Endereço

304 North Cardinal

St. Dorchester Center, MA 02124

Horas de trabalho

De segunda a sexta-feira: das 7h às 19h

Fim de semana: 10:00 - 17:00

Endereço

304 North Cardinal

St. Dorchester Center, MA 02124

Horas de trabalho

De segunda a sexta-feira: das 7h às 19h

Fim de semana: 10:00 - 17:00

Selecting the right waterproof outdoor electrical box is critical for protecting solar PV electrical connections from moisture, dust, and environmental damage. Unlike standard indoor enclosures, outdoor electrical boxes must withstand rain, humidity, temperature extremes, and UV exposure while maintaining reliable electrical protection. This comprehensive guide explains everything professional installers and engineers need to know about specifying, installing, and maintaining waterproof outdoor electrical boxes for solar installations.

A waterproof outdoor electrical box achieves moisture protection through multiple integrated design features. The enclosure material itself resists water penetration, while gasket seals prevent moisture ingress at doors and cable entry points. Proper waterproofing also requires correct IP (Ingress Protection) rating selection based on the installation environment.

True waterproofing goes beyond splash resistance. A properly specified waterproof box protects internal components during heavy rain, prevents condensation buildup, and maintains sealing integrity through thousands of thermal expansion cycles. For solar PV applications, this protection is essential because electrical connections carry high DC voltages that become dangerous when exposed to moisture.

Principais percepções: The difference between “water-resistant” and “waterproof” is legally significant. Water-resistant boxes offer splash protection but aren’t suitable for direct rain exposure. Always specify boxes with minimum IP65 rating for outdoor solar installations.

