Adresse

304 Nord Kardinal

St. Dorchester Center, MA 02124

Arbeitszeiten

Montag bis Freitag: 7AM - 7PM

Am Wochenende: 10AM - 5PM

Adresse

304 Nord Kardinal

St. Dorchester Center, MA 02124

Arbeitszeiten

Montag bis Freitag: 7AM - 7PM

Am Wochenende: 10AM - 5PM

Understanding the proper specification of a pv combiner box with circuit breaker is essential for compliant and reliable photovoltaic installations. These critical components combine multiple solar array strings while providing overcurrent protection, serving as the first line of defense in your solar power system architecture.

NEC Article 690.9 mandates overcurrent protection for PV source circuits when required by specific conditions. The selection between fuses and circuit breakers, proper sizing methodology, and environmental rating requirements directly impact system safety, maintenance costs, and code compliance.

This comprehensive guide provides detailed specification parameters, selection criteria, and decision matrices for pv combiner boxes with circuit breakers. We’ll examine voltage ratings, current calculations, breaker vs fuse selection, and environmental enclosure ratings for residential and commercial applications.

💡 Key Specification Insight: The choice between fused and circuit breaker-based combiner boxes involves trade-offs in first cost, maintenance accessibility, and long-term operational expenses—not just component price comparison.

A pv combiner box with circuit breaker is an electrical enclosure that consolidates multiple photovoltaic source circuits into a single output circuit while providing individual circuit protection through miniature circuit breakers (MCBs) or molded case circuit breakers (MCCBs). Unlike fuse-based combiners, circuit breaker configurations offer resettable overcurrent protection without component replacement after fault events.

PV Combiner Function: Combines parallel-connected solar array strings to reduce wire count and simplify connections to inverters or charge controllers. A typical 6-string combiner reduces six individual home runs to a single main output conductor.

Circuit Breaker Protection: Provides overcurrent interruption rated for DC current at specified voltage levels (600VDC, 1000VDC, or 1500VDC). DC-rated breakers use magnetic blowout or enhanced arc chutes to extinguish DC arcs that lack natural zero-crossing current points.

With vs Without: The “with circuit breaker” designation distinguishes active protection models from pass-through junction boxes. NEC 690.9 dictates when overcurrent protection is mandatory versus optional based on string conductor ampacity and available fault current.

When specifying a pv combiner box with circuit breaker, these parameters define system compatibility:

1. DC Voltage Rating: Maximum system voltage the breakers and box can safely interrupt (UL 1077 for supplementary protectors, UL 489 for branch circuit breakers)

2. Current Rating Per String: Breaker ampacity based on NEC 690.8(A)(1) calculation (Isc × 1.56 for crystalline modules)

3. Number of Inputs: String circuit quantity (typically 2-12 strings for residential, up to 24+ for commercial)

4. Environmental Rating: NEMA 3R/4/4X or IP rating determining outdoor/indoor placement and corrosion resistance

5. Main Output Rating: Combined current capacity at the output terminals connecting to inverter or next combiner stage

Real-World Example: A 600VDC residential combiner box with six 15A circuit breakers (for strings producing 13.2A Isc) consolidates six strings into a single 90A output circuit, reducing inverter DC disconnector requirements.

