Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

A fusibile del pannello solare is a specialized overcurrent protection device designed to interrupt excessive current in photovoltaic systems before wiring overheats or equipment fails. Unlike general-purpose fuses, solar panel fuses must handle unique DC characteristics: no natural current zero-crossings, high inrush during cloud-edge effects, and continuous high-temperature operation in outdoor combiner boxes.

This comprehensive product guide explains solar panel fuse fundamentals from the ground up. We cover what makes DC-rated fuses different from AC fuses, how to read fuse specifications, the critical distinction between gPV and aM rated fuses, and the international standards (IEC 60269-6, UL 2579) that ensure fuse safety and reliability.

For solar installers, system designers, homeowners, and maintenance professionals, understanding solar panel fuse technology prevents the two most common specification errors: using AC-rated fuses in DC applications (catastrophic failure risk) and selecting incorrect current ratings (nuisance blowing or inadequate protection).

💡 Concetto di fondazione: A solar panel fuse is a sacrificial device containing a metal element that melts when current exceeds rating. The key difference for solar applications: DC arcs don’t self-extinguish at zero-crossings like AC, requiring special arc-quenching fillers and DC voltage ratings.

A complete solar panel fuse protection system consists of two components:

Fuse Link (Fuse Element):

– Metal element: Thin conductor (copper, silver, or zinc alloy) with calibrated cross-section

– Arc quenching filler: Silica sand (SiO₂) surrounding the element

– Body: Ceramic tube (porcelain or steatite) rated for high temperatures

– End caps: Copper or brass contacts with indicator (some models)

– Ratings marked: Voltage (e.g., 1500V DC), current (e.g., 15A), standard (gPV, IEC 60269-6)

Fuse Holder (Fuse Base):

– Contact clips: Spring-loaded copper alloy gripping fuse end caps

– Montaggio: DIN rail, panel mount, or PCB mount

– Wire terminals: Screw terminals or compression lugs

– Enclosure rating: IP20 (indoor) to IP67 (outdoor weatherproof)

– Indicator window: Visual blown fuse detection (optional)

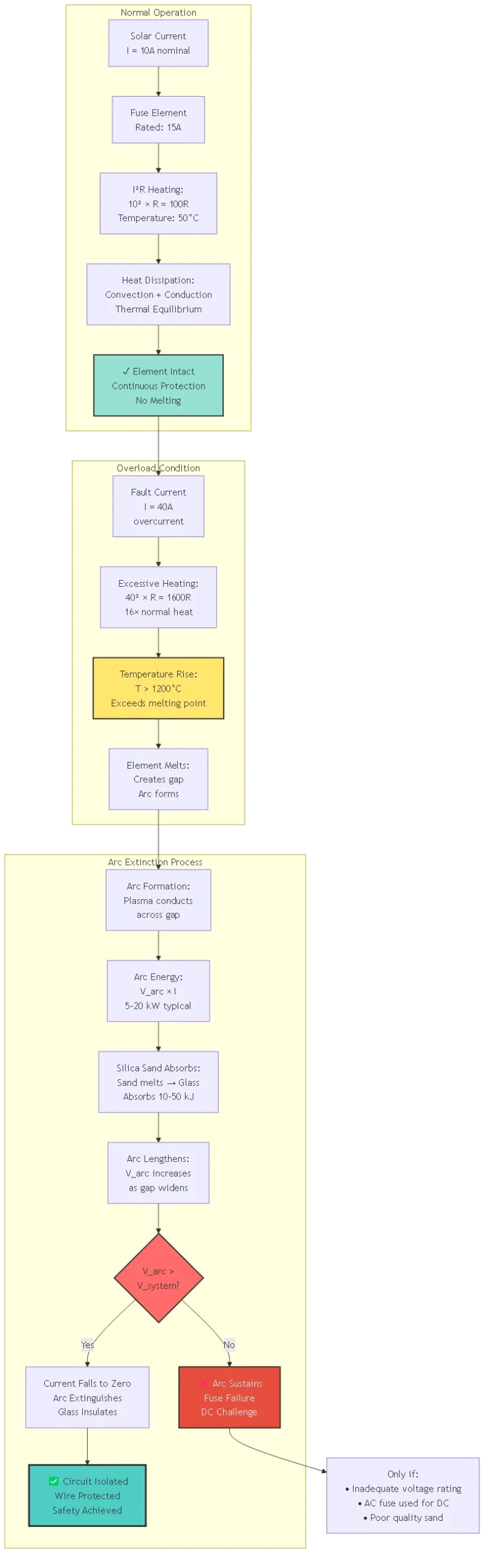

Stage 1 – Normal Operation:

