Adresse

304 Nord Kardinal

St. Dorchester Center, MA 02124

Arbeitszeiten

Montag bis Freitag: 7AM - 7PM

Am Wochenende: 10AM - 5PM

Adresse

304 Nord Kardinal

St. Dorchester Center, MA 02124

Arbeitszeiten

Montag bis Freitag: 7AM - 7PM

Am Wochenende: 10AM - 5PM

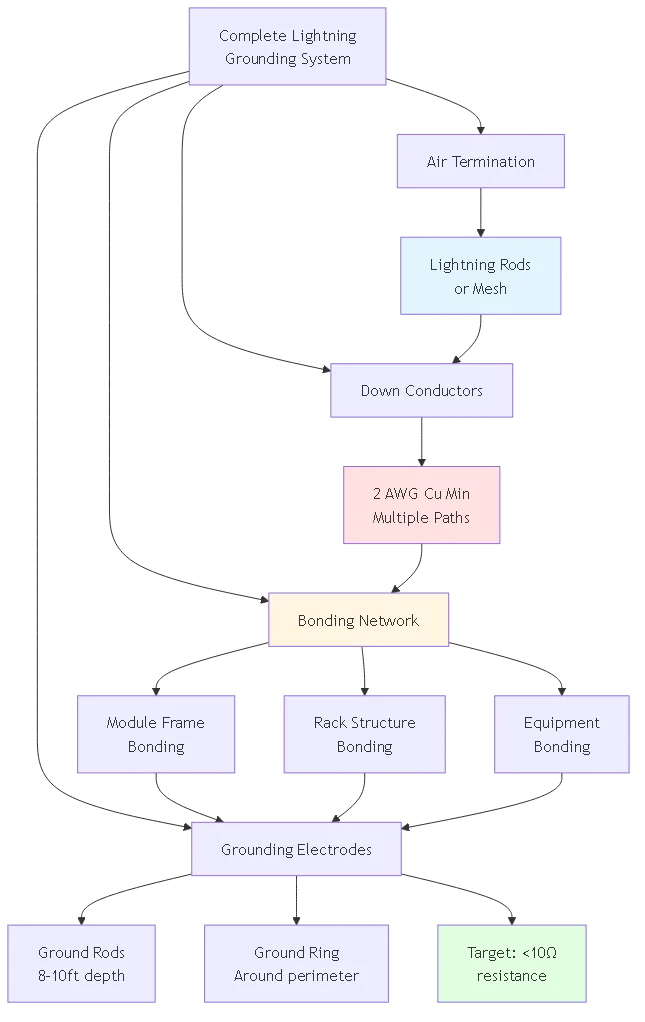

Lightning protection grounding for solar installations represents one of the most critical yet frequently misunderstood aspects of PV system safety. While air termination systems capture lightning strikes and down conductors route current safely downward, the grounding system provides the essential final step: dissipating millions of amperes of lightning energy into the earth without creating dangerous voltage rises that damage equipment or injure personnel.

NFPA lightning protection standards require grounding system resistance below 10Ω for commercial installations, yet field studies show 35-40% of solar systems exceed this threshold due to improper installation techniques, inadequate electrode depth, or insufficient conductor sizing. The consequences extend beyond failed inspections: high-resistance grounding systems cause ground potential rise (GPR) during strikes, creating voltage differences exceeding 10,000V between equipment and earth—enough to arc through inverter cases, destroy monitoring equipment, and shock maintenance personnel.

This installation guide explains proper grounding methods specifically for solar panel lightning protection. You’ll learn equipment grounding conductor (EGC) sizing calculations per NEC 690, bonding jumper installation requirements, ground rod placement for optimal soil contact, grounding ring design for large arrays, and testing procedures verifying completed installations meet resistance targets. Whether installing residential rooftop systems or utility-scale ground-mount arrays, proper grounding installation protects both equipment and lives.

💡 Critical Insight: Lightning grounding differs fundamentally from electrical system grounding—the two serve different purposes and often require separate electrodes. Connecting lightning protection grounding to electrical service grounding without proper bonding can create dangerous circulating currents during storms.

Lightning protection grounding serves three critical functions distinct from traditional electrical system grounding required by NEC Article 250.