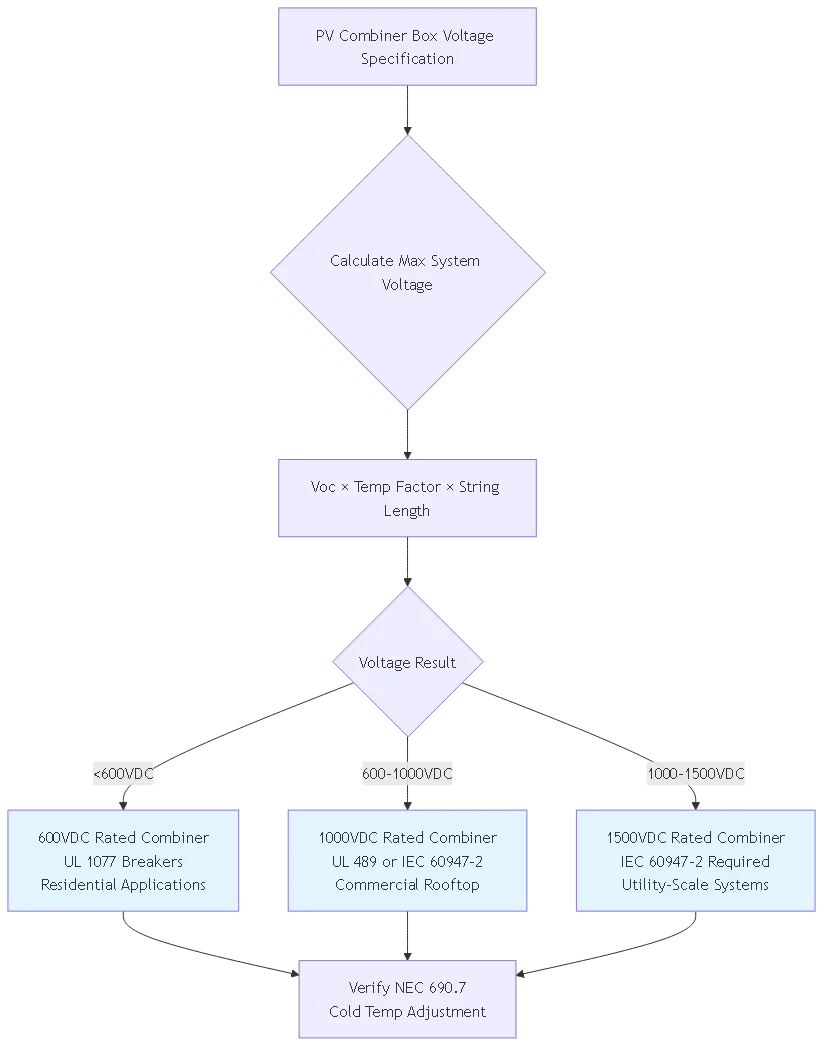

The DC voltage rating represents the maximum system voltage the combiner components can safely interrupt during fault conditions. Specification must account for cold temperature open-circuit voltage increases per NEC 690.7.

NEC 690.7 Calculation: Maximum system voltage = Voc × temperature coefficient × lowest expected temperature. For example, modules rated 45.6V Voc in a location with -20°C minimum: 45.6V × 1.14 = 51.98V per module. A 12-module string requires a 624VDC rating, necessitating a 1000VDC combiner box.

| Voltage Rating | Typische Anwendung | Max String Length | Normen |

|---|---|---|---|

| 600VDC | Residential systems | 8-10 modules | UL 1741, UL 1077 |

| 1000VDC | Commercial rooftop | 18-22 modules | UL 489, IEC 60947-2 |

| 1500VDC | Utility-scale systems | 28-35 modules | IEC 60947-2 |

⚠️ Critical Specification Warning: Never specify a 600VDC combiner box for a system that may experience >600V under cold conditions. Temperature deration of Voc is mandatory per NEC 110.3(B)—equipment must be used in accordance with listing requirements.

Individual string circuit breaker ratings must accommodate the calculated maximum circuit current per NEC 690.8(A)(1). The standard calculation multiplies module short-circuit current (Isc) by 1.56.

Calculation Method:

– Module Isc rating: 11.5A (from module datasheet)

– NEC 690.8(A)(1) calculation: 11.5A × 1.56 = 17.94A

– Breaker selection: Next standard size ≥17.94A = 20A circuit breaker

– Conductor sizing: 20A × 1.25 = 25A minimum ampacity (NEC 690.8(B)(1))

The main output breaker combines all parallel string currents. For a six-string combiner with 20A breakers per string: 6 × 17.94A = 107.64A calculated current, requiring a 125A main breaker.