– Current flows through metal element

– Element heats due to I²R losses

– Steady-state temperature: 40-70°C (design-dependent)

– Element cross-section sized for continuous current without melting

– Thermal balance: heat generation = heat dissipation

Stage 2 – Overload Condition:

– Current exceeds rated value

– I²R heating increases as square of current

– Element temperature rises above melting point (1000-1400°C depending on alloy)

– Time to melt depends on overcurrent magnitude (inverse time-current characteristic)

– Example: 150% overload may take 30-60 minutes, 300% overload takes 2-5 seconds

Stage 3 – Arc Interruption:

– Metal element melts, creating gap

– Arc forms across gap (conducting plasma)

– Silica sand absorbs arc energy

– Arc heats sand, creating glass (fulgurite)

– Glass is non-conductive, extinguishes arc

– Final state: permanent open circuit

Critical DC Challenge: DC arcs have continuous voltage trying to maintain plasma. High-quality silica sand and adequate fuse length (38mm, 58mm, or longer for high voltage) essential for reliable DC arc extinction.

AC vs DC Voltage Ratings:

| Tipo di fusibile | AC Voltage Rating | DC Voltage Rating | Reason for Difference |

|---|---|---|---|

| General Purpose Fuse | 250V AC | 60V DC (if rated) | AC zero-crossing aids extinction |

| Photovoltaic Fuse (gPV) | Not rated for AC | 1000V or 1500V DC | Enhanced arc quenching for DC |

| Fuse Length Impact | 10mm × 38mm (10A) | 14mm × 51mm (longer body) | Longer arc path for DC interruption |

Why You Cannot Use AC Fuses for DC:

AC fuses rely on current naturally crossing zero 100-120 times per second. At zero-crossing, arc extinguishes easily. DC has no zero-crossing—the arc sustains continuously. An AC-rated fuse in a DC circuit may:

– Fail to interrupt current (arc continues indefinitely)

– Overheat and explode

– Cause fire in combiner box

⚠️ Safety Critical: Always verify fuse is marked with DC voltage rating equal to or exceeding system voltage. A 250V AC fuse is NOT safe for 250V DC (it may only handle 60-125V DC).

Standard IEC Fuse Sizes:

| Size Code | Diameter × Length | Typical Current Range | Tensione nominale | Applicazione |

|---|---|---|---|---|

| 10×38 | 10mm × 38mm | 1-32A | Up to 1000V DC | Protezione delle stringhe residenziali |

| 14×51 | 14mm × 51mm | 2-63A | Up to 1500V DC | Commercial string protection |

| 22×58 | 22mm × 58mm | 10-125A | Up to 1500V DC | Array mains, combiner outputs |

UL Class Sizes (North America):

| Classe | Dimensioni | Current Range | Tensione | Applicazione |

|---|---|---|---|---|

| CC | 13/32″ × 1-1/2″ | 1-30A | 600 V CC | Solare residenziale |

| T | 13/32″ × 1-1/4″ | 1-15A | 300V DC | Low voltage systems |

| Midget | 13/32″ × 1-1/2″ | 1-30A | 600-1000V DC | String protection |

Physical Compatibility: Fuse holders are size-specific. A 10×38 fuse will not fit in a 14×51 holder. When replacing fuses, match both physical size AND electrical ratings.

gPV Rating Classification:

The “gPV” designation means “general purpose Photovoltaic fuse” per IEC 60269-6:

– g = general purpose (full-range breaking from small overloads to maximum short circuit)

– PV = photovoltaic application specific

– Replaces older “gR” (general purpose fast-acting) designation for PV

Requisiti chiave:

1. DC Voltage Rating:

– Must be marked with DC voltage (e.g., 1000V DC, 1500V DC)

– Cannot exceed system open-circuit voltage (V_oc) at coldest temperature

– Altitude derating: -10% per 1000m above 2000m elevation

2. Current Rating (I_n):

– Nominal current: fuse carries indefinitely without blowing

– Rated at 25°C ambient

– Must derate for higher temperatures inside combiner boxes (often 50-70°C)