Energy dissipation: Lightning strikes deliver 20,000-200,000 amperes in microsecond pulses. This energy must dissipate into earth through electrodes with sufficient surface area to prevent dangerous voltage rises. Unlike steady-state electrical grounding handling milliamps of fault current, lightning grounding handles massive transient currents.

Voltage gradient control: During lightning discharge, earth near the grounding point experiences voltage gradients—voltage differences per distance. Improperly designed systems create “step potentials” where a person’s feet contact earth at different voltages, causing shock even without touching equipment. Proper grounding spreads current across wide electrode areas, reducing gradients below dangerous thresholds (<1000v per meter).Reference potential establishment: All metallic systems—PV module frames, racking, electrical equipment—must bond to common grounding reference. This prevents voltage differences between components during strikes. A floating module frame 5 meters from grounded racking can develop 50,000V potential difference during nearby strike, arcing to racking and igniting fires.

NEC Article 250 electrical grounding: Protects against electrical faults, limits voltage to ground, provides path for fault current to trip breakers. Optimized for 60Hz AC at steady-state amperage. Typical conductor size: 6-4 AWG copper.

NFPA 780 lightning grounding: Handles impulse currents at microsecond timescales, dissipates massive energy, controls transient voltages. Requires larger conductors for surge impedance matching. Minimum conductor size: 2 AWG copper or 1/0 AWG aluminum.

Key difference: Electrical grounding uses thin conductors adequate for steady current but high impedance at lightning frequencies. Lightning grounding needs physically large conductors providing low inductance paths for fast-rising currents.

Critical variable: Soil resistivity (measured in ohm-meters, Ω⋅m) determines how easily earth conducts electricity. Low resistivity = good conductor, high resistivity = poor conductor.

Typical values:

– Wet clay, ocean water: 10-50 Ω⋅m (excellent)

– Moist soil, loam: 50-200 Ω⋅m (good)

– Dry sandy soil: 200-1000 Ω⋅m (poor)

– Solid bedrock: 1000-10,000 Ω⋅m (very poor)

Impact on grounding design: Systems in wet clay may achieve 5Ω resistance with two 8-foot ground rods. Same system in dry sand requires ten 10-foot rods in parallel configuration to reach 10Ω target.

Measurement requirement: Professional grounding design requires soil resistivity testing using 4-point fall-of-potential method or Wenner array. Surface resistance meters provide quick field verification but not detailed soil analysis.

The equipment grounding conductor (EGC) connects PV system metallic components to grounding electrodes. Proper sizing ensures conductor survives lightning current without vaporization.

Minimum size: NEC 690.43 requires EGC no smaller than conductors supplying equipment, with absolute minimum:

– Residential systems (<10kW): 6 AWG copper minimum

- Commercial systems (10-100kW): 4 AWG copper minimum

- Utility systems (>100kW): 2 AWG copper minimum

Lightning protection addition: NFPA 780 requires separate lightning protection grounding conductors (LPGC) sized larger than NEC minimums:

– Air termination down conductors: 2 AWG copper, 1/0 AWG aluminum minimum

– Bonding conductors: 6 AWG copper minimum

– Grounding electrode conductors: 2 AWG copper, 1/0 aluminum minimum

Common mistake: Selecting conductor size based on ampacity tables. Lightning current duration (microseconds) prevents thermal heating that determines ampacity ratings.

Correct approach: Size for mechanical strength and inductance. Physically larger conductors have lower inductance, presenting less impedance to fast-rising lightning currents.

Practical guideline: Use conductors at least two sizes larger than NEC electrical grounding minimums for combined lightning/electrical grounding systems.

Stranded conductors: Preferred for lightning protection. Multiple thin strands provide greater surface area than solid conductor of equivalent cross-section. At lightning frequencies (MHz range), current flows primarily on conductor surface (skin effect).

Solid conductors: Acceptable but less efficient. Single solid conductor has less surface area than stranded equivalent, increasing AC impedance.

Recommendation: Use Class B or Class C stranded copper for all lightning grounding conductors. Reserve solid conductors for short bonding jumpers where flexibility isn’t needed.

Direct path requirement: Lightning current seeks low-impedance path. Route grounding conductors in straight lines avoiding unnecessary bends. Each 90° bend adds inductance equivalent to several feet of straight conductor.

