Dirección

304 North Cardinal

Dorchester Center, MA 02124

Horas de trabajo

De lunes a viernes: de 7.00 a 19.00 horas

Fin de semana: 10.00 A 17.00 HORAS

Dirección

304 North Cardinal

Dorchester Center, MA 02124

Horas de trabajo

De lunes a viernes: de 7.00 a 19.00 horas

Fin de semana: 10.00 A 17.00 HORAS

Ever wondered why some solar installations run seamlessly for decades while others face costly downtime or even fires? The answer often lies in a component many overlook: the PV solar Combiner Box (PCB). As the “traffic hub” of solar arrays, it consolidates high-voltage DC power, protects against electrical faults, and ensures regulatory compliance—making it indispensable for long-term reliability. For solar EPCs, developers, and maintenance teams, understanding the PCB’s role isn’t just technical—it’s key to maximizing ROI.

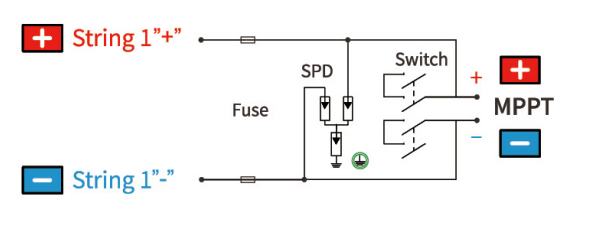

A PV solar Combiner Box is an electrical enclosure that acts as the central nexus for solar panel strings. Its core job? Consolidate DC output from multiple PV strings into a single high-capacity circuit before sending power to the inverter. This reduces wiring complexity (critical for large-scale farms) and serves as the first line of defense for the DC side of solar systems—per electrical codes like those outlined by the National Electrical Code (NEC) y IEC standards.

For example, a 1MW solar farm with 50 PV strings would rely on a PCB to merge those 50 separate DC feeds into just two wires (positive/negative) leading to the inverter. Without it, wiring costs and failure points would skyrocket.

Here’s the harsh truth: Many view PCBs as “standard parts,” but their design and component quality directly dictate system safety and profitability. A poorly specified PCB (e.g., undersized fuses or low-voltage components) can cause:

At SinoBreaker, we prioritize PCB component quality—from Disyuntores de CC to surge protectors—to avoid these risks.

Inside every PCB, a copper busbar (a flat metal strip) acts as the “meeting point” for PV strings. It connects the positive/negative wires of 5–20 strings (depending on system size) to a single output pair, streamlining power flow. This design:

For reference, a utility-scale solar farm with 10,000 panels could save $50,000+ in wiring costs by using PCBs— a benefit that scales with project size.

PCBs are non-negotiable for:

SinoBreaker offers customizable PCBs tailored to your project’s voltage (1000V/1500V) and environmental needs—learn more about our custom solar solutions.

A PCB’s value lies in its protective components. Below is a breakdown of what keeps your solar system safe:

| Component Type | Primary Function | Mode of Operation | Use Case | SinoBreaker Link |

|---|---|---|---|---|

| Disyuntor de CC | Stop surge/overvoltage faults | Automatic | Protect the entire combined DC circuit | DC Circuit Breakers |

| Fusible CC | Block reverse current (string-level protection) | Single-use (burns out) | Shield individual PV strings from shading/damage | Fusibles CC |

| DC Isolator Switch | Safe manual disconnection for maintenance | Manual | Isolate power during inspections | DC Isolators |

| Surge Protection Device (SPD) | Divert lightning/switching spikes to ground | Automatic (sacrificial) | Protect inverters/panels from transients | Solar SPDs |

Reverse current is a silent killer: When a shaded/damaged PV string is connected to a healthy one, current flows backward, causing hot spots and panel degradation. Fusibles CC (sized to ~1.25x the string’s short-circuit current) block this— but only if they’re correctly rated.

Oversized fuses? They won’t trip during faults, damaging inverters. Undersized? Nuisance tripping shuts down the system unnecessarily. SinoBreaker’s fuses are pre-sized for 1000V/1500V systems, eliminating guesswork.

Lightning strikes or electrical switching can cause voltage spikes (up to 10x the system’s rated voltage) that fry inverters. SPDs in the PCB divert these spikes to ground— but they’re sacrificial (they degrade after use).

Pro tip: Test SPDs quarterly. A failed SPD leaves your inverter exposed— replace it immediately with a SinoBreaker solar SPD to avoid costly repairs.

DC power has no “zero-crossing” (unlike AC), making arcs harder to extinguish. This is why PCBs need specialized components:

Shading, soiling, or panel degradation causes “string mismatch”—where one string produces less power than others. PCBs solve this by connecting strings in parallel:

The next generation of PCBs is “intelligent”: They integrate DC-DC converters and real-time monitoring to:

SinoBreaker’s smart combiner boxes sync with SCADA systems via RS485 MODBUS—learn how they reduce maintenance costs by 30% here.

Loose terminals (from thermal cycling) or moisture ingress (from cracked enclosures) are the top causes of PCB failures. A single loose wire can generate enough heat to start an arc fault—costing $10,000+ in repairs and lost revenue.

Always isolate power before working on a PCB. Use this checklist (adapted from IEC 62446):

| Inspection Area | Action | Acceptable Threshold |

|---|---|---|

| Recinto | Check for rust, cracks, or water damage | No damage; IP65/NEMA rating intact |

| Terminals | Tighten loose connections; check corrosion | No corrosion; torque to manufacturer specs |

| Fuses/breakers | Verify ratings; replace blown fuses | Match design (e.g., 15A for 10A string) |

| Insulation resistance | Test with a megohmmeter | >2 megohms (busbar to ground) |

| SPDs | Test functionality | No degradation (replace if faulty) |

For a detailed guide, download SinoBreaker’s PV Combiner Box Maintenance Manual.

The PV combiner box isn’t just a wiring junction—it’s the guardian of your solar system’s safety, efficiency, and profitability. Cutting costs on PCBs leads to higher long-term expenses (repairs, downtime, fines). Instead:

Ready to upgrade your solar system’s reliability? Contact our team to discuss custom PV combiner boxes or browse our solar protection products.