NEMA and IP ratings define the mechanical and environmental protection level of the combiner enclosure.

| Bewertung | Protection Level | Typische Anwendung |

|---|---|---|

| NEMA 3R | Rain-resistant, outdoor | Rooftop installations |

| NEMA 4X | Watertight, corrosion-resistant | Coastal, washdown areas |

| IP65 | Dust-tight, water jet protected | European installations |

Coastal Environment Specification: Projects within 10 miles of saltwater require NEMA 4X stainless steel or fiberglass construction. Standard painted steel NEMA 3R boxes experience accelerated corrosion within 3-5 years.

🎯 Pro Specification Tip: Always specify gasket material for NEMA 3R+ enclosures. UV-resistant closed-cell foam gaskets maintain seal integrity for 15+ years, while standard rubber gaskets degrade in 5-7 years under direct sunlight exposure.

The fundamental decision between circuit breaker and fuse-based overcurrent protection impacts initial cost, maintenance requirements, and long-term operational characteristics.

Circuit Breaker Advantages:

– ✅ Resettable operation eliminates replacement cost after fault events

– ✅ Visual trip indication simplifies troubleshooting

– ✅ No inventory requirements for spare components

– ✅ Simultaneous disconnect function for maintenance isolation

Circuit Breaker Disadvantages:

– ❌ Higher initial component cost (2-4× fuse holder cost)

– ❌ Larger physical footprint per circuit

Fuse-Based System Advantages:

– ✅ Lower initial equipment cost

– ✅ Simpler construction with fewer mechanical components

– ✅ Compact design allows more circuits per enclosure

Fuse-Based System Disadvantages:

– ❌ Replacement cost and inventory management burden

– ❌ Requires de-energization and physical access for replacement

– ❌ No visual indication of operated fuse without testing

Initial Cost Comparison (6-string combiner, 1000VDC):

– Fuse-based combiner box: $450-650

– Breaker-based combiner box: $1,200-1,800

– Initial premium: $750-1,150 for breaker configuration

Operating Cost Projection (25-year system life):

– Expected fault events: 0-3 events

– Fuse replacement cost per event: $30-60 per string

– Service call cost: $150-350 per incident

– Breaker reset: $0 (homeowner-accessible)

Breakeven Analysis: Systems with >2-3 expected fault events over 25 years favor circuit breaker specification.

💡 Specification Consideration: Remote or difficult-access installations strongly favor circuit breaker specification due to service access challenges for fuse replacement.