Physical protection: Protect conductors in areas subject to damage:

– Rigid metal conduit for below-grade sections in trafficked areas

– PVC conduit acceptable for residential installations (non-metallic = non-conductive)

– Surface-mount conductors >6 feet above grade can run exposed with cable staples

Prohibition against sharp bends: Never create sharp (<45°) bends in lightning conductors. High-frequency lightning current concentrates at sharp corners, creating hot spots that can melt conductors. Use gradual curves with minimum 8-inch radius.

| Systemgröße | NEC 690 Minimum EGC | NFPA 780 Lightning GC | Recommended Combined |

|---|---|---|---|

| Wohnen <10kW | 6 AWG Cu | 2 AWG Cu | 2 AWG Cu stranded |

| Commercial 10-100kW | 4 AWG Cu | 2 AWG Cu | 1/0 AWG Cu stranded |

| Utility >100kW | 2 AWG Cu | 1/0 AWG Cu | 2/0 AWG Cu stranded |

🎯 Profi-Tipp: When in doubt, size up—larger grounding conductors cost $1-3 per foot more but provide insurance against lightning damage costing thousands. The incremental material cost is negligible compared to total system investment.

Ground rods (also called grounding electrodes) provide the physical earth contact points for dissipating lightning energy. Proper installation maximizes electrode-to-soil contact area.

Material and dimensions:

– Copper-bonded steel: 5/8″ or 3/4″ diameter, 8-10 feet length (most common)

– Solid copper: 1/2″ diameter minimum, 8 feet length (coastal/corrosive environments)

– Galvanized steel: Not recommended for lightning protection (corrosion accelerates with transient currents)

Why copper-bonded: Steel core provides mechanical strength for driving into soil. Copper bonding layer (minimum 10 mils thickness) provides corrosion resistance and low-resistance earth contact.

Length rationale: 8-foot minimum depth reaches below frost line in most climates and accesses moist soil strata. Longer rods (10-12 feet) improve performance in dry or rocky soil.

Equipment required:

– Rotary hammer drill with ground rod driving adapter

– Manual post driver (backup for shallow depths)

– Ground rod marked with depth indicators

– Safety glasses and hearing protection

Verfahren:

Step 1: Select installation location

Position rods per NFPA 780 requirements:

– Minimum 6 feet from building foundation (prevents structural moisture issues)

– Minimum 8 feet from underground utilities (call 811 before digging)

– Minimum 10 feet spacing between multiple rods (prevents overlapping resistance spheres)

Step 2: Begin driving rod

Insert rotary hammer adapter onto rod top. Start drill at low speed to establish vertical alignment. Check plumb with level after first 12 inches. Correct angle errors early—impossible to straighten once rod reaches 3+ feet depth.

Step 3: Drive to full depth

Continue driving until rod top is 2-4 inches below final grade. This prevents trip hazard and positions connection point below surface for protection. If rod encounters rock before reaching 8 feet, do NOT bend rod attempting to bypass—this creates high-resistance connection. Install additional rod 10 feet away and connect in parallel.

Step 4: Attach grounding conductor

Use bronze or copper-bonded clamp rated for direct burial. Exothermic weld (Cadweld) provides optimal connection but requires training. Bolted clamps are acceptable if:

– Two bolts minimum per connection

– Star washers under each bolt penetrate any oxidation

– Anti-oxidant compound applied to all metal-to-metal interfaces

– Torqued to manufacturer specification (typically 15-20 ft-lbs)

Step 5: Backfill and compact

Fill excavation around rod with native soil. Avoid rocks in direct contact with rod—these create air gaps reducing effective contact area. Compact backfill in 6-inch lifts preventing future settlement. At surface, slope grade away from rod to shed water (improves resistance).

When single rod insufficient: Soil resistivity above 200 Ω⋅m typically requires multiple rods in parallel to achieve <10Ω target.Spacing rule: Rods must be spaced ≥2× their length for independence. Two 8-foot rods require ≥16-foot separation. Closer spacing causes resistance spheres to overlap, reducing effectiveness.