3. Breaking Capacity (I_max):

– Minimum 50 kA for gPV fuses (sufficient for solar applications)

– Some industrial fuses rated 120 kA

– Solar fault currents rarely exceed 5-10 kA (limited by module I_sc)

4. Time-Current Characteristic:

– Conventional fusing current (I_f): Current that causes fusing in 2 hours

– Typically I_f = 1.45 × I_n (fuse rated 15A fuses at 21.75A in 2 hours)

– Conventional non-fusing current (I_nf): Current carried for 2 hours without fusing

– Typically I_nf = 1.25 × I_n (fuse rated 15A carries 18.75A for 2 hours)

5. I²t Rating (Let-Through Energy):

– Energy allowed through fuse before clearing: ∫ I²(t) dt

– Critical for protecting semiconductors (inverter inputs)

– Lower I²t = faster fuse, better protection for sensitive equipment

Scope and Application:

UL 2579 covers fuses specifically designed for photovoltaic systems, including:

– String fuses (series-connected modules)

– Combiner fuses (parallel strings)

– Array fuses (main protection)

Key Differences from IEC:

| Aspetto | IEC 60269-6 | UL 2579 |

|---|---|---|

| Voltage Classes | 1000V DC, 1500V DC standard | 600V DC common, 1000V DC, 1500V DC |

| Size Designation | 10×38, 14×51, 22×58 (mm) | Class CC, T, Midget (inches) |

| Marking Requirements | gPV marking mandatory | PV marking, DC voltage, current |

| Temperature Testing | 25°C, 40°C, 70°C ambient | 40°C, 60°C ambient (higher) |

| Arc Interruption Test | L/R = 15ms time constant | X/R ratio varies by rating |

NEC Requirements:

National Electrical Code Article 690.9 mandates:

– Overcurrent device rated for DC voltage

– Located on both positive and negative conductors (ungrounded systems)

- Accessibile per la manutenzione

– Interrupting rating ≥ available fault current

aM Rating (Motor Protection):

– a = partial range breaking (only interrupts short circuits, not small overloads)

– M = motor circuit protection

– Fast-acting for short circuits (I > 10× I_n)

– Does NOT protect against small overloads (1.5-3× I_n)

When aM Used in Solar:

– Older designs before gPV standard

– Should not be used in new installations

– Risk: Won’t clear moderate overcurrent conditions

gPV Rating (General Purpose PV):

– g = full-range breaking (protects against all overcurrents)

– Clears overloads AND short circuits

– Required for complete wire protection per NEC 690.9

🎯 Specification Rule: Always specify gPV-rated fuses for solar panel protection. Never use aM-rated fuses for string or combiner protection—they provide incomplete protection.

Formula for Solar String Fuse:

I_fuse ≥ I_sc × 1.56

Dove:

– I_sc = module short-circuit current (from datasheet)

– 1.56 = combined factor (1.25 for high irradiance × 1.25 for continuous operation)

Step-by-Step Example:

Sistema: Residential rooftop, 400W modules, I_sc = 11.24A

Step 1 – Identify I_sc:

– Module datasheet: I_sc = 11.24A at STC (1000 W/m², 25°C)

Step 2 – Apply NEC multiplier:

– I_fuse_min = 11.24A × 1.56 = 17.53A

Step 3 – Select standard rating:

– Standard fuse ratings: 10A, 12A, 15A, 16A, 20A, 25A…

– Selected: Fusibile da 20A (next size above 17.53A)

Step 4 – Verify non-nuisance operation:

– Fuse conventional non-fusing current: I_nf = 20A × 1.25 = 25A

– Maximum string current: 11.24A × 1.25 (high irradiance) = 14.05A

– 14.05A < 25A ✓ (fuse won’t nuisance blow during normal operation)

Fuses are rated at 25°C ambient. Inside a combiner box on a rooftop, ambient can reach 50-70°C.