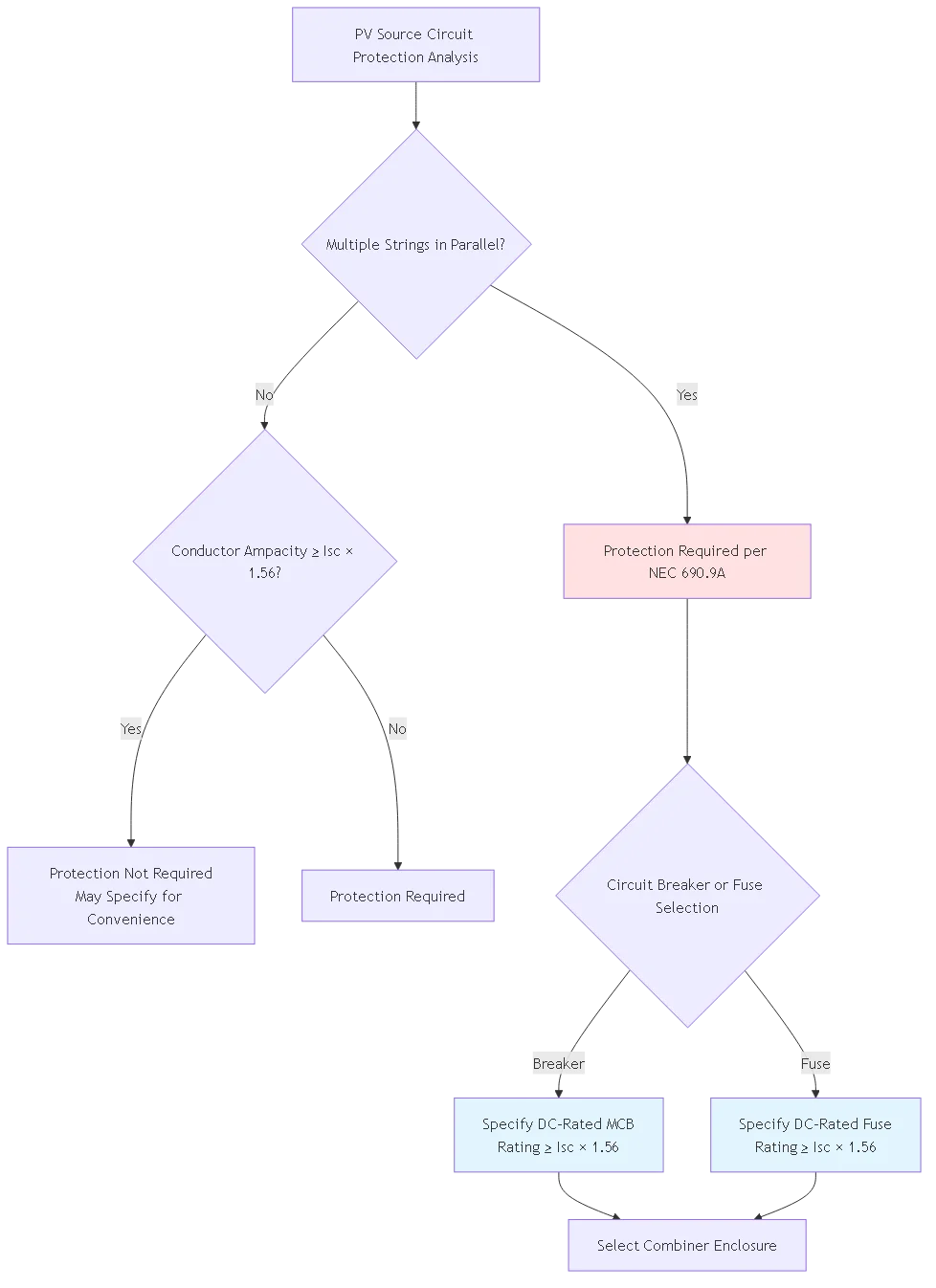

NEC 690.9(A) specifies conditions requiring overcurrent protection on PV source circuits.

Protection Required When:

1. Multiple Source Circuits in Parallel: Two or more PV source circuits connect in parallel

2. Conductor Ampacity Exceeded: Calculated PV source circuit current (Isc × 1.56) exceeds conductor ampacity

3. Equipment Input Rating Exceeded: Multiple parallel strings deliver combined current exceeding equipment rating

Protection Not Required When:

– Single source circuit connected directly to utilization equipment

– Conductor ampacity equals or exceeds sum of all parallel-connected source circuit currents

Critical Interpretation: A three-string system with conductors rated for 3 × Isc × 1.56 does NOT require individual string protection per NEC 690.9(A) exception. However, specifying protection provides troubleshooting benefits.

DC-rated circuit breakers carry both continuous current ratings and interrupt ratings. The interrupt rating must equal or exceed available fault current.

Fault Current Calculation:

– Maximum parallel string contribution: Number of strings × (Isc × 1.25)

– Total available fault current: Sum of parallel string contributions

A 10-string system with 12A Isc experiences maximum fault current of: 10 × 12A × 1.25 = 150A. Most DC MCBs rated for PV applications carry 3kA-10kA interrupt ratings.

⚠️ Code Compliance Warning: NEC 690.9(B) requires PV output circuit overcurrent protection. Ensure combiner main output breaker addresses both source circuit combination and output circuit protection.

