types, especially for aluminum conductors.

Sélection des matériaux: Copper busbars offer superior conductivity (58 MS/m) compared to aluminum (37 MS/m), allowing smaller cross-sections. Tin-plated copper prevents oxidation at terminal interfaces. Aluminum busbars cost less but require larger cross-sections and special anti-oxidation compounds at connections.

Cross-sectional sizing: Busbar cross-section follows ampacity calculations from NEC 310.15. A 200A continuous busbar at 40°C using copper requires minimum 10mm × 3mm cross-section (30 mm²) at 75°C rating. Aluminum requires 1.6× cross-section (48 mm²) for equivalent ampacity. Verify temperature rise under worst-case solar loading.

Mechanical mounting: Busbars mount to insulated standoffs using M6 or M8 hardware. Standoff spacing (typically 150-200mm) prevents busbar sag under thermal expansion. High-strength porcelain or thermoplastic insulators withstand the mechanical stress while maintaining electrical isolation. Torque specifications (typically 8-12 N·m) ensure secure connections without damaging insulator threads.

String input terminals: Each string position uses screw-clamp or spring-clamp terminals rated for conductor size. Typical specifications accept 10-14 AWG conductors with M4 or M6 screws. Spring-clamp terminals provide tool-free connection and vibration resistance but cost 50-100% more than screw-clamp types.

Torque requirements: Screw terminals specify torque values (typically 1.5-2.5 N·m for 12 AWG) preventing under-tightening (high resistance) or over-tightening (conductor damage). Torque-limited screwdrivers or torque wrenches ensure proper installation. Quality terminal blocks include torque indicators showing proper tightening.

Terminal material compatibility: Copper conductors connect to brass or tin-plated copper terminals without issues. Aluminum conductors require anti-oxidation compound and terminals specifically rated for aluminum connections. Mixed copper-aluminum connections create galvanic corrosion requiring bimetallic transition connectors.

🎯 Conseil de pro: Specify string combiner boxes with color-coded busbar insulation (red for positive, black for negative) and laser-engraved terminal numbering—these features reduce installation errors and accelerate troubleshooting during maintenance.

Fuse-based protection: Traditional string combiner boxes use DC-rated fuses in touch-safe fuse holders. Fuses provide reliable overcurrent protection at low cost ($5-15 per position) but lack load-breaking capability. Fuse replacement after fault events costs $10-30 in materials plus service call labor.

Circuit breaker protection: Modern designs integrate miniature DC circuit breakers (1-2P, 10-20A rating) offering load-breaking capability and reusable protection. Initial cost ($40-80 per position) exceeds fuses but eliminates replacement costs. Breakers enable individual string isolation for maintenance without de-energizing adjacent strings.

Hybrid configurations: Some combiner boxes provide fuse protection with additional DC switch disconnectors for load-breaking capability. This approach combines fuse cost-effectiveness with breaker operational convenience. The disconnector upstream of fuses enables safe fuse replacement under load conditions.

Basic monitoring: Entry-level monitoring uses Hall-effect current sensors on the main busbar measuring combined string current. Single-point monitoring detects gross system faults but cannot identify individual string issues. Cost-effective for residential systems where string-level monitoring provides minimal value.

String-level monitoring: Advanced combiner boxes integrate current sensors on each string input, measuring individual string current with ±2% accuracy. This enables remote fault detection, performance comparison, and predictive maintenance. String monitoring adds $50-150 per string position but dramatically reduces troubleshooting time.

Communication interfaces: Modern smart combiners incorporate Ethernet, RS485, or wireless communication modules transmitting data to monitoring platforms. Modbus RTU/TCP protocols enable integration with existing building management or SCADA systems. Cloud-connected combiners provide smartphone app access to real-time data and alerts.

Many string combiner boxes include provisions for SPD (surge protective device) installation protecting against lightning-induced transients. SPD mounting locations allow short ground lead connections minimizing inductance. Dedicated SPD models integrate Type 2 surge arresters directly in the combiner design.

