Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

A 6 string PV combiner box represents the transition from residential to commercial-scale solar installations. While 2-4 string configurations serve most residential needs, commercial projects require robust engineering to handle higher currents and meet industrial environment standards.

Designing a 6 string combiner box involves critical calculations for busbar capacity, proper component derating, and selecting enclosures that withstand decades of outdoor exposure. This guide provides the engineering fundamentals commercial installers need for 50-200kW system designs.

💡 Commercial Scale Reality: 6 string combiner boxes typically handle 60-80A of combined current, requiring copper busbars rated 125A minimum with proper temperature derating applied per NEC 690.8(B).

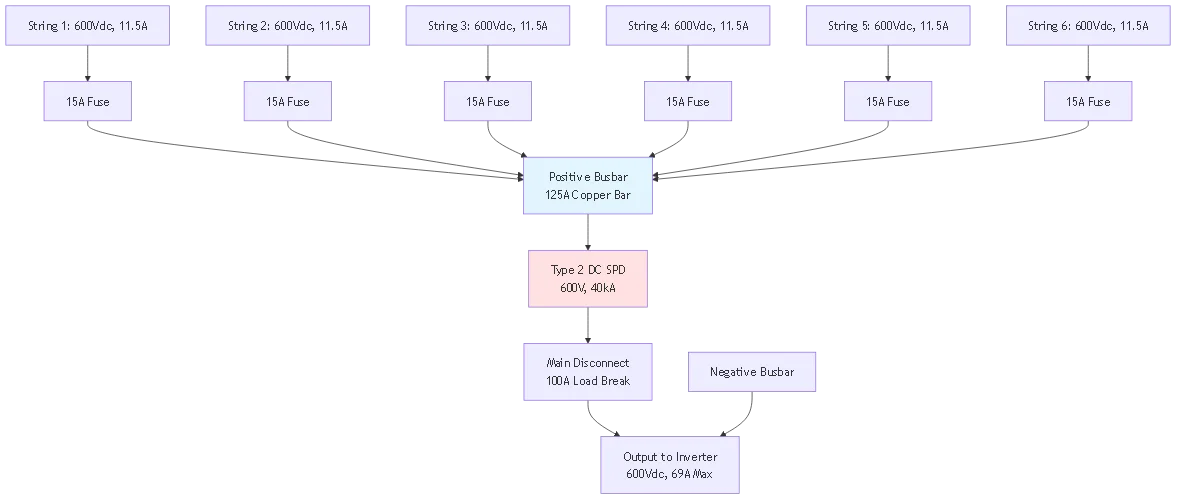

A 6 string PV combiner box consolidates output from six parallel photovoltaic strings into a single DC circuit feeding the inverter or main distribution system. This configuration is standard for commercial rooftop installations ranging from 50kW to 200kW.

Typical 6-String System Profile:

– String voltage: 600-1000Vdc (15-25 modules per string)

– String current: 9-12A per string (400-550W modules)

– Combined current: 54-72A at maximum power point

– System capacity: 50-150kW depending on module wattage

– Applicazione: Small commercial, industrial rooftops, carports

A properly engineered 6 string combiner box includes:

1. Input protection: Six fused or breaker-protected inputs (one per string)

2. Main busbar: Copper bar rated 125A minimum (125% of max combined current)

3. Output protection: Main disconnect or breaker (80-100A typical)

4. Surge protection: Type 2 DC SPD rated for system voltage

5. Involucro: NEMA 3R minimum, NEMA 4X for coastal environments

6. Monitoring: Optional string current monitoring on each input

Commercial Difference: Unlike residential 2-4 string boxes, 6 string configurations require engineered busbar layouts to prevent voltage drop and ensure proper fault clearing.