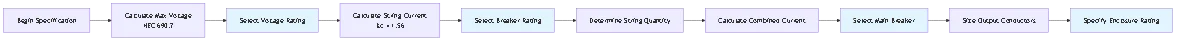

Combiner box input capacity specification depends on array architecture and future expansion considerations.

Step 1: Current Array Configuration

– Count total strings in array design

– Verify all strings carry equivalent current

Step 2: Future Expansion Planning

– Add 20-30% spare capacity for residential installations

– Commercial projects: specify exactly for phase 1

Example Specification:

– Current system: 6 strings @ 400W each

– String specification: 11.2A Isc, requiring 20A breakers

– Recommendation: Specify 8-position combiner box with 6 breakers installed

Sizing Calculation:

1. Calculate combined string current: Number of strings × (Isc × 1.56)

2. Select main breaker ≥ calculated current

3. Size output conductor for 125% of main breaker rating

6-String Example:

– String current: 11.5A Isc × 1.56 = 17.94A each

– Combined current: 6 × 17.94A = 107.64A

– Main breaker selection: 125A

– Output conductor: 1/0 AWG copper (170A @ 75°C)

🎯 Pro Sizing Tip: Specify main breaker ratings matching standard inverter DC input breaker sizes (63A, 80A, 100A, 125A, 150A) to simplify protection coordination.

| String Quantity | Combined Current | Main Breaker |

|---|---|---|

| 2 strings | 36A | 40A or 50A |

| 4 strings | 72A | 80A |

| 6 strings | 108A | 125A |

| 8 strings | 144A | 150A |

Problem: Specifying combiner boxes rated for nominal system voltage without accounting for cold-temperature Voc increases per NEC 690.7.

Häufige Szenarien:

– Using module nameplate Voc without temperature correction

– Specifying equipment based on inverter MPPT voltage range

Berichtigung: Always calculate maximum system voltage using NEC 690.7(A): Voc (STC) × temperature correction factor. For systems near 600V, specify 1000VDC-rated equipment.

Problem: Selecting breaker ratings based on module Isc without applying NEC 690.8(A)(1) multiplier of 1.56.

Häufige Szenarien:

– Using nominal operating current (Imp) instead of Isc

– Forgetting the 1.56 NEC multiplier

Berichtigung: Calculate string breaker rating as Isc × 1.56, then select next standard breaker size.

Problem: Specifying NEMA 3R enclosures for coastal or high-corrosion environments.

Häufige Szenarien:

– Using standard residential boxes within 10 miles of saltwater

– Failing to specify corrosion-resistant internal components

Berichtigung: Coastal installations require NEMA 4X stainless steel or fiberglass construction.

Problem: Specifying individual string breakers without main output overcurrent protection.

Häufige Szenarien:

– Assuming individual string protection satisfies all NEC requirements

– Omitting main breaker to reduce cost

Berichtigung: Every combiner box with multiple inputs requires a main output breaker sized per NEC 690.8 calculations.

A pv combiner box with circuit breaker uses resettable mechanical devices for overcurrent protection, while fuse-based combiners use one-time sacrificial elements requiring replacement after operation. Circuit breakers offer visual trip indication and reset capability without component replacement.

The fundamental trade-off involves higher initial equipment cost for breakers (typically 2-4× fuse holder cost) against lower operational expenses over system lifetime. Breakers provide simultaneous disconnect function for safe maintenance.

For installations with expected fault events >2-3 over 25 years, or remote locations where service access is challenging, circuit breaker specification demonstrates clear economic advantage.

Calculate individual string breaker size using NEC 690.8(A)(1) methodology: multiply the module short-circuit current (Isc from datasheet) by 1.56, then select the next standard breaker size equal to or greater than the calculated value.

For example, a module rated 13.2A Isc requires: 13.2A × 1.56 = 20.59A, necessitating a 25A breaker. This 1.56 multiplier accounts for module operation at irradiance levels exceeding Standard Test Conditions.