Expected resistance reduction:

– Single 8-foot rod in 100 Ω⋅m soil: ~25Ω

– Two rods 16 feet apart: ~15Ω (40% reduction, not 50% due to overlap)

– Four rods in square pattern: ~9Ω (64% reduction)

Connection method: Run bare copper conductor in shallow trench (12-18 inches depth) connecting all rod tops. Use same clamp method as primary grounding conductor. This buried conductor becomes part of grounding electrode system, providing additional earth contact.

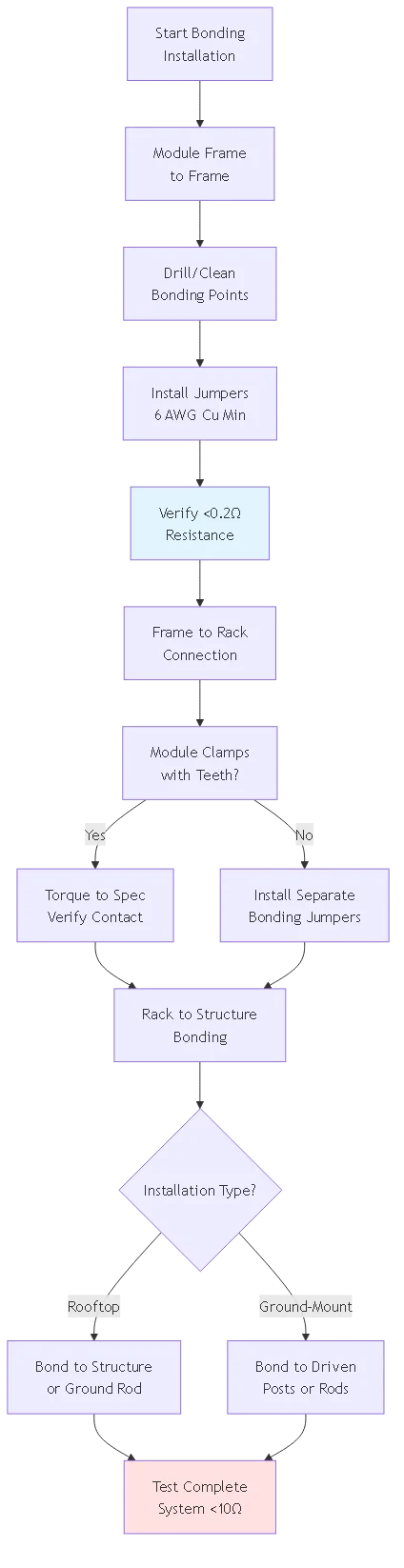

Bonding connects all metallic PV components to establish equipotential—preventing voltage differences between components during lightning strikes. Unbonded frames can develop 50,000V+ potentials relative to grounded equipment.

Zweck: Create electrical continuity across entire array. Each module frame must connect to adjacent frames with measured resistance <0.2Ω between any two points.Bonding jumper specification:

– Minimum size: 6 AWG copper, 4 AWG aluminum

– Type: Stranded for flexibility (thermal expansion/contraction)

– Insulation: THWN-2 or bare copper (if protected from mechanical damage)

– Length: Keep ≤18 inches to minimize inductance

Installation method:

Step 1: Identify bonding points

Module frames typically provide factory-drilled bonding holes. If absent, use self-drilling/tapping screws with star washer penetrating anodizing or coating. Never rely on friction contact between painted/anodized surfaces—insulating coatings prevent electrical continuity.

Step 2: Prepare bonding lugs

Strip 1/2 inch insulation from bonding jumper ends. Insert into compression lug rated for conductor size. Crimp using hex die crimper (not pliers—insufficient pressure). Two-hole lugs provide redundant mechanical connection.

Step 3: Attach to module frames

Position lug against frame at bonding hole. Insert stainless steel bolt (3/8″ or 1/4″ diameter) through lug hole and frame hole. Place star washer under bolt head—sharp teeth bite through coatings establishing metal-to-metal contact. Torque to 7-9 N⋅m (60-80 in-lbs). Apply anti-oxidant compound before assembly in coastal/industrial environments.

Step 4: Verify continuity

Use digital multimeter (DMM) measuring resistance between distant frames. Reading >0.2Ω indicates poor connection—disassemble, clean surfaces, and reassemble. Common causes: painted surfaces not penetrated, missing star washer, insufficient torque.