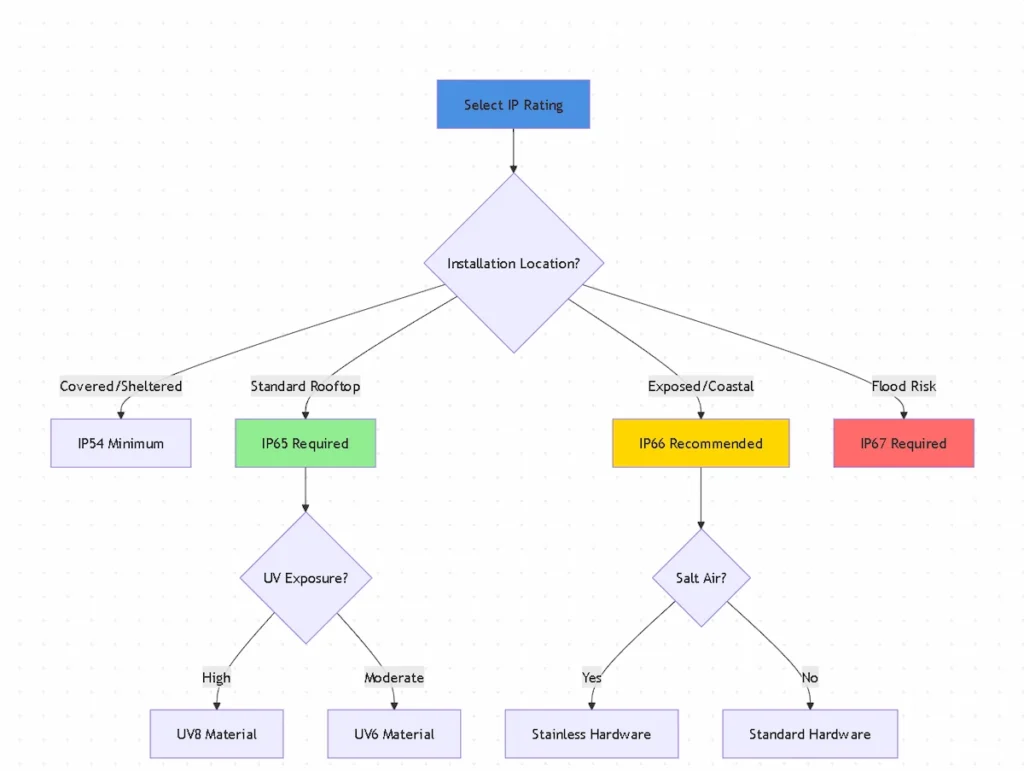

The IP rating system provides standardized waterproofing classification. The second digit indicates liquid ingress protection: IP64 offers splash protection, IP65 protects against water jets, IP66 withstands powerful water jets, and IP67 survives temporary immersion. Most solar installations require IP65 or IP66 rated caixas de distribuição à prova d'água for adequate weather protection.

IP ratings consist of two digits that define protection levels against solid objects and liquids. The first digit (0-6) indicates dust protection, while the second digit (0-9) specifies moisture protection. For outdoor electrical enclosures, both digits matter because dust and moisture often occur together in harsh environments.

Common IP ratings for solar PV installations include IP65, IP66, and IP67. IP65 boxes protect against dust ingress and low-pressure water jets from any direction. IP66 provides dust-tight sealing and withstands powerful water jets, making it suitable for exposed installations. IP67 offers the same dust protection but can survive temporary water immersion up to 1 meter depth.

Selection depends on specific installation conditions. Rooftop installations with good drainage typically require IP65 minimum. Ground-mounted systems in flood-prone areas need IP67 protection. Coastal installations exposed to driving rain and salt spray perform best with IP66 rating combined with corrosion-resistant materials.

⚠️ Importante: An IP rating only guarantees protection when all cable entries use proper glands and the door gasket remains intact. A single loose cable gland compromises the entire enclosure’s waterproof rating.

| Installation Environment | Minimum IP Rating | Second Digit Meaning | Aplicação típica |

|---|---|---|---|

| Covered/Sheltered | IP54 | Splash resistant | Under eaves, carports |

| General Outdoor | IP65 | Water jet resistant | Standard rooftop solar |

| Exposed/Coastal | IP66 | Powerful jet resistant | Ground-mount, coastal areas |

| Flood Risk Areas | IP67 | Temporary immersion | Low-lying installations |

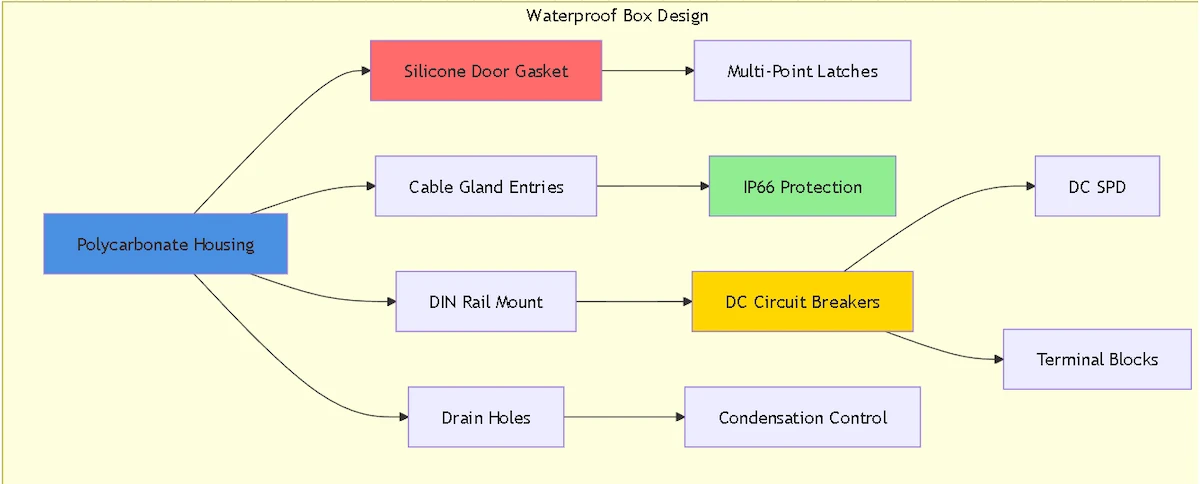

Waterproof outdoor electrical boxes are manufactured from three primary materials: polycarbonate plastic, ABS plastic, and metal (steel or aluminum). Each material offers distinct advantages for different solar PV applications and environmental conditions.