After calculating breaker size, verify conductor ampacity meets NEC 690.8(B)(1) requirements: the selected breaker rating × 1.25.

NEC 690.9(A) requires overcurrent protection when multiple PV source circuits connect in parallel, unless exception conditions are met. The requirement states protection is needed when “the sum of maximum currents from all parallel-connected source circuits exceeds conductor ampacity or equipment rating.”

The critical exception allows omitting individual string protection when conductors are sized for the sum of all parallel-connected source circuit currents. However, most designers specify individual string protection for fault localization and maintenance isolation.

Specify NEMA 3R minimum for outdoor installations in standard environments (residential rooftops, commercial buildings in non-coastal locations). NEMA 3R provides rain resistance adequate for typical outdoor electrical equipment.

Upgrade to NEMA 4X for coastal installations (within 10 miles of saltwater), industrial environments with chemical exposure, or locations subject to washdown requirements. NEMA 4X provides watertight construction and corrosion-resistant materials.

The equipment cost premium of 40-60% for NEMA 4X over 3R justifies itself through extended enclosure lifespan (20+ years vs 10-12 years).

Never use AC-only circuit breakers in DC applications, regardless of current rating. DC current lacks the zero-crossing points inherent in AC waveforms, requiring fundamentally different arc interruption mechanisms.

DC-rated breakers meeting UL 489 or UL 1077 incorporate magnetic blowout coils, enhanced arc chutes, or extended contact gaps specifically engineered for DC arc interruption. Using AC breakers in DC applications violates NEC 110.3(B) and creates liability exposure.

Specify integrated string-level monitoring for commercial systems exceeding 50kW, remote installations where on-site troubleshooting visits incur significant travel cost, or systems where performance optimization is prioritized. String monitoring enables early detection of underperformance due to shading, soiling, or module degradation.

Residential systems below 15kW rarely justify monitoring cost ($150-400 per combiner) unless site access is severely restricted. For commercial projects, calculate monitoring ROI based on O&M labor savings from rapid fault localization.

A “600V nominal solar system” requires voltage rating specification based on NEC 690.7 maximum system voltage calculations, not the nominal MPPT operating range. Calculate maximum system voltage as: module Voc × temperature correction factor × number of modules in series.

For example, modules rated 48V Voc at -20°C minimum: 48V × 1.14 = 54.7V per module. A 10-module string reaches 547V, safely accommodated by 600VDC equipment. An 11-module string reaches 602V, requiring 1000VDC-rated components.

Never specify equipment at its exact rating limit. Provide safety margin for unexpected conditions.

Proper specification of a pv combiner box with circuit breaker requires systematic analysis of voltage ratings, current calculations, environmental conditions, and long-term operational requirements.

Key Specification Takeaways:

1. Voltage ratings must accommodate NEC 690.7 cold-temperature calculations, not nominal system voltage

2. String breaker sizing follows NEC 690.8(A)(1) methodology using Isc × 1.56 multiplier

3. Circuit breaker vs fuse decision requires total cost analysis including fault frequency and service accessibility

4. Environmental enclosure ratings impact long-term reliability—NEMA 3R for standard, NEMA 4X for coastal

5. Integrated monitoring justification depends on system size—commercial >50kW demonstrate clear ROI

The specification phase establishes system safety, reliability, and operational characteristics for decades of service life.

Related Resources:

– PV Combiner Box Complete Guide: Types, Sizing & NEC Requirements

– DC Circuit Breaker Specifications and Selection for Solar Applications

– DC Fuse vs Circuit Breaker: PV System Protection Comparison

Ready to specify code-compliant pv combiner boxes with circuit breakers for your installation? Contact SYNODE’s technical team for project-specific recommendations based on your system voltage, string current requirements, and installation environment. We help ensure proper combiner box specification meeting all NEC 690.9 requirements.

Zuletzt aktualisiert: Oktober 2025

Autor: SYNODE Technisches Team

Rezensiert von: Fachbereich Elektrotechnik