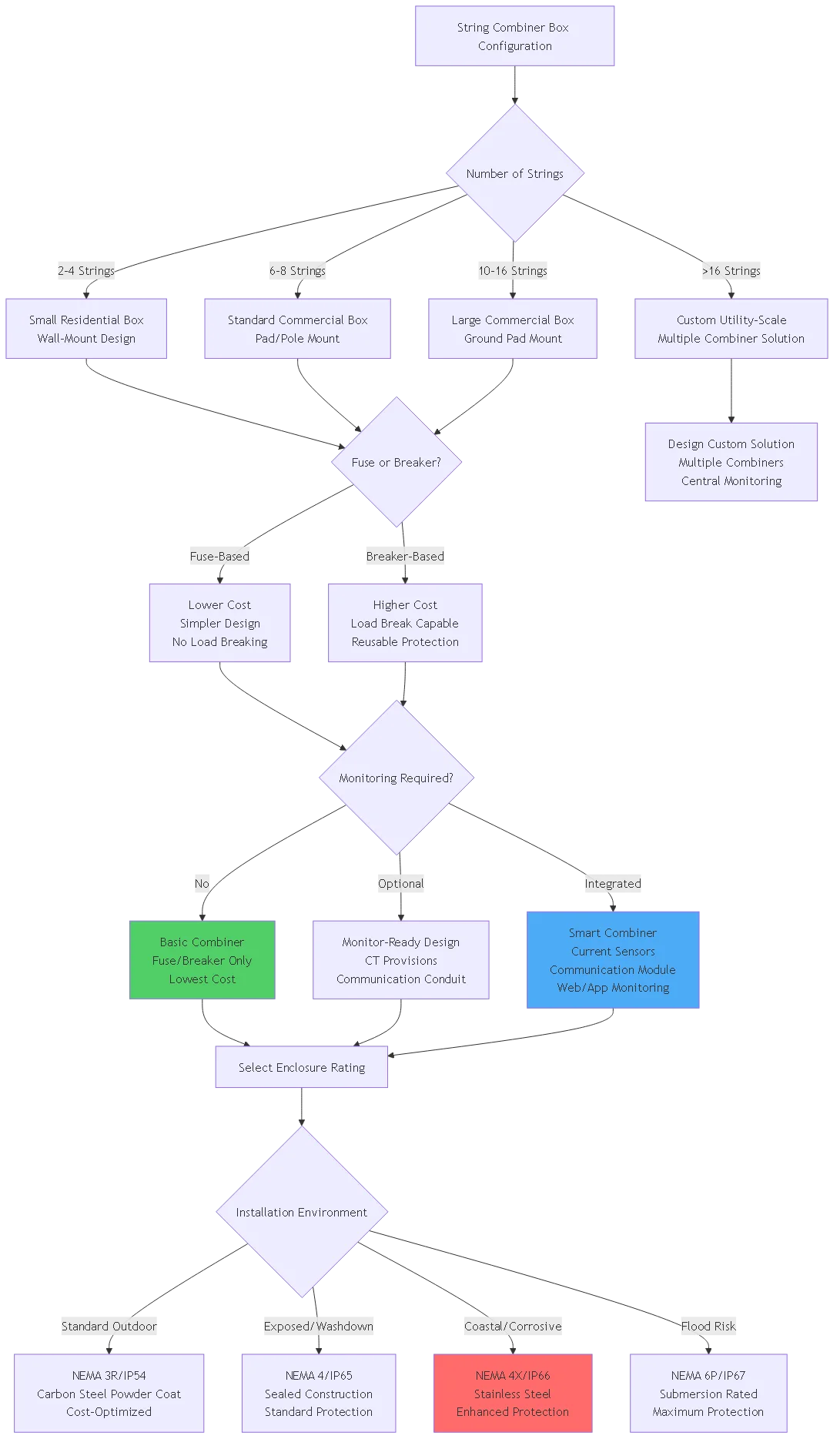

Systematic string combiner box selection follows a structured methodology evaluating environmental requirements, electrical parameters, physical constraints, and feature priorities.

Evaluate installation location environmental factors determining enclosure rating requirements. Consider coastal proximity, pollution exposure, washdown operations, flood risk, and temperature extremes. Coastal locations within 5km of salt water mandate NEMA Type 4X or IP66 with stainless steel/fiberglass construction. Industrial environments with chemical exposure require corrosion-resistant materials. Flood-prone areas need NEMA Type 6P or IP67 submersion protection.

Calculate required voltage and current ratings from PV system design parameters. Determine maximum system voltage from string configuration and module specifications with temperature correction. Calculate required string current capacity from module I_sc × 1.56 × 1.25 safety factor. Determine total busbar capacity from parallel string count multiplied by string current. Verify available fault current for interrupting rating specification.

Determine optimal combiner box size and string capacity from array layout. Count parallel strings requiring combination and specify appropriate combiner capacity with 20% spare positions for future expansion. Evaluate mounting requirements (wall, pole, pad-mount) based on installation constraints. Consider maintenance accessibility for fuse replacement or troubleshooting operations.