Racking provides main current path to ground electrodes. Module frames must bond to racking rails with same low-resistance requirements.

Bonding methods:

Method 1: Module clamps with bonding teeth

Many modern clamps include serrated teeth that penetrate module frame and rail during tightening. Verify teeth contact unpainted metal on both surfaces. Torque clamps per manufacturer specification ensuring teeth bite fully into metal.

Method 2: Separate bonding jumpers

If clamps lack bonding features, install dedicated jumpers:

– Connect from module frame bonding point to rail bonding hole

– Use same lug/bolt/washer method as frame-to-frame bonding

– Install one jumper per module or every other module (system designer specifies based on fault current calculations)

Method 3: Factory-bonded systems

Some racking systems provide integrated bonding—module weight on specialized clamps creates bonded connection. These require manufacturer certification documenting resistance measurements. Field verification still required—don’t trust marketing claims without data.

Final link: Racking system must bond to building structure (rooftop) or ground electrodes (ground-mount). This completes path from lightning strike (captured by air termination) through module frames and racking to earth.

Rooftop installations:

Install bonding conductor from primary racking attachment point to:

– Building structural steel (if electrically continuous and grounded)

– Dedicated roof-mounted ground electrode (if structure is non-conductive)

– Down-conductor connection point for lightning protection system

Use 2 AWG minimum bonding conductor. Route in straight line avoiding sharp bends. Protect from mechanical damage in foot traffic areas.

Ground-mount installations:

Racking posts driven into earth provide natural grounding if:

– Post material is conductive (steel, not fiberglass)

– Posts extend 4+ feet into soil contacting earth

– Soil resistivity is reasonable (<500 Ω⋅m)

Verify with resistance measurement. If posts alone don’t achieve <10Ω, install supplemental ground rods at perimeter and bond to racking.

Arrays exceeding 50kW benefit from grounding ring (also called ground loop)—buried conductor encircling the array perimeter. This provides multiple earth contact points and reduces ground impedance.

Concept: Rather than discrete point contacts (ground rods), ring conductor provides continuous earth contact around entire array perimeter. Total contact area far exceeds individual rods, dramatically reducing resistance.

Effectiveness: Properly installed grounding ring achieves 3-6Ω resistance in most soil conditions—below 10Ω target without supplemental rods. Poor soil may require enhancement with chemical ground rods or bentonite treatment.

Minimum size: 2 AWG copper or 1/0 AWG aluminum bare conductor.

Material consideration: Bare copper resists corrosion in most soils. Some corrosive environments (high sulfur content, industrial contamination) require tinned copper or aluminum with anti-corrosion coating.

Physical properties: Stranded conductor conforms to trench irregularities better than solid. Flexibility accommodates differential settlement and thermal expansion.

Step 1: Layout and excavation

Mark ring perimeter 3-6 feet outside array footprint. This distance ensures ring extends beyond structure’s “shadow,” accessing undisturbed soil. Excavate trench 18-30 inches deep, 6 inches wide. Deeper burial accesses moist soil strata and protects conductor from frost heave.

Step 2: Trench preparation

Remove rocks >2 inches from trench bottom—rocks create air gaps reducing earth contact. If soil is dry (resistivity >200 Ω⋅m), consider enhancement:

– Line trench with bentonite clay (swells when wet, maintains moisture)

– Install conductive concrete (specialized mix with ground carbon)

– Use chemical ground rods at 20-foot intervals along ring

Step 3: Conductor installation

Unroll conductor into trench avoiding kinks or sharp bends. Support conductor on 2-inch layer of fine soil (no rocks). At corners, maintain minimum 8-inch radius bends—sharp corners increase impedance. Where conductor must cross under walkways or roads, encase in PVC conduit for mechanical protection.

Step 4: Ground rod connections

Install ground rods at ring corners and mid-points of long runs (≤50 feet spacing). Connect rods to ring conductor using exothermic weld or compression clamp. These rods supplement ring, providing redundancy and lowering overall resistance.