Polycarbonate boxes provide excellent UV resistance, impact strength, and temperature stability. High-quality polycarbonate maintains structural integrity from -40°C to +120°C, making it ideal for extreme climates. The material naturally resists yellowing and brittleness from sun exposure. Polycarbonate boxes are lightweight, simplifying rooftop installation while maintaining durability.

ABS plastic boxes offer good chemical resistance and cost-effectiveness for less demanding applications. While ABS provides adequate strength for many installations, it degrades faster under prolonged UV exposure than polycarbonate. ABS works well for covered installations or locations with minimal direct sunlight. However, for exposed rooftop solar arrays, UV-stabilized polycarbonate delivers superior long-term performance.

Metal enclosures (stainless steel or powder-coated aluminum) provide maximum physical security and electromagnetic shielding. Metal boxes excel in high-temperature environments and where vandalism concerns exist. However, metal requires careful grounding and conducts heat, potentially creating thermal management challenges. Metal boxes also cost more than plastic alternatives and require proper gasket maintenance to prevent galvanic corrosion at sealing surfaces.

Dica profissional: For solar PV installations, UV-stabilized polycarbonate offers the best balance of durability, weight, and cost. Specify material with minimum UV8 rating (8000+ hours UV exposure resistance) for installations with direct sun exposure.

Effective waterproof outdoor electrical boxes incorporate specific design features that ensure reliable long-term protection. Understanding these features helps specify boxes that maintain sealing integrity throughout their service life.

Gasketed doors create the primary moisture barrier at the box opening. Quality gaskets use closed-cell foam or silicone rubber that maintains compression over years of thermal cycling. The door should incorporate multiple stainless steel latches with adequate closing force to maintain consistent gasket compression. Single-latch designs often develop gaps as gaskets age and compress.

Cable gland entries provide sealed penetrations for incoming and outgoing cables. Pre-molded knockout holes with metric or PG threads accept standard cable glands. The box should offer multiple entry locations (top, bottom, sides) for flexible cable routing. Unused entries require blind plugs with O-ring seals to maintain IP rating.

Internal mounting rails allow secure component installation using DIN rail mounting. Quality boxes include Disjuntores de corrente contínua, Fusíveis CCe DC SPDs on easily removable rails. Rail mounting simplifies field modifications and component replacement compared to fixed mounting points.

Drain holes prevent water accumulation inside the enclosure. Despite waterproof design, condensation can form during temperature fluctuations. Small drain holes at the bottom allow condensation to escape while maintaining IP rating through labyrinth-style hole design that prevents direct water entry.

✅ Continuous silicone or foam rubber gasket

✅ Multiple corrosion-resistant latches

✅ Pre-threaded cable gland entries

✅ Removable DIN rail mounting

✅ Condensation drain holes

✅ Grounding terminal provision

✅ Transparent or translucent cover option

✅ UV-stabilized material (UV8 minimum)

❌ Single latch closure systems

❌ Compression gaskets without door stops

❌ Unthreaded knockout holes

❌ Fixed mounting without rail system

❌ No drain hole provision

❌ Materials without UV stabilization

Proper box sizing ensures adequate space for components while allowing safe working clearances and future expansion. Undersized boxes create installation difficulties, while oversized boxes waste money and mounting space.

Calculate required internal volume by listing all components with dimensions. Include Disjuntores de corrente contínua, Chaves seccionadoras CC, dispositivos de proteção contra surtos, terminal blocks, and any monitoring equipment. Add 30% additional space for cable bending radius and future component additions.