Decide on fuse versus circuit breaker protection based on budget, operational requirements, and maintenance philosophy. Evaluate monitoring requirements—basic, string-level, or smart connectivity. Determine if integrated SPD protection justifies additional cost. Consider future functionality like arc fault detection or rapid shutdown provisions.

Compare total cost of ownership across enclosure material and feature options. While stainless steel costs 2.5-4× more initially than powder-coated steel, coastal environments may require replacement every 5-7 years. Twenty-year lifecycle cost analysis often favors stainless steel for corrosive environments despite higher initial investment. Similarly, string-level monitoring adds upfront cost but reduces troubleshooting labor expenses.

| Critères de sélection | Residential (2-6 strings) | Commercial (8-12 strings) | Utility (16+ strings) |

|---|---|---|---|

| Typical Voltage Rating | 600-1000V DC | 1000V DC | 1500V DC |

| Per-String Current | 10-15A | 15-20A | 15-25A |

| Enclosure Rating | NEMA 3R/IP54 | NEMA 4/IP65 | NEMA 4X/IP66 |

| Material Preference | Powder-coated steel | Aluminum/SS 304 | SS 316/Fiberglass |

| Protection Type | Fuse-based | Breaker or fuse | Breaker preferred |

| Monitoring Level | Optional | String-level | Integrated SCADA |

Problème: Specifying NEMA Type 3R (rain-tight only) enclosures for exposed coastal locations results in rapid corrosion failure. Type 3R provides minimal dust protection and no corrosion resistance, inadequate for harsh environments.

Common scenarios: Installing powder-coated steel NEMA 3R boxes within 5km of oceans, in industrial areas with chemical exposure, or locations with frequent high-pressure washing operations. The enclosures corrode through coating defects within 2-5 years.

Correction: Coastal installations within 5km of saltwater require NEMA Type 4X with stainless steel 316 construction or fiberglass materials. Industrial environments need IP66 rating with chemical-resistant materials. Specify appropriate environmental protection matching actual site conditions through proper site assessment.

Problème: Selecting combiner boxes with voltage ratings insufficient for temperature-corrected Voc calculations violates NEC 690.7 and creates safety hazards during cold weather operation when module voltage peaks.

Common scenarios: Specifying 1000V DC rated components for systems with temperature-corrected Voc exceeding 950V, failing to account for series string additions during system expansion, undersizing busbar current capacity for all parallel strings.

Correction: Calculate maximum system voltage using: Voc_STC × (1 + α_V × ΔT) where ΔT accounts for minimum ambient temperature (-40°C typical). Specify combiner voltage rating ≥1.25× calculated maximum. Size busbar current for sum of all string currents: N_strings × I_sc × 1.56 × 1.25, with 20% margin for future expansion.

Problème: Failing to derate electrical components for elevated internal temperatures in enclosed combiner boxes results in nuisance fuse failures or component degradation. Direct sunlight exposure creates 60-80°C internal temperatures requiring significant capacity derating.

Common scenarios: Selecting 75°C rated terminals operating at 70°C internal temperature with only 58% ampacity, specifying 30A fuses adequate at 40°C but insufficient at 70°C operating temperature, using wire sizes calculated for 30°C ambient without temperature correction.

Correction: Specify 90°C rated components for elevated temperature operation. Apply NEC 310.15(B)(2) temperature correction factors to all current-carrying components. Consider ventilated enclosure designs or reflective coatings reducing internal temperature rise. Measure actual operating temperatures during commissioning to verify adequate derating.

Problème: Using aluminum enclosures in contact with copper busbars without proper isolation creates galvanic corrosion destroying connections within 5-10 years. Dissimilar metal contact in presence of moisture accelerates electrochemical corrosion.

Common scenarios: Mounting copper busbars directly to aluminum enclosure walls using steel hardware, connecting aluminum and copper conductors without anti-oxidation compounds, using carbon steel hardware in stainless steel enclosures without isolation.

Correction: Isolate dissimilar metals using nonconductive barriers, insulating washers, or compatible transition connectors. Apply anti-oxidation compound to all aluminum-copper interfaces. Use stainless steel hardware matching enclosure material (304 hardware with 304 enclosure). Verify galvanic compatibility of all material combinations per ASTM G82 galvanic series guidelines.

⚠️ Critique: Never install aluminum combiner boxes using carbon steel mounting hardware in coastal environments—galvanic corrosion between aluminum enclosure and steel bolts causes structural failure within 3-5 years of exposure.