Commercial 6 string systems typically use one of three architectures:

Architecture 1: Single Combiner to Central Inverter

– Six strings → one combiner box → single 50-150kW inverter

– Most common for compact commercial rooftops

– Shortest DC cable runs, lowest installation cost

– Single point of failure risk

Architecture 2: Multiple Combiners with Parallel Feeds

– 2× combiner boxes (3 strings each) → parallel DC feeds → inverter

– Used when strings are physically separated on roof

– Improved redundancy, easier troubleshooting

– Higher material cost, more complex wiring

Architecture 3: Combiner with String Optimizers

– Six strings with optimizers → combiner → inverter DC input

– Maximum energy harvest, module-level monitoring

– Highest system cost, best performance in shading

– Required for rapid shutdown in some jurisdictions

🎯 Suggerimento professionale: For rooftops with multiple orientations or partial shading, architecture 3 with string optimizers provides 5-15% higher annual energy yield despite the premium cost.

Step 1: Calculate Maximum Combined String Current

Per NEC 690.8(A), the maximum circuit current is:

I_max = 1.25 × (Number of Strings × I_sc)

Example Calculation:

– Module I_sc: 11.5A

– Number of strings: 6

– I_max = 1.25 × (6 × 11.5A) = 86.25A

Step 2: Select Busbar Rating

Busbar must be rated ≥125% of I_max (per NEC 690.8(B)):

Busbar rating = 1.25 × 86.25A = 107.8A

Select: 125A copper busbar (standard commercial size)

| Materiale | Conducibilità | Current Capacity (100mm²) | Applicazione |

|---|---|---|---|

| Copper (C110) | 100% IACS | 175A @ 30°C | Standard commercial, best performance |

| Tin-Plated Copper | 98% IACS | 172A @ 30°C | Coastal, corrosion resistance |

| Aluminum (6061-T6) | 61% IACS | 135A @ 30°C | Large utility systems, weight reduction |

| Silver-Plated Copper | 105% IACS | 180A @ 30°C | High-temperature applications, premium |

Commercial Recommendation: Tin-plated copper busbars provide optimal balance of conductivity, corrosion resistance, and cost for 6 string combiner boxes in most environments.

Busbar capacity must be derated for ambient temperature per NEC 310.15(B)(2)(a):

Fattori di declassamento:

– 30°C ambient: 1.00 (no derating)

– 40°C ambient: 0.91 (desert, summer rooftops)

– 50°C ambient: 0.82 (inside enclosures, direct sun)

– 60°C ambient: 0.71 (worst-case scenario)

Esempio:

– 125A busbar @ 30°C base rating

– 50°C ambient (typical rooftop enclosure)

– Derated capacity = 125A × 0.82 = 102.5A

– Still adequate for 86.25A max current ✅

⚠️ Critico: Black NEMA enclosures in direct sun can reach 60°C+ internal temperatures. Use white/gray enclosures or add sunshields to maintain ≤50°C ambient for proper busbar performance.

Commercial 6 string combiner boxes require more robust enclosures than residential systems due to higher internal heat generation and longer service life expectations.

NEMA 3R (Standard Commercial)

– Indoor or outdoor use with protection from rain/sleet/snow

– Not dust-tight or corrosion-resistant

– Adequate for most temperate climates

– Lowest cost option (~$250-400 for 6-string size)

NEMA 4X (Premium Commercial)

– Fully weatherproof and corrosion-resistant

– Stainless steel (304/316) or fiberglass construction

– Required for coastal, industrial, or chemical environments

– Higher cost (~$600-1200) but 25+ year lifespan

NEMA 12 (Indoor Industrial)

– Dust-tight and drip-tight for indoor installations

– Not suitable for outdoor use

– Used for garage/warehouse mounted combiners

– Mid-range cost (~$350-600)

Minimum Internal Volume Formula:

Volume (cubic inches) = (Number of components × Component volume) × 1.5

6 String Example:

– 6× string fuse holders: 6 × 8 in³ = 48 in³

– 1× main disconnect: 60 in³

– 1× DC SPD: 25 in³

– Busbar system: 40 in³

– Total = 173 in³ × 1.5 margin = 260 in³ minimum

Standard Enclosure Sizes:

– 16″ × 14″ × 6″ = 1,344 in³ ✅ (typical 6-string size)

– 18″ × 16″ × 8″ = 2,304 in³ (oversized for future expansion)

💡 Engineering Tip: Specify enclosures 50% larger than minimum calculations to allow proper heat dissipation and future component additions. Cramped enclosures reduce service life and complicate maintenance.