Consider NEC (National Electrical Code) clearance requirements for DC circuits. Article 110.26 specifies minimum working space around electrical equipment. While these requirements primarily address accessibility during maintenance, they also ensure adequate wire bending space that prevents insulation damage and maintains proper conductor separation.

Standard waterproof box dimensions follow metric sizing: 200x200x100mm for small residential systems, 300x400x150mm for typical residential arrays, and 400x600x200mm for commercial installations. Depth particularly matters because DIN rail components typically require 90-120mm depth plus cable bending space.

Principais percepções: Calculate cable entry requirements before finalizing box size. Each cable requires proper strain relief and bending radius. A box with adequate volume but insufficient cable entries forces improvised solutions that compromise IP rating.

Residential 10kW Solar Array:

Proper installation determines whether a waterproof outdoor electrical box maintains its IP rating throughout its service life. Even boxes with excellent design fail when incorrectly mounted or with improperly installed cable glands.

Orientação de montagem significantly affects water drainage and internal condensation. Always mount boxes with cable entries pointing downward or sideways, never upward. Top cable entry allows rain to pool around glands and eventually penetrate through capillary action. Orient the box to minimize direct sun exposure on the door gasket when possible, as gaskets degrade faster under UV exposure.

Cable gland installation requires careful attention to detail. Strip cable jacket to expose individual conductors, but maintain enough jacket inside the gland to grip properly. Tighten the compression nut until firm resistance indicates proper seal, but avoid overtightening that deforms the gland body. Install blind plugs with O-rings in all unused entries.

Gasket maintenance during installation preserves sealing performance. Inspect the door gasket for damage before closing. Clean mating surfaces to remove dust or debris that prevents complete gasket compression. Apply silicone grease to gaskets before first closure to prevent initial sticking and establish proper seal. Verify all latches engage fully and maintain even door pressure.

Grounding connections ensure safety and protect against lightning-induced surges. Connect the box’s internal ground bar to the system’s equipment grounding conductor. For metal enclosures, also bond the box exterior to the grounding system. Use corrosion-resistant grounding hardware suitable for outdoor exposure.

⚠️ Importante: Never drill additional holes in waterproof boxes without proper sealing provisions. Each penetration compromises IP rating. If modifications are necessary, use only cable glands rated for the box’s IP class, install with sealant, and verify integrity.

Waterproof outdoor electrical boxes serve multiple critical functions in solar PV installations. Understanding typical applications helps specify appropriate box configurations for different system locations.

String combiner applications house components that combine multiple solar panel strings before connecting to inverters. A typical Caixa combinadora fotovoltaica includes DC string fuses or circuit breakers, surge protection devices, and monitoring connections. These boxes mount near solar arrays and experience full weather exposure, requiring robust waterproofing.

DC disconnect applications provide manual isolation for safety during maintenance. Boxes housing Chaves seccionadoras CC must be accessible to service personnel but protected from unauthorized operation. Transparent covers allow switch position verification without opening the enclosure and compromising weather protection.

Inverter isolation applications protect inverter DC inputs with appropriately rated overcurrent protection. These boxes typically mount within 3 meters of inverters and contain DC circuit breakers rated for the system voltage. Compact waterproof boxes work well here because short cable runs minimize voltage drop.

Surge protection applications house DC SPDs that protect against lightning-induced transients. SPD boxes require grounding connections with minimal impedance, making their mounting location critical. The waterproof enclosure must accommodate SPD thermal disconnectors and status indicators while maintaining all-weather protection.

| Aplicativo | Key Components | Tamanho típico | Special Requirements |

|---|---|---|---|

| Combinador de cordas | Fuses, SPDs, terminals | 400x600x200mm | Multiple string entries |

| Desconexão CC | Isolator switch | 300x400x150mm | Visible switch position |

| Entrada do inversor | DC breaker, monitoring | 300x400x150mm | Close proximity mounting |

| Surge Protection | DC SPD, ground bar | 200x300x120mm | Low-impedance ground path |

Despite proper specification and installation, moisture problems occasionally develop in outdoor electrical boxes. Systematic troubleshooting identifies root causes and guides effective repairs.