NEMA Type 4 and Type 4X provide identical protection against water and dust ingress, but Type 4X adds explicit corrosion resistance requirements through material specifications. Type 4 enclosures may use carbon steel with powder coating or galvanizing, adequate for non-corrosive environments but susceptible to coating degradation in harsh atmospheres. Type 4X mandates stainless steel (typically 304 or 316 grade), fiberglass, or other inherently corrosion-resistant materials that maintain integrity without protective coatings. The practical difference appears in lifecycle cost—Type 4 enclosures cost 40-50% less initially but may require replacement within 5-7 years in coastal or industrial environments, while Type 4X enclosures provide 20+ year service life in these same conditions. For string combiner box installations within 5km of oceans, chemical plants, or areas with significant atmospheric corrosivity, specify Type 4X despite higher initial cost to avoid premature failure and costly replacement.

IP65 and IP66 differ in water jet protection level—IP65 withstands low-pressure jets (12.5 liters/minute from 6.3mm nozzle) while IP66 resists powerful jets (100 liters/minute from 12.5mm nozzle). For string combiner box installations, specify IP65 for typical rooftop or ground-mounted locations where exposure consists of normal rainfall and occasional cleaning with garden hose pressure. Upgrade to IP66 for installations facing direct exposure to severe weather, frequent high-pressure washdown operations (common in agricultural or food processing facilities), or locations requiring regular cleaning to maintain cooling performance. Coastal installations with salt spray exposure benefit from IP66 to ensure moisture doesn’t penetrate during wind-driven rain events. Both ratings provide equivalent dust protection (IP6X – dust-tight), so the decision hinges purely on anticipated water pressure exposure. Consider that IP66 enclosures cost 15-25% more than IP65 due to enhanced gasket systems and more robust latching mechanisms required to maintain seal integrity under high-pressure water jets.

Verify five critical electrical specifications when selecting string combiner boxes. First, maximum DC voltage rating must equal or exceed your system’s temperature-corrected open-circuit voltage: Voc_max = Voc_STC × (1 + temperature coefficient × ΔT), typically requiring 1000V or 1500V rating with 25% margin. Second, per-string current capacity must accommodate module short-circuit current with safety factors: I_string = I_sc × 1.56 × 1.25 per NEC 690.8, typically requiring 15-30A fuse or breaker ratings. Third, busbar ampacity must handle combined current from all parallel strings with 20% expansion margin: I_busbar = N_strings × I_string × 1.2, verified at elevated operating temperature using NEC 310.15 derating factors. Fourth, short-circuit current rating (AIC or I_sc) of protection devices must exceed available fault current from parallel string contribution: Total I_sc = N_strings × module I_sc × 1.56. Fifth, verify all component temperature ratings account for internal enclosure temperatures which may reach 60-80°C in direct sunlight—specify 90°C rated terminals and conductors to ensure adequate derating. Request manufacturer certification documenting these ratings per UL 508A or IEC 61439 standards.

Choose between fuse-based and circuit breaker-based string combiner boxes based on operational priorities and lifecycle cost analysis. Fuse-based combiners cost 60-70% less initially ($5-15 per string position versus $40-80 for breakers) and provide reliable overcurrent protection with high interrupting capacity. However, fuses lack load-breaking capability, requiring separate disconnect switches for safe maintenance, and must be replaced after fault events at $10-30 per fuse plus service labor. Circuit breaker-based combiners offer load-breaking capability enabling individual string isolation without system shutdown, reusable protection eliminating replacement costs, and visual indication of tripped positions simplifying troubleshooting. For residential installations with 2-6 strings accessed infrequently, fuse-based designs prove most cost-effective. Commercial systems with 8-12 strings benefit from breaker convenience justifying higher initial cost through reduced maintenance expenses. Utility-scale installations with 16+ strings require breakers for operational flexibility enabling string maintenance during production hours. Consider hybrid designs combining fuses for overcurrent protection with upstream load-break disconnectors providing both cost optimization and operational convenience.

Coastal installations within 5km of saltwater require explicit corrosion-resistant material specifications beyond standard NEMA or IP ratings. For locations 1-5km from ocean, specify minimum Type 304 stainless steel (18% chromium, 8% nickel) or marine-grade aluminum alloy 5052 with anodized finish—both materials resist atmospheric salt spray and maintain structural integrity for 15-20 years. For installations within 1km of breaking waves or in salt spray zones, mandate Type 316 stainless steel (adds 2-3% molybdenum for enhanced pitting resistance) or fiberglass-reinforced polyester providing immunity to chloride corrosion. Verify material specifications include ASTM B117 salt spray testing certification with minimum 1000-hour exposure without degradation. Prohibit carbon steel enclosures regardless of coating quality—powder coat defects from installation handling create galvanic corrosion cells accelerating failure. All mounting hardware, hinges, and latches must match enclosure material (316 SS hardware with 316 enclosure) to prevent galvanic corrosion between dissimilar metals. Specify additional protective measures including conformal coating on internal electronics and anti-corrosion gel on all terminations to maximize service life in harsh marine environments.