For 6 string commercial systems, the choice between fuses and breakers impacts both performance and economics:

Fused Inputs (Recommended for 6-String)

✅ Vantaggi:

– Lower cost ($15-30 per fuse holder vs $80-150 per breaker)

– Faster fault clearing (interrupt in <5ms vs 10-50ms)

- No maintenance required

- Compact installation (6 fuse holders = 12" rail vs 18" for breakers)

❌ Svantaggi:

– Requires spare fuses on-site for quick replacement

– Cannot remote-trip for testing

– No visual indication when blown (requires multimeter)

Il migliore per: Standard commercial rooftop installations with easy access for maintenance

Breaker Inputs (Alternative)

✅ Vantaggi:

– Resettable without replacement parts

– Visual indication of trip status

– Manual disconnect capability per string

– Better for remote/difficult-access sites

❌ Svantaggi:

– 3-5× higher initial cost

– Larger enclosure required

– Periodic maintenance (annual trip testing)

Il migliore per: Remote sites, utility-scale systems, applications requiring frequent string isolation

NEC 690.16 Requirement:

Fuse rating ≤ 1.56 × I_sc of module

Example Calculation:

– Module I_sc: 11.5A

– Maximum fuse rating: 1.56 × 11.5A = 17.94A

– Select: 15A gPV fuse (next lower standard size) ✅

Standard 6-String Fuse Configuration:

– Input fuses: 6× 15A gPV fuses (one per string)

– Main fuse (if used instead of breaker): 80A or 100A based on combined current

– All fuses: Same voltage rating as system (600V, 1000V, or 1500V class)

Commercial combiner boxes require properly coordinated surge protection to prevent lightning-induced overvoltages from damaging the inverter or strings.

SPD Specification Parameters:

1. Voltage Rating (U_c): Must exceed system V_oc

– 600V system → 800V U_c minimum

– 1000V system → 1200V U_c minimum

– Safety margin: 120% of maximum V_oc at -40°C

2. Discharge Current (I_n): Based on exposure risk

– Standard commercial: 20kA (8/20µs)

– High exposure (tall buildings): 40kA (8/20µs)

– Lightning-prone regions: 60kA (8/20µs)

3. Voltage Protection Level (U_p): Maximum let-through voltage

– Must be <80% of inverter DC input rating

- Example: 1000V inverter → U_p ≤ 800V

Installation Requirements:

– Lead length: <0.5m total (positive + negative + ground)

- Wire size: Minimum #6 AWG copper for SPD connections

– Grounding: Direct connection to building ground electrode system

– Location: Between busbar and main disconnect for optimal protection

⚠️ Critico: SPD lead lengths >0.5m significantly reduce protection effectiveness. Mount SPD as close as physically possible to the busbar junction point.

The main disconnect must handle the combined output current with adequate margin for transient conditions:

Sizing Formula:

Main disconnect rating ≥ 1.25 × Maximum combined current

6 String Example:

– Combined I_mp: 6 × 11.5A = 69A

– Minimum disconnect: 1.25 × 69A = 86.25A

– Select: 100A load-break disconnect switch ✅

Load-Break vs Non-Load-Break:

Load-Break Disconnect (Recommended)

– Can interrupt current under load

– Safer for emergency shutdown

– Required per NEC 690.13 for outdoor installations

– Premium cost (+40% vs non-load-break)

Non-Load-Break Disconnect

– Must be opened under no-load conditions only

– Lower cost option

– Acceptable only for indoor installations

– Risk of arc flash if opened under load

Output cables from combiner to inverter must handle maximum current with voltage drop <2%:

Cable Sizing Table (90°C Copper, Conduit):

| Distance to Inverter | 70A Output | 80A Output | 90A Output |

|---|---|---|---|

| 0-50 feet | #6 AWG | #4 AWG | #4 AWG |

| 50-100 feet | #4 AWG | #2 AWG | #1 AWG |

| 100-150 feet | #2 AWG | #1 AWG | #1/0 AWG |

| 150-200 feet | #1 AWG | #1/0 AWG | #2/0 AWG |

Nota: Values assume 600V DC system with <2% voltage drop. Increase one wire size for 1000V systems or >2% drop acceptance.

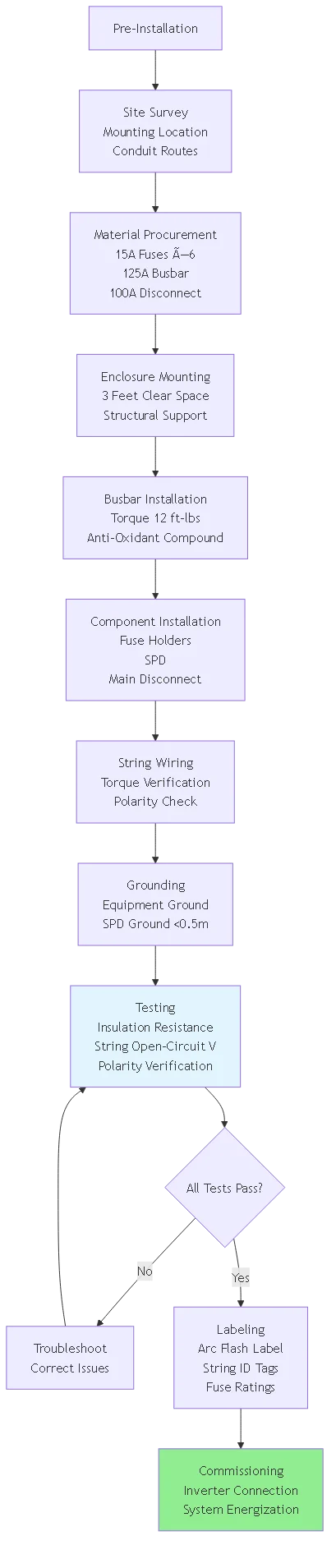

Optimal Combiner Box Placement:

1. Electrical center of string array

– Minimizes total string cable length

– Reduces voltage drop and copper cost

– Typical location: center of 6-string subarray

2. Accessibility requirements

– Minimum 3 feet clear working space (NEC 110.26)

– 6.5 feet minimum headroom

– Locked enclosure if publicly accessible

3. Environmental considerations

– Avoid direct southern exposure (reduces internal temps 10-15°C)

– Mount on north-facing walls or under eaves when possible

– Sunshield highly recommended for black/dark enclosures

4. Structural support

– Combiner boxes weigh 40-80 lbs when fully populated

– Requires 3/8″ stainless steel mounting bolts minimum

– Back-plate mounting preferred over direct wall attachment

6 String Combiner Standard Entry Pattern:

– String inputs: 6× ¾” conduits (top entry preferred)

– Main output: 1× 1¼”-2″ conduit (bottom exit)

– Grounding: 1× ¾” conduit for equipment ground conductor

– Comunicazione (if monitored): 1× ½” conduit for data cables

Weatherproofing Requirements:

– All conduit entries require watertight hubs

– Silicone seal around hub-to-enclosure interface

– Drip loops on all cables before entry

– Bottom entries preferred for drain holes

🎯 Suggerimento professionale: Install conduit entries with slight downward angle (5-10°) to prevent water pooling inside hubs. Even “watertight” fittings can accumulate condensation over time.

Commercial 6 string systems often include per-string monitoring to identify underperforming strings before annual energy loss becomes significant.