Condensation vs. leakage requires different solutions. Condensation forms when warm, humid air enters the box and contacts cooler internal surfaces. This indicates inadequate sealing but not direct water entry. Actual leakage shows water accumulation after rain events, indicating compromised waterproofing at specific entry points.

Inspect gaskets first when moisture appears. Age-hardened gaskets lose compression and develop gaps. Replace gaskets showing cracks, permanent deformation, or lost elasticity. Clean gasket seating surfaces thoroughly before installing new gaskets. Apply thin silicone grease to new gaskets to improve sealing and prevent premature aging.

Check cable glands methodically. Loosen each gland and verify proper cable grip. The compression ring should bite into the cable jacket, creating a visible indentation. Glands that spin freely on cables have lost sealing capability. Replace damaged glands and ensure proper cable diameter for the gland size. Oversized glands cannot seal effectively regardless of tightening force.

Verify door latch operation ensures consistent gasket compression. Latches wear over time, reducing closing force. Multi-latch doors should engage all latches simultaneously with equal tension. Replace bent or corroded latches that prevent uniform door pressure.

Dica profissional: Install moisture-absorbing desiccant packs inside boxes with persistent condensation issues. This addresses symptoms while you resolve the root cause. Replace desiccant every 6 months in humid climates.

Regular maintenance extends waterproof box service life and prevents moisture-related failures. Establishing an inspection schedule appropriate to local climate conditions ensures reliable long-term performance.

Inspeções anuais should occur before and after severe weather seasons. Examine door gaskets for cracking, compression set, or hardening. Test door latches for proper engagement and closing force. Inspect cable glands for loosening or visible gaps. Check internal components for corrosion or moisture staining indicating past water entry.

Bi-annual cleaning prevents dirt buildup that degrades gasket sealing. Wipe gasket seating surfaces with clean, lint-free cloths. Remove dust and debris from door surfaces. Clean transparent covers to maintain visibility of internal components. Avoid abrasive cleaners that scratch polycarbonate surfaces and reduce UV resistance.

Substituição da junta typically occurs every 3-5 years depending on climate and UV exposure. Harsh environments with extreme temperature cycling require more frequent replacement. Replace gaskets showing any cracking, permanent deformation, or lost elasticity. Keep spare gaskets on site to minimize downtime during maintenance.

Cable gland inspection should accompany any internal component work. Verify tightness and proper sealing. Replace any glands showing cracks in the housing or damaged compression rings. Update blind plugs if cable configurations change during system modifications.

Annual Inspection:

Cleaning Tasks:

3-5 Year Replacement:

Waterproof outdoor electrical boxes for solar PV applications must comply with relevant electrical and environmental standards. Understanding these requirements ensures proper specification and regulatory compliance.

IEC 60529 defines the IP rating system used worldwide. This standard establishes test methods for verifying dust and water ingress protection. Boxes claiming specific IP ratings must pass standardized testing protocols. Third-party certification provides verification that boxes meet claimed ratings.

IEC 60670 specifies requirements for boxes and enclosures for electrical accessories. Part 24 specifically addresses enclosures for installation equipment (distribution boards). This standard defines mechanical strength, electrical properties, and environmental resistance requirements.

UL 50 (US standard) addresses enclosures for electrical equipment. UL Type ratings (Type 4, 4X, 6, 6P) define weather resistance levels similar to IP ratings. Type 4 provides weather protection equivalent to approximately IP66. Type 6P offers temporary submersion resistance similar to IP67.