Derating Formula:

I_actual = I_rated × k_temp

Where k_temp is temperature correction factor:

| Temperatura ambiente | k_temp | Effective Current Rating (15A fuse example) |

|---|---|---|

| 25°C | 1.00 | 15.0A |

| 40°C | 0.95 | 14.25A |

| 50°C | 0.90 | 13.5A |

| 60°C | 0.85 | 12.75A |

| 70°C | 0.80 | 12.0A |

Example with Temperature Correction:

– Calculated minimum: 17.53A

– Standard fuse: 20A

– Combiner box temperature: 60°C (typical rooftop in summer)

– Derated capacity: 20A × 0.85 = 17.0A

– Problema: 17.0A < 17.53A required

Soluzione: Select next size up:

– 25A fuse nominal

– At 60°C: 25A × 0.85 = 21.25A ✓

– Adequate margin for hot operation

⚠️ Design Practice: For rooftop combiner boxes, assume 60°C ambient minimum. For desert installations, use 70°C. Select fuse rating with temperature derating applied.

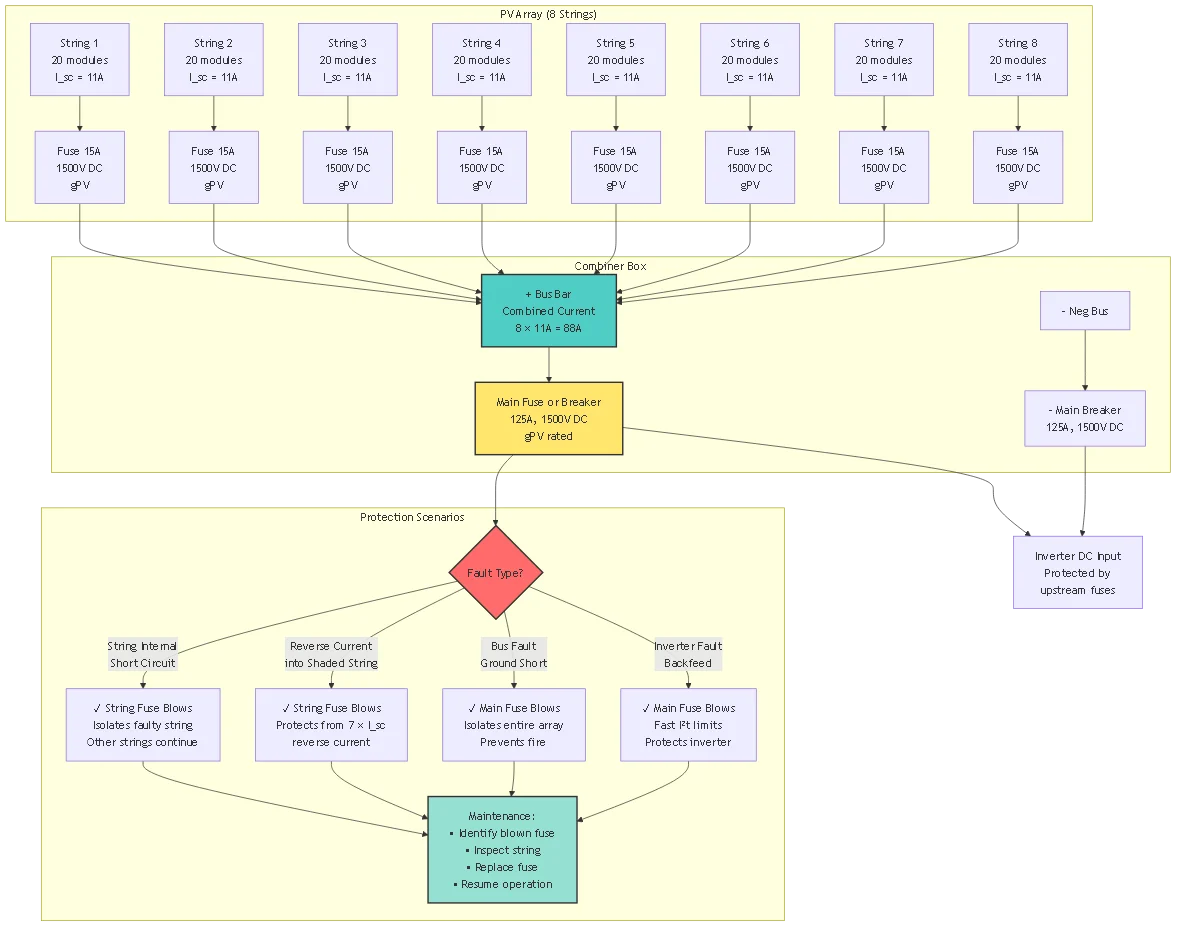

Reverse Current Scenario:

In arrays with multiple parallel strings, if one string is shaded or fails short-circuit, other strings can discharge into it:

– Array: 8 parallel strings, I_sc = 10A each

– String #3 shorts to ground

– Reverse current into String #3: 7 strings × 10A = 70A

NEC 690.9(A) Requirement:

Strings must be protected from reverse current if:

Calculated reverse current > fuse rating × 1.35

Calcolo:

I_reverse = (N – 1) × I_sc

Dove:

– N = number of parallel strings

– I_sc = short-circuit current per string

Esempio:

– 8 parallel strings, I_sc = 10A

– I_reverse = (8 – 1) × 10A = 70A

– Module datasheet max series fuse rating: 20A (typical specification)

– 70A > 20A × 1.35 → Fuses required ✓

When Fuses NOT Required:

For small arrays:

– 2 parallel strings: I_reverse = 1 × I_sc = I_sc → Often no fuse needed

– Check module datasheet “Maximum Series Fuse Rating”

– If I_reverse < specified fuse rating, fuses may be omitted

Modern Practice: Most installers fuse all strings for serviceability and troubleshooting ease, even if NEC doesn’t require it.

Indoor Combiner Boxes (Controlled Environment):

– IP20 minimum: Protected against >12mm objects, no water protection

– Typical application: Equipment room, basement, utility closet

– Cost: $5-15 per fuse holder

Outdoor Combiner Boxes (Rooftop, Ground Mount):

– IP65 minimum: Dust-tight, protected against water jets

– IP67 recommended: Dust-tight, protected against temporary immersion

– Required features: Gaskets, sealed terminals, weatherproof cover

– Cost: $15-35 per fuse holder

Coastal/Marine Environments:

– IP67 minimum with corrosion-resistant materials

– Stainless steel or nickel-plated brass terminals

– UV-resistant polymer housing

– Cost: $25-50 per fuse holder

DIN Rail Mount Fuse Holders:

Vantaggi:

✅ Tool-free installation (snap onto 35mm rail)

✅ High density (narrow width: 6-12mm per fuse)

✅ Easy rearrangement and addition

✅ Modular design for system expansion

Svantaggi:

❌ Requires DIN rail infrastructure in combiner box

❌ Limited wire size accommodation (6-10 AWG typically)

❌ More expensive per position ($12-25)

Panel Mount Fuse Holders:

Vantaggi:

✅ Lower cost ($5-15 per holder)

✅ Larger wire terminals (4-1/0 AWG capacity)

✅ Can be positioned anywhere on panel

✅ Simple mounting (2-4 screws)

Svantaggi:

❌ Requires drilling mounting holes

❌ Fixed position (harder to reconfigure)

❌ Lower density (3-4″ spacing typical)

Guida alla selezione:

– Residential systems (<20kW): DIN rail for clean, professional installation

– Commercial systems (20-500kW): Panel mount for heavy wire capacity

– Utility-scale (>500kW): Custom bus bar systems with bolt-in fuses

Visual Indicators:

Striker Pin Indicator:

– Small pin protrudes from fuse end cap when element melts

– Visible through fuse holder window

– Mechanical operation (no electronics)

– Cost: +$2-5 per fuse vs non-indicating

LED Indicator Modules:

– Separate LED module detects voltage drop across fuse

– Lights when fuse is blown

– Requires small auxiliary power (2-5W)

– Cost: $20-40 per indicator module

Remote Monitoring:

– Fuse status transmitted to monitoring system

– Integration with SCADA or inverter monitoring

– Dry contact or Modbus output

– Cost: $50-150 per monitored position

Value Analysis:

– Small systems (1-4 strings): Visual indicators adequate

– Medium systems (5-20 strings): LED indicators improve troubleshooting speed

– Large systems (>20 strings): Remote monitoring justified by reduced truck rolls

| Aspetto | Solar Panel Fuse | Interruttore CC |

|---|---|---|

| Tempo di risposta | Very fast (1-5 cycles) I²t limited | Fast (3-10 cycles) Higher let-through |

| Resettability | ❌ Single-use Must replace | ✅ Resettable Unlimited trips |

| Costo | Low initial: $3-15 Replacement cost each trip | High initial: $30-120 No replacement cost |

| Precision | ✅ Tight tolerance ±10% current rating | ⚠️ Wider tolerance ±20% current rating |

| Size | Compact: 10-22mm diameter High density | Larger: 18-72mm width Lower density |

| Manutenzione | Replace after trip Stock spares required | Reset switch No parts stocking |

| Failure Mode | Open circuit (safe) | Can weld closed (hazard) |

Use Fuses For:

✅ String-level protection: Individual PV strings in combiner boxes

– Reason: Low cost per string (8 strings × $10 = $80 vs 8 breakers × $40 = $320)

– Infrequent faults (strings rarely fail)

– High protection precision

✅ Inverter input protection: DC input to inverter

– Reason: Ultra-fast I²t limits protect sensitive semiconductor

– Fuse I²t (10-50 A²s) << breaker let-through (200-1000 A²s)

✅ Battery bank cell-level protection: Individual cell strings

– Reason: Fast response to internal cell short circuit

– Compact size for dense battery packs

Use Circuit Breakers For:

✅ Combiner output (array main): Main disconnect after all strings combine

– Reason: Resettable for troubleshooting and maintenance

– Lower long-term cost (multiple nuisance trips during commissioning)

✅ Accessible locations: Equipment accessible to operators

– Reason: Reset without technician dispatch

– Visible trip indication

✅ Frequent switching: Applications requiring regular isolation

– Reason: Unlimited mechanical operations

– Fuses not designed for make/break duty

Hybrid Approach (Common in Commercial Systems):

– String level: Fuses (15A gPV, 1500V DC)

– Combiner output: Circuit breaker (160A, 1500V DC)

Total cost for 10-string system:

– Fuses: 10 × $12 + 10 × $8 holders = $200

– Main breaker: $250

– Totale: $450

Compare to all-breaker approach:

– 10 string breakers: 10 × $40 = $400

– Main breaker: $250

– Totale: $650

Hybrid saves $200 (31%) while maintaining high performance.

No—absolutely not. AC fuses rely on current naturally crossing zero 100-120 times per second where the arc self-extinguishes. DC has no zero-crossings; the arc sustains continuously. A 250V AC fuse may only safely handle 60-125V DC due to arc extinction challenges. Using AC fuses in DC solar applications creates catastrophic failure risk: the arc may not extinguish, causing fuse explosion, combiner box fire, or sustained fault current that damages wiring and modules. Always verify fuses are marked with DC voltage rating (e.g., “1500V DC”) and gPV designation per IEC 60269-6 or UL 2579 certification for photovoltaic applications.

Use NEC 690.9 formula: I_fuse ≥ I_sc × 1.56, where I_sc is module short-circuit current from datasheet. The 1.56 factor accounts for high irradiance conditions (1.25× normal) and continuous operation derating (1.25× thermal). Select the next standard fuse rating above calculated value. Example: module I_sc = 11A gives 11 × 1.56 = 17.16A minimum, so select 20A fuse. Then verify temperature derating for combiner box environment—rooftop boxes can reach 60-70°C, requiring 15-20% capacity margin. If combiner at 60°C, 20A fuse effectively becomes 20 × 0.85 = 17A, which is marginal; select 25A instead.

“gPV” stands for “general purpose Photovoltaic fuse” per IEC 60269-6 standard. The “g” means full-range breaking capability: the fuse protects against both small overloads (1.5-3× rated current) and high short circuits (up to 50kA+). The “PV” designation means the fuse passed specialized tests for photovoltaic applications: DC arc interruption at 1000-1500V DC, high ambient temperature performance (70°C), and reverse current protection. This distinguishes from “aM” (motor) fuses which only interrupt short circuits, not overloads, providing incomplete protection. NEC 690.9 requires full overcurrent protection, making gPV-rated fuses mandatory for proper PV string and combiner protection.

Fuses are “replace-on-failure” devices with no scheduled replacement interval if they haven’t blown. A properly sized, unblown fuse can remain in service for 20-30 years (the system lifetime). However, visual inspection during annual maintenance is recommended: check for discoloration (overheating), corrosion on end caps, or cracks in ceramic body. Replace if any degradation visible. In harsh environments (coastal salt spray, desert dust, extreme temperature cycling), consider 10-year replacement as preventive measure. After a fuse blows, never just replace it without investigating root cause—repeated fuse failures indicate system fault (shading, module failure, ground fault, or undersized fuse rating).