Monitoring Level 1: Voltage-Only

– Monitors combined string voltage at busbar

– Detects complete string failure only

– Lowest cost (~$50 per combiner box)

– Inadequate for proactive maintenance

Monitoring Level 2: Individual String Current (Recommended)

– Hall-effect current sensors on each string input

– Identifies underperforming strings in real-time

– Mid-range cost (~$200-400 per combiner box)

– ROI: Detects 5-10% string degradation within days

Monitoring Level 3: Full I-V Curve Tracing

– Automated I-V curve measurement per string

– Diagnostic-level troubleshooting capability

– Premium cost (~$800-1500 per combiner box)

– Best for utility-scale or critical applications

Commercial Recommendation: Level 2 monitoring provides optimal cost-performance for 50-200kW commercial systems. Payback period typically <2 years through improved o&m efficiency.

Problema: Specifying 100A busbar for 86A system leaves no margin for adding strings later.

Scenari comuni:

– Client requests 7th or 8th string addition within 2 years

– Busbar replacement requires complete combiner rebuild

– Lost opportunity cost >$2000 in labor and downtime

Correzione: Always specify busbar rated for +2 strings beyond initial design. For 6 string systems, use 150A busbar to accommodate future 8-string expansion with zero rework.

⚠️ Avvertenze: Busbar upgrade post-installation costs 5-8× more than initial oversizing. The $50 incremental cost of 150A vs 125A busbar provides enormous future flexibility.

Problema: Using different manufacturers’ fuses within the same combiner box creates unequal fault response and coordiation problems.

Scenari comuni:

– Mixing Bussmann and Littelfuse gPV fuses

– Using 15A and 20A fuses interchangeably

– Replacing blown fuses with incorrect ratings

Correzione: Specify single manufacturer and rating for all string fuses. Document in combiner box door label. Stock spare fuses of identical specification on-site.

Problema: Running SPD connections across the enclosure creates inductive loops that reduce protection effectiveness.

Typical bad practice:

– SPD mounted on door, busbar on back panel (lead length >1m)

– Coiled excess wire inside enclosure

– Sharp 90° bends in SPD conductors

Correzione: Mount SPD within 6 inches of busbar junction. Use shortest practical leads with gentle bends. Measure total lead length (positive + negative + ground) to verify <500mm.

Problema: Selecting components based on 30°C ratings when enclosure operates at 50-60°C.

Impact:

– Busbar operates above rated temperature

– Accelerated insulation degradation

– Nuisance breaker trips on hot days

Correzione: Apply NEC 310.15(B)(2) derating factors based on actual measured enclosure temperatures. For black enclosures in direct sun, assume 60°C ambient and derate all current ratings by 0.71×.

Commercial 6 string combiner boxes require annual inspection to ensure continued reliable operation:

Ispezione visiva:

– [ ] Enclosure door gasket intact and sealing properly

– [ ] No signs of water intrusion or corrosion

– [ ] All labels legible (replace if faded)

– [ ] No damaged conduit or loose fittings

– [ ] Busbar connections tight (no discoloration from overheating)

Electrical Testing:

– [ ] Measure string open-circuit voltages (all within 2% of expected)

– [ ] Insulation resistance test: >1MΩ to ground

– [ ] Verify SPD status indicator (green = functional)

– [ ] Torque check all busbar connections (12 ft-lbs)

– [ ] Thermographic scan under load (no hot spots >10°C above ambient)

Performance Verification:

– [ ] Compare string currents (all within 5% of average)

– [ ] Check for signs of fuse degradation or darkening

– [ ] Verify main disconnect operates smoothly

– [ ] Test monitoring system communication (if equipped)

Frequency: Annual inspection minimum, semi-annual for coastal or industrial environments.

Problem: One String Not Producing

Diagnostic steps:

1. Measure string open-circuit voltage → If 0V, check string fuse

2. If fuse blown, investigate cause before replacement:

– Ground fault on string?

– Module defect creating short circuit?