Artigo 314 do NEC (US) governs outlet, device, pull, and junction boxes. Requirements include proper sizing calculations, support methods, and conductor fill limitations. While focused on wiring methods, these rules affect waterproof box selection and installation.

Principais percepções: When exporting solar equipment internationally, verify both IP ratings (international) and UL Type ratings (US market) for complete market coverage. Many manufacturers provide dual certification for global market access.

Quality variations among waterproof outdoor electrical boxes significantly affect long-term reliability. Knowing what distinguishes premium boxes from basic enclosures guides purchasing decisions that reduce lifetime costs.

Material quality indicators include UV stabilization ratings, impact resistance specifications, and temperature range certifications. Request UV8 minimum rating for exposed installations. Verify IK (impact) ratings if vandalism concerns exist. Check temperature specifications match your climate extremes.

Gasket quality separates excellent boxes from adequate ones. Premium boxes use medical-grade silicone or EPDM rubber gaskets that maintain elasticity for years. Budget boxes often use cheaper foam that compresses permanently within months. Examine gasket cross-section—better gaskets are thicker (3-5mm) with multiple sealing ribs.

Qualidade do hardware affects long-term functionality. Stainless steel latches and hinges resist corrosion far better than zinc-plated steel. Look for continuous piano hinges rather than individual hinge points that create stress concentrations. Verify latches are replaceable without removing the entire door.

Documentação de certificação from third-party testing labs validates manufacturer claims. Request IP rating test reports, not just datasheets claiming ratings. UL, TÜV, or equivalent marks indicate independent verification. Beware of self-certified claims without testing lab documentation.

Solução SYNODE: SINODO caixas de distribuição à prova d'água feature UV8-stabilized polycarbonate construction, continuous silicone gaskets, and stainless steel hardware. Third-party IP66 certification ensures reliable weather protection for demanding solar PV applications.

Waterproof outdoor electrical box costs vary significantly based on size, features, and quality. Understanding total cost of ownership rather than just purchase price guides economically sound decisions.

Initial purchase costs range from $30 for basic small boxes to $500+ for large commercial enclosures. Premium materials, higher IP ratings, and additional features increase costs. However, this represents a small fraction of total solar installation cost—typically 1-2% for residential systems.

Mão de obra de instalação often exceeds box costs. Properly installing cable glands, mounting securely, and verifying sealing takes skilled labor time. Quality boxes with well-designed features reduce installation time through easier cable routing and component mounting. Time saved during installation often justifies higher box costs.

Custos de manutenção differ dramatically between quality tiers. Premium boxes with quality gaskets and hardware may require minimal maintenance for 10+ years. Budget boxes often need gasket replacement within 2-3 years plus more frequent inspections. Service call costs quickly exceed initial savings from cheaper boxes.

Custos de falhas make quality critical. A moisture-compromised box can damage expensive protection components like Disjuntores de corrente contínua ou DC SPDs. Worse, moisture-caused failures may create safety hazards or system downtime. Lost production during repairs on commercial systems makes reliability essential.

| Box Quality | Custo inicial | Maintenance | Risco de falha | Custo total |

|---|---|---|---|---|

| Budget | $50 | $200 | $500 | $750 |

| Mid-Range | $100 | $100 | $150 | $350 |

| Premium | $180 | $50 | $20 | $250 |

What IP rating do I need for a rooftop solar installation?

Rooftop solar installations typically require IP65 minimum rating for adequate weather protection. This rating protects against dust ingress and water jets from any direction, suitable for rain exposure. Installations in areas with driving rain, coastal environments, or extreme weather should specify IP66 for enhanced protection. IP67 becomes necessary only for ground-mounted systems in flood-prone locations where temporary submersion might occur.

Can I use an indoor electrical box outdoors if I shelter it?

No, never use indoor boxes for outdoor solar installations even under shelter. Indoor boxes lack proper gasket sealing, UV-resistant materials, and moisture barriers. Temperature cycling creates condensation inside sheltered areas, damaging components. Weather exposure degrades non-UV-stabilized materials regardless of rain protection. Always specify properly rated caixas de distribuição à prova d'água with appropriate IP ratings for any outdoor electrical connection.