Physical size determines voltage rating and breaking capacity, not current rating. A 15A / 1000V DC fuse comes in both 10×38mm and 14×51mm sizes. The larger 14×51mm provides: (1) Higher breaking capacity—longer body allows more silica sand for arc energy absorption, enabling interruption of higher fault currents; (2) Better heat dissipation—larger surface area keeps element cooler in high ambient temperatures; (3) Higher voltage capability—some 14×51mm fuses rated 1500V DC while 10×38mm typically maxes at 1000V DC. Choose 10×38mm for residential systems (space-constrained) with moderate fault levels; use 14×51mm for commercial/utility systems with higher available fault currents and 1500V DC systems. Ensure fuse holder matches physical size.

NEC 690.9(A) requires overcurrent protection on both ungrounded conductors in most PV systems. For typical ungrounded (floating) systems without direct ground reference, this means fuses on BOTH positive and negative strings. If system is grounded (negative conductor bonded to earth), only the positive conductor requires fusing per NEC 690.9(B). Reason: fault from positive to ground creates return path through grounded negative, requiring positive fuse to clear. Modern practice: even in grounded systems, many installers fuse both polarities for symmetry and troubleshooting simplicity. Cost difference minimal (2× fuses instead of 1×) but simplifies maintenance and ensures protection regardless of ground fault location.

Visual inspection methods: (1) Indicator pin—many gPV fuses have small striker pin that protrudes from end cap when element melts; visible through fuse holder window; (2) Window inspection—some ceramic fuse bodies have transparent section showing element; if element appears severed or blackened, fuse is blown; (3) System behavior—if one string’s voltage reads 0V while others read normally, that string’s fuse likely blown. For definitive verification without removing fuse: use voltage measurement across fuse terminals; >0.5V drop indicates open (blown) fuse. Do NOT rely on fuse appearance alone—element can melt internally without visible external signs. For quick field check, keep sacrificial “known-good” fuse to swap-test suspected position.

Solar panel fuses represent critical overcurrent protection technology specifically engineered for photovoltaic applications. Unlike general-purpose AC fuses, solar fuses must interrupt sustained DC arcs at voltages up to 1500V DC, withstand continuous high-temperature operation in outdoor combiner boxes, and provide precise current ratings matching solar module specifications.

Key Technology Fundamentals:

DC-Specific Design: Solar panel fuses employ enhanced silica sand arc-quenching fillers and longer body lengths (14×51mm, 22×58mm) to reliably extinguish DC arcs that lack natural zero-crossings. The gPV rating per IEC 60269-6 certifies full-range overcurrent protection from 1.25× rated current overloads through 50kA+ short circuits.

Proper Sizing Methodology: NEC 690.9 mandates fuse current rating ≥ I_sc × 1.56 (1.25 for high irradiance × 1.25 for continuous operation). Temperature derating essential for rooftop installations—60°C combiner boxes reduce fuse capacity 15%, requiring next size up from calculation.

Standards Compliance: IEC 60269-6 (international gPV standard) and UL 2579 (North American PV fuse standard) ensure proper DC arc interruption, voltage withstand, and time-current characteristics. Never substitute AC-rated fuses or aM (motor) rated fuses—incomplete protection and catastrophic failure risk.

Strategic Application: Fuses excel at string-level protection where compact size, low cost ($8-15), and ultra-fast I²t limiting protect modules and wiring. Circuit breakers better suited for array mains and frequently-switched positions. Hybrid approach (fused strings + breaker main) optimizes cost and performance.

For solar installers, system designers, and maintenance professionals, proper solar panel fuse selection and application ensures safe, reliable PV systems that protect personnel, equipment, and property throughout 25-30 year system lifetimes.

Related Solar Protection Resources:

– Solar Fuses System Design – Multi-level protection strategies

– Design della scatola combinatore FV – Complete combiner specifications

– DC SPD Coordination – Surge protection integration

Product Support: SYNODE offers application engineering support for solar fuse selection, temperature derating calculations, and NEC compliance verification. Contact our technical team for system-specific recommendations and combiner box design review services.

Ultimo aggiornamento: Ottobre 2025

Autore: SYNODE Product Engineering Team

Revisione tecnica: Solar Design Engineers, NABCEP Certified Specialists

Standards Referenced: IEC 60269-6:2016, UL 2579:2021, NEC Article 690:2023