Step 5: Bonding conductor attachments

Bring bonding conductors from array racking to ring at multiple points (minimum 4 for arrays <100kW, additional points every 30m of perimeter for larger arrays). Connect using: - Exothermic weld (optimal—homogeneous connection) - Irreversible compression connectors (good—mechanical cold weld) - Bolted split-bolt connectors with anti-oxidant (acceptable—requires periodic inspection)

Step 6: Testing before backfill

Critical: Test ring resistance BEFORE backfilling. Correcting resistance issues after burial requires excavation. Use clamp-on ground tester or fall-of-potential method. Target: <8Ω for ring alone, <6Ω after connecting rods.

Step 7: Backfill and compaction

Cover conductor with 6 inches of fine soil (screened to remove rocks >1/2 inch). This creates intimate contact between conductor and earth. Compact lightly—don’t stress conductor. Add warning tape 6 inches below final grade marking buried conductor location. Complete backfill to original grade, compacting in lifts to prevent settlement.

⚠️ Wichtig: Document ring location with GPS coordinates and buried depth. Years later, excavation for repairs or expansion requires this information to avoid damaging grounding system.

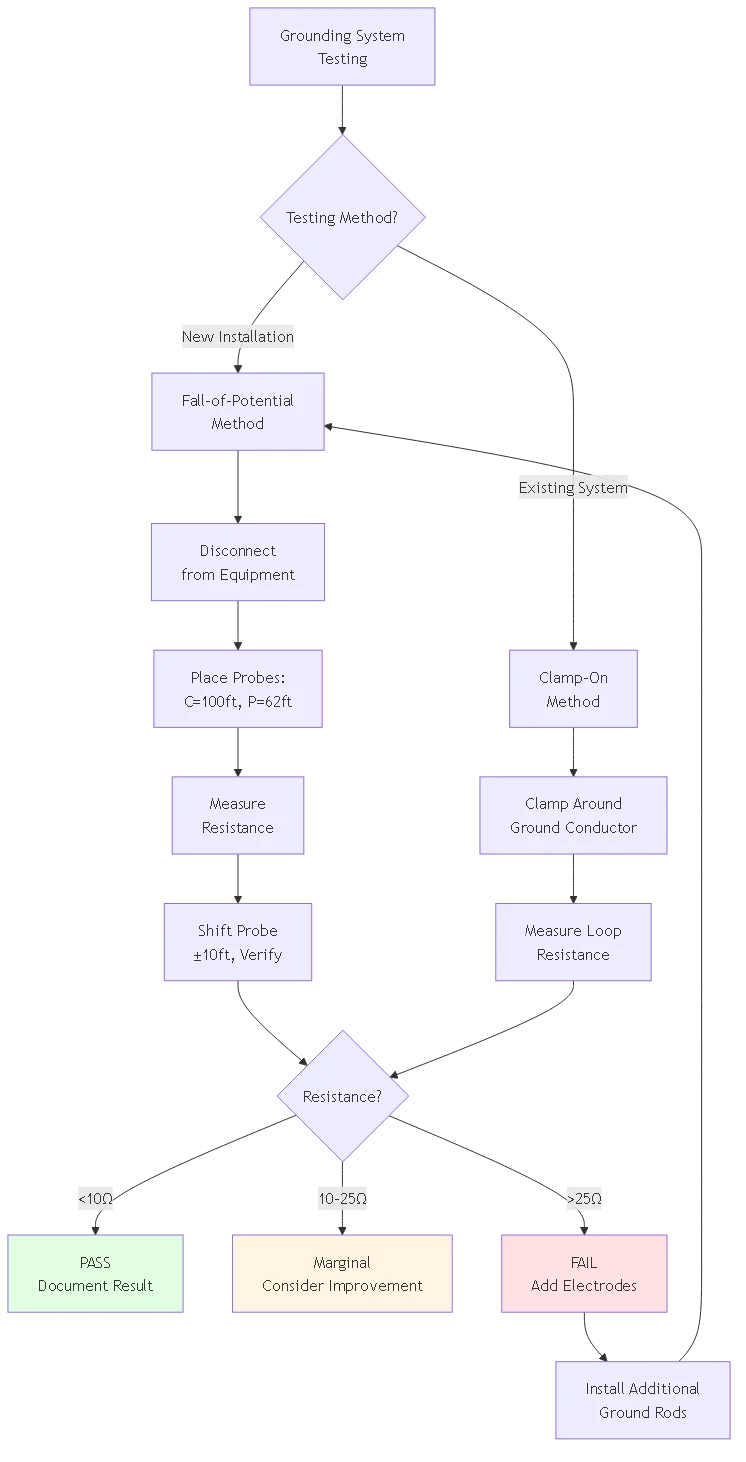

Installation quality determines grounding effectiveness. Proper testing verifies completed system meets resistance targets and NEC/NFPA requirements.