– Lightning strike damage?

3. Replace with identical fuse rating only

4. Monitor for 48 hours to ensure stable operation

Problem: All Strings Low Output

Possible causes:

– Busbar overheating due to loose connections

– SPD failed short, creating ground fault path

– Inverter DC input problem (not combiner box)

– Soiling or shading affecting all modules

Diagnostic:

– Thermographic scan of busbar system

– SPD status indicator check

– Individual string I-V curves to isolate issue

Problem: Nuisance Breaker Tripping

Root causes:

– Undersized breaker for actual current

– High ambient temperature reducing breaker rating

– Breaker defect or wrong trip curve

– Transient overcurrent from cloud-edge effects

Solution: Verify breaker rating vs actual maximum current with 1.25× safety factor. Consider upgrading to next standard size if marginal.

6 String Combiner Box Material Costs (Typical):

| Component | Standard Option | Premium Option |

|---|---|---|

| Enclosure (NEMA 3R/4X) | $250-400 | $600-1200 |

| 125A Copper Busbar | $80-120 | $150-200 (tin-plated) |

| 6× 15A gPV Fuses | $90-150 | $180-240 (premium brand) |

| 100A Load-Break Disconnect | $200-350 | $500-800 (UL 98B rated) |

| Type 2 DC SPD (40kA) | $120-200 | $300-500 (60kA rating) |

| String Monitoring (optional) | - | $200-400 |

| Hardware & Accessories | $50-100 | $100-150 |

| Total Material Cost | $790-1320 | $1830-3290 |

Labor Costs:

– Installation (4-6 hours): $400-900 depending on site complexity

– Testing and commissioning: $150-300

– Total installed cost: $1350-2500 (standard) or $2400-4500 (premium)

Choose Standard Components When:

– Inland locations with mild climate

– Easy rooftop access for maintenance

– Budget-conscious projects

– Residential-grade warranty acceptable (10 years)

Choose Premium Components When:

– Coastal environments (within 5 miles of ocean)

– Industrial facilities with corrosive atmospheres

– Difficult access sites (requires extended service life)

– Client requires 25+ year system warranty

ROI Calculation Example:

Standard 6-string combiner: $1,350 installed

– Fuse replacement every 5 years: $150 + $200 labor = $350

– Enclosure corrosion repair year 12: $800

– Total 25-year cost: $1,350 + $1,400 = $2,750

Premium 6-string combiner: $2,400 installed

– No fuse replacement (breaker inputs)

– No corrosion issues (NEMA 4X stainless)

– Total 25-year cost: $2,400

Savings: $350 over 25 years + reduced downtime risk

💡 Approfondimento chiave: Premium combiner boxes often provide lower lifecycle cost despite higher upfront investment. Payback period typically 10-15 years through reduced maintenance.

NEC 690.8 – Circuit Current Calculations:

– Maximum current = 1.25 × (number of parallel strings × I_sc)

– All overcurrent devices must be rated ≥125% of maximum current

– Conductor ampacity must account for temperature correction factors

NEC 690.13 – Disconnect Requirement:

– Combiner box output must have disconnect means

– Load-break rated if accessible by unqualified persons

– Maximum 6 operations for disconnect accessibility

– Must be lockable in open position

NEC 690.16 – Fuse/OCPD Requirements:

– String fuses required when ≥3 parallel strings

– Fuse rating ≤1.56 × module I_sc

– Fuses must be accessible for inspection without energized part exposure

NEC 690.35 – Surge Protection:

– Type 1 or Type 2 SPD required on DC side

– Grounded conductor SPD optional but recommended

– Follow manufacturer installation instructions for lead length

NEC 690.47 – Grounding:

– Equipment grounding conductor to all metallic enclosures

– Bonding bushing on metallic conduits

– Grounding electrode conductor to building ground system

NEC 110.26 – Working Space:

– Minimum 3 feet clear space in front of combiner box

– 30 inches wide working space

– 6.5 feet minimum headroom

– Illumination required for indoor locations

Required Labels on Combiner Box:

1. Arc Flash Warning (NFPA 70E)

– “DANGER – Arc Flash Hazard”

– Available incident energy (cal/cm²)

– Required PPE category

– Working distance

2. PV System Warning (NEC 690.12)

– “WARNING – Electric Shock Hazard”

– “Contact with energized parts may result in death”

– Voltage and current ratings

3. Component Identification

– String numbers (1-6) at fuse positions

– “Main Disconnect” label

– SPD replacement indicator

4. Manufacturer Information

– Company name and contact

– Installation date

– Fuse ratings and replacement parts

Standard combiner boxes accommodate 2-12 strings depending on configuration and busbar capacity. A 6 string combiner box is sized for 50-150kW commercial systems. Larger systems requiring more than 12 strings typically use multiple combiner boxes with parallel DC feeds to the inverter, allowing better distribution across large roof areas and easier future expansion.

Output wire sizing depends on combined string current and distance to inverter. For typical 6-string systems producing 60-80A, use #4 AWG copper for runs under 50 feet, #2 AWG for 50-100 feet, and #1 AWG for 100-150 feet. These sizes maintain voltage drop below 2% at maximum power point. Always verify with NEC 310.15(B) ampacity tables and apply temperature correction factors for your specific installation environment.

No, mixing fuse ratings creates coordination problems and unequal fault protection. All string fuses in a combiner box must have identical voltage and current ratings from the same manufacturer. Per NEC 690.16, fuse rating must not exceed 1.56 times the module short-circuit current. If your modules have 11.5A I_sc, all string fuses should be rated 15A (1.56 × 11.5A = 17.9A max).

Mount the combiner box at the electrical center of the string array to minimize total wire length and voltage drop. Choose a location with 3 feet clear working space (NEC 110.26), away from direct southern sun exposure to reduce internal temperatures. Avoid low points where water might pool and verify structural support for the 40-80 lb fully-loaded weight. If possible, mount on north-facing walls or add sunshields for black/dark enclosures.

Perform annual inspections minimum, including visual checks for corrosion, water intrusion, and loose connections, plus electrical testing of insulation resistance and string voltages. Coastal or industrial environments require semi-annual inspection due to increased corrosion risk. Monthly monitoring system checks identify performance issues between formal inspections. Thermal imaging scans every 2-3 years detect developing hot spots before failure occurs.

String monitoring is highly recommended for commercial systems but not required by code. Individual string current monitoring costs $200-400 per combiner box and typically pays back within 2 years through early detection of underperforming strings. Without monitoring, a single failed string can go undetected for months, losing 15-20% of system output. For 100kW commercial systems, this represents $1,500-3,000 in annual lost revenue.

NEMA 3R enclosures provide rain/sleet/snow protection but are not dust-tight or corrosion-resistant, adequate for most temperate climates at $250-400 for 6-string size. NEMA 4X enclosures offer full weatherproofing and corrosion resistance through stainless steel or fiberglass construction, required for coastal or industrial environments at $600-1200 but with 25+ year lifespan. Choose NEMA 4X for sites within 5 miles of ocean or with corrosive atmospheres.

Engineering a 6 string PV combiner box requires careful attention to busbar sizing, component selection, and NEC compliance to ensure 25+ years of reliable operation in commercial solar installations.

Punti di forza:

1. Busbar capacity must account for 125% of maximum string current with temperature derating applied for 50-60°C enclosure environments

2. Fuse coordination requires identical ratings across all strings (typically 15A gPV for 11-12A modules)

3. Enclosure selection impacts long-term maintenance costs – NEMA 4X premium upfront often provides lower lifecycle cost

4. SPD integration requires lead lengths <0.5m for effective lightning protection in commercial applications

5. String monitoring typically achieves 2-year payback through early detection of underperforming strings

Proper engineering of 6 string combiner boxes balances initial cost with long-term reliability, providing the foundation for profitable commercial solar operations.