How do I know when to replace the door gasket?

Replace gaskets showing visible cracking, permanent compression set (doesn’t spring back when pressed), or hardening that prevents flexibility. Annual inspection should check gasket condition. Most gaskets require replacement every 3-5 years depending on UV exposure and temperature extremes. If moisture appears inside the box after rain, inspect and likely replace the gasket regardless of age. Preventive replacement costs far less than component damage from moisture ingress.

What’s the difference between water-resistant and waterproof?

Water-resistant boxes offer splash protection but aren’t designed for continuous or direct water exposure. Waterproof boxes meet specific IP ratings (typically IP65+) with verified testing against water jet exposure. Legally and technically, only boxes tested to IEC 60529 standards and marked with IP ratings should be called waterproof. Water-resistant is a marketing term without standardized testing requirements. For solar PV installations, always specify waterproof boxes with documented IP ratings.

Can I drill holes in a waterproof box for additional cables?

Drilling additional holes compromises the box’s IP rating and warranty. Each penetration must use a properly sized cable gland or blind plug to maintain waterproofing. If additional entries are necessary, use only cable glands rated for the box’s IP class, apply sealant, and install according to manufacturer specifications. Consider selecting a box with more pre-threaded entries than currently needed to accommodate future modifications without compromising protection.

Do metal boxes provide better protection than plastic?

Not necessarily—material choice depends on application requirements. Metal boxes offer superior impact resistance and heat dissipation but require careful grounding and cost more. UV-stabilized polycarbonate boxes provide excellent weather resistance, UV stability, and lighter weight at lower cost. For most solar PV applications, quality polycarbonate boxes deliver better overall value. Metal becomes advantageous for high-security locations or extreme temperature environments. Both materials can achieve equivalent IP ratings with proper design.

How close to the inverter should I mount the DC disconnect box?

NEC Article 690.13 requires readily accessible disconnecting means for photovoltaic system circuits. Mount DC disconnect boxes within sight and reach of the inverter, typically within 1-3 meters. This allows safe inverter servicing while minimizing DC cable runs that contribute to voltage drop. The box should be accessible without climbing or reaching overhead but positioned to prevent unauthorized operation. Consider local code requirements, which may specify maximum distances or mounting heights.

Selecting and installing waterproof outdoor electrical boxes correctly is fundamental to solar PV system reliability and longevity. The right enclosure protects critical electrical components from moisture, dust, and environmental degradation while ensuring decades of safe operation.

Key selection factors include appropriate IP rating for the installation environment, quality materials with UV stabilization, robust gasket sealing systems, and adequate sizing for components plus future expansion. Premium boxes with quality construction deliver superior total cost of ownership compared to budget alternatives that require frequent maintenance and risk costly failures.

Professional installation practices—proper mounting orientation, correct cable gland installation, gasket maintenance, and adequate grounding—determine whether a box maintains its IP rating throughout its service life. Regular inspection and preventive maintenance further ensure reliable weather protection.

Principais conclusões:

SYNODE manufactures professional-grade waterproof distribution boxes engineered specifically for solar PV applications. Our enclosures feature UV8-stabilized polycarbonate construction, continuous silicone gaskets, and third-party verified IP66 ratings for reliable all-weather protection.

SYNODE Waterproof Box Advantages:

Our distribution boxes integrate seamlessly with SYNODE Disjuntores de corrente contínua, Fusíveis CC, DC SPDse Chaves seccionadoras CC for complete solar protection solutions. CE, TÜV, and UL certifications ensure global compliance.

Ready to specify waterproof boxes for your next solar project? Contact SYNODE’s technical team for application-specific recommendations and competitive quotations. We support solar professionals in 50+ countries with reliable products and expert guidance.