Most accurate field method for measuring grounding resistance. Requires specialized earth ground tester (Megger, Fluke, or equivalent).

Equipment setup:

– Ground tester with three terminals (X, P, C)

– Two test probes (current probe and potential probe)

– 200 feet of test wire

– Hammer for driving test probes

Verfahren:

Step 1: Disconnect grounding system

Temporarily disconnect grounding electrode system from PV equipment. This isolates system under test from parallel paths that would give false low readings.

Step 2: Probe placement

Drive current probe (C) 100 feet from grounding electrode in straight line. Drive potential probe (P) at 62% distance (62 feet from electrode, 38 feet from current probe). This 62% distance eliminates mutual coupling effects between electrode and probes.

Step 3: Connect tester

Connect tester X terminal to grounding electrode. Connect P terminal to potential probe. Connect C terminal to current probe. Verify connections are tight—resistance in test leads corrupts readings.

Step 4: Perform measurement

Activate tester. Modern instruments inject test current and measure resulting voltage, calculating resistance automatically. Reading should stabilize within 10-20 seconds. Record result.

Step 5: Verify with probe position shift

Move potential probe 10% closer (to 52% position) and re-measure. Then move 10% farther (to 72% position) and measure again. Three readings should agree within 10%. If not, current probe is too close—extend to 150 feet and repeat.

Step 6: Interpret results

– <5Ω: Excellent grounding - 5-10Ω: Acceptable for most applications - 10-25Ω: Marginal—meets NEC minimum but consider improvements - >25Ω: Inadequate—supplemental electrodes required

Faster method for installed systems where fall-of-potential testing is impractical (system can’t be disconnected, limited space prevents probe placement).

Limitation: Requires closed loop in grounding system (ground ring or multiple rods connected). Won’t work for single isolated ground rod.

Verfahren:

Place clamp-on tester around grounding conductor. Tester injects signal into conductor and measures loop resistance. Result approximates true ground resistance if system has multiple parallel paths to earth. Less accurate than fall-of-potential but useful for quick field verification and periodic monitoring.

Initial installation: Test before energization and before burying conductors. Document baseline resistance.

Annual testing: Re-test yearly during maintenance. Compare to baseline—increase >20% indicates degradation (corrosion, loose connections, soil moisture changes).

Post-lightning strike: Always test after known lightning hits. Strike current can vaporize connections or damage electrodes. Degraded grounding won’t protect against next strike.

After soil disturbance: Construction, landscaping, or erosion near grounding system changes soil contact. Test verifies integrity maintained.

| Resistance Range | Performance | Action Required |

|---|---|---|

| <5Ω | Ausgezeichnet | None—meets all standards |

| 5-10Ω | Gut | Acceptable—document |

| 10-15Ω | Marginal | Meets NEC minimum, monitor |

| 15-25Ω | Poor | Add supplemental electrodes |

| >25Ω | Inadequate | Remediation required—fails inspection |

Problem: Installing 6-foot ground rods instead of code-required 8-foot minimum, or stopping when rod hits shallow rock layer. Inadequate depth reduces earth contact area, increasing resistance.

Common scenarios:

– Using residential-grade 6-foot rods for commercial installations

– Angling rod when hitting rock rather than relocating

– Counting rod above grade as meeting depth requirement

Berichtigung: Use 8-foot minimum rods, 10-foot preferred in dry soil. If rock prevents full depth, relocate rod or install multiple shorter rods in parallel. Never angle rods >15° from vertical—dramatically reduces effectiveness.

Problem: Relying on friction contact between painted/anodized surfaces, missing star washers, or inadequate torque. Results in high-resistance connections that arc during lightning strikes.