Risorse correlate:

– DC Circuit Breaker Selection Guide for Commercial PV Systems

– Solar Fuse Sizing and Coordination for String Protection

– DC SPD Installation Standards for Lightning Protection

Ready to specify commercial-grade combiner boxes for your project? Contact SYNODE’s technical team for project-specific engineering support including busbar calculations, component selection, and NEC compliance verification for 50-200kW commercial solar installations. Our team provides detailed schematics and bill of materials optimized for your site conditions.

Ultimo aggiornamento: February 2026

Autore: Team tecnico SYNODE

Recensito da: Commercial Solar Engineering Department

Parola chiave di riferimento: Scatola combinatore pv a 6 stringhe

URL Slug: 6-string-pv-combiner-box-commercial-design

Meta Titolo: 6 String PV Combiner Box Design: Commercial System Engineering Guide

Meta descrizione: Complete 6 string PV combiner box engineering guide: busbar sizing, enclosure selection, string current calculations, and commercial installation standards for 50-200kW systems.

Livello di contenuto: Tier 3 (Supporting Content)

Funnel di conversione: Top of Funnel (consapevolezza)

Conteggio parole obiettivo: 2800-4000 parole

Diagrammi della sirena target: 3

Configurarli nelle impostazioni di Rank Math, quindi eliminare questa casella prima della pubblicazione.

Standard combiner boxes accommodate 2-12 strings depending on configuration and busbar capacity. A 6 string combiner box is sized for 50-150kW commercial systems. Larger systems requiring more than 12 strings typically use multiple combiner boxes with parallel DC feeds to the inverter, allowing better distribution across large roof areas and easier future expansion.

Output wire sizing depends on combined string current and distance to inverter. For typical 6-string systems producing 60-80A, use #4 AWG copper for runs under 50 feet, #2 AWG for 50-100 feet, and #1 AWG for 100-150 feet. These sizes maintain voltage drop below 2% at maximum power point. Always verify with NEC 310.15(B) ampacity tables and apply temperature correction factors for your specific installation environment.

No, mixing fuse ratings creates coordination problems and unequal fault protection. All string fuses in a combiner box must have identical voltage and current ratings from the same manufacturer. Per NEC 690.16, fuse rating must not exceed 1.56 times the module short-circuit current. If your modules have 11.5A I_sc, all string fuses should be rated 15A (1.56 × 11.5A = 17.9A max).

Mount the combiner box at the electrical center of the string array to minimize total wire length and voltage drop. Choose a location with 3 feet clear working space (NEC 110.26), away from direct southern sun exposure to reduce internal temperatures. Avoid low points where water might pool and verify structural support for the 40-80 lb fully-loaded weight. If possible, mount on north-facing walls or add sunshields for black/dark enclosures.

Perform annual inspections minimum, including visual checks for corrosion, water intrusion, and loose connections, plus electrical testing of insulation resistance and string voltages. Coastal or industrial environments require semi-annual inspection due to increased corrosion risk. Monthly monitoring system checks identify performance issues between formal inspections. Thermal imaging scans every 2-3 years detect developing hot spots before failure occurs.

String monitoring is highly recommended for commercial systems but not required by code. Individual string current monitoring costs $200-400 per combiner box and typically pays back within 2 years through early detection of underperforming strings. Without monitoring, a single failed string can go undetected for months, losing 15-20% of system output. For 100kW commercial systems, this represents $1,500-3,000 in annual lost revenue.

NEMA 3R enclosures provide rain/sleet/snow protection but are not dust-tight or corrosion-resistant, adequate for most temperate climates at $250-400 for 6-string size. NEMA 4X enclosures offer full weatherproofing and corrosion resistance through stainless steel or fiberglass construction, required for coastal or industrial environments at $600-1200 but with 25+ year lifespan. Choose NEMA 4X for sites within 5 miles of ocean or with corrosive atmospheres.