Monitoring capability specification depends on system size and operational requirements. For residential systems under 15 kW with 2-6 strings, basic monitoring using single current sensor on main busbar provides adequate fault detection at minimal cost ($50-100 addition)—this identifies gross system failures without pinpointing individual string issues. Commercial systems 15-100 kW with 8-12 strings benefit from string-level monitoring measuring individual string current with ±2% accuracy ($50-150 per string additional cost)—this enables remote fault identification, performance comparison between strings, and predictive maintenance by detecting gradual degradation patterns. Utility-scale systems exceeding 100 kW should specify integrated monitoring with embedded communication (Ethernet, RS485, or cellular) providing real-time data logging, cloud connectivity, and automated alert generation ($300-600 per combiner)—the investment reduces troubleshooting costs and downtime through proactive fault detection. Verify monitoring systems support industry-standard protocols (Modbus RTU/TCP, SunSpec) enabling integration with existing SCADA or building management systems. Consider future expansion by specifying monitor-ready designs with current transformer mounting provisions and communication conduit even if not immediately equipped—retrofit costs typically exceed 3× initial installation costs due to field modification labor.

Matching string combiner box specifications to NEC Article 690 requirements involves systematic verification of multiple code sections. NEC 690.7 mandates voltage ratings account for lowest expected temperature using: Maximum voltage = Voc at lowest temp × 1.25 correction factor for crystalline modules—verify combiner voltage rating exceeds this calculated value. NEC 690.8 requires overcurrent protection at 156% of module Isc with additional 125% safety factor for continuous operation: Required protection rating = Isc × 1.56 × 1.25—verify fuse or breaker ratings meet or exceed this calculated minimum. NEC 690.9 specifies ground fault protection for systems exceeding 50V to ground requiring isolation monitoring or ground fault detection integration—verify combiner design accommodates required sensors without compromising insulation resistance. NEC 690.15 mandates readily accessible disconnecting means for DC circuits—specify combiners with circuit breakers or add separate disconnect switches upstream of fuse-based designs. NEC 690.31 requires identification of DC conductors and specifies torque requirements for terminations—verify combiner includes labeled terminals and torque specifications meeting this requirement. NEC 110.14(C) restricts terminal temperature ratings and conductor sizing—verify all combiner terminals rated 75°C minimum (90°C preferred) and busbar sizing accounts for temperature derating per NEC 310.15(B)(2). Request manufacturer documentation demonstrating UL 508A listing and compliance with NEC requirements.

Proper string combiner box specification requires systematic evaluation of environmental protection ratings, electrical parameters, physical configuration, and component integration options to ensure optimal equipment selection matching application requirements. Understanding the distinctions between NEMA and IP rating systems, material corrosion resistance characteristics, and electrical specification methodology enables informed purchasing decisions balancing initial cost against lifecycle performance.

Principaux enseignements :

1. NEMA and IP rating equivalency provides approximate correlation (NEMA 3R ≈ IP54, NEMA 4 ≈ IP65, NEMA 4X ≈ IP66) but NEMA includes corrosion and ice formation criteria absent from IP codes.

2. Sélection des matériaux dramatically impacts lifecycle cost in corrosive environments—stainless steel costs 2.5-4× more initially than powder-coated steel but provides 20+ year service life versus 5-7 years in coastal locations.

3. Electrical specifications must account for temperature-corrected voltage calculations, proper current derating factors, and adequate interrupting capacity to ensure safe operation and code compliance.

4. Physical configuration choices between fuse and breaker protection, monitoring integration levels, and component layout significantly affect operational convenience and long-term maintenance costs.

5. Systematic selection methodology following structured evaluation of environmental, electrical, physical, and feature requirements ensures optimal string combiner box specification for diverse PV applications.

Related Resources:

– PV Combiner Box Design and Installation

– DC Fuse Selection for String Protection

– DC Circuit Breaker Integration

Ready to specify the optimal string combiner box for your PV installation? Contact SYNODE’s technical team for application-specific recommendations based on your environmental conditions, electrical system parameters, and operational requirements. We provide detailed specification analysis, material selection guidance, and code compliance verification ensuring proper combiner box selection for residential, commercial, and utility-scale solar projects worldwide.

Dernière mise à jour : Octobre 2025

Auteur : L'équipe technique de SYNODE

Révisé par : Département de génie électrique