Common scenarios:

– Bolting lugs to painted module frames without penetrating coating

– Using flat washers instead of star washers

– Hand-tightening instead of torquing to specification

– No anti-oxidant compound in corrosive environments

Berichtigung: Use star washers on every bonding connection. Torque to 7-9 N⋅m for module frame connections, 15-20 N⋅m for ground rod clamps. Apply anti-oxidant compound at all copper-aluminum and outdoor connections.

Problem: Direct contact between copper and aluminum creates galvanic cell, corroding connection and increasing resistance. Occurs in bonding jumpers, lugs, and ground clamps.

Common scenarios:

– Copper bonding conductor in aluminum clamp

– Aluminum module frame bonded with copper lug (no barrier)

– Steel bolts connecting copper components

Berichtigung: Use compatible metals (copper-to-copper, aluminum-to-aluminum) or approved bimetallic connectors. Apply anti-oxidant compound designed for dissimilar metal connections. Use stainless steel fasteners—neutral to both copper and aluminum.

Problem: 90° or sharper bends dramatically increase impedance at lightning frequencies. High-frequency current concentrates at bends, creating hot spots that can melt conductor.

Common scenarios:

– Right-angle turns at building corners

– Tight bends around obstacles

– Looping excess conductor instead of trimming

Berichtigung: Maintain minimum 8-inch radius on all bends. Use gradual sweeping turns rather than sharp angles. If space limited, use two 45° bends instead of single 90° bend.

Problem: Directly bonding lightning protection ground to electrical service ground without proper isolation creates circulating currents during storms, potentially damaging sensitive electronics.

Common scenarios:

– Connecting down conductor to service entrance ground rod

– Using building foundation Ufer ground for lightning protection

– Single ground rod serving both lightning and electrical systems

Berichtigung: Install separate lightning protection grounding system per NFPA 780. Bond the two systems together with 6 AWG minimum conductor, but maintain physical separation (10+ feet) between electrodes. This allows potential equalization while preventing circulating currents in electrical system.

When testing reveals resistance above target values, systematic troubleshooting identifies causes and solutions.

Test individual electrodes: If multiple rods in parallel show high combined resistance, test each rod individually. This identifies whether all rods have high resistance (soil issue) or one rod has poor connection (installation issue).

Check connections: Resistance >25Ω with properly installed electrodes usually indicates connection problems. Disassemble each clamp/lug, clean surfaces with wire brush, apply anti-oxidant, and reassemble with proper torque.

Verify electrode depth: Confirm rods reach full 8+ feet depth. Shallow rods in dry surface soil have 2-5× higher resistance than deep rods in moist substrata.

Assess soil conditions: Recent drought dramatically increases soil resistivity. Wet soil after rain gives misleadingly low readings. Test during typical moisture conditions, not extreme wet/dry.

Add parallel ground rods: Most effective solution. Each additional rod in parallel reduces total resistance. Space rods ≥2× rod length apart for independence. Four rods typically achieve <10Ω in all but worst soil.Increase rod depth: If soil improves at depth (bedrock at surface, moist clay below), drive longer rods (10-12 feet) or use augered holes with backfill. Some commercial systems use 20-foot deep-driven electrodes.

Install grounding ring: For large arrays where multiple rods still inadequate, grounding ring provides extensive earth contact. Ring alone often achieves 3-6Ω in moderate soil.

Chemical treatment: Last resort for truly poor soil (solid rock, very dry sand). Options:

– Bentonite clay backfill around rods (absorbs moisture, maintains conductivity)

– Conductive concrete (specialized mix with carbon additives)

– Chemical ground rods (hollow rods filled with electrolytic salts that leach into soil)

Cost considerations: Two additional ground rods cost $100-200 installed. Chemical treatments cost $500-1500 per electrode. Design for adequate electrodes initially—retrofitting costs 3-5× more than installing correctly first time.

Proper documentation proves code compliance and provides maintenance baseline for system lifetime.

Grounding system drawings: As-built plans showing:

– Ground rod locations with GPS coordinates

– Grounding ring route (if installed)

– Bonding conductor paths

– Connection point locations

– Electrode depths and spacing

Test reports: Document including:

– Test method used (fall-of-potential, clamp-on)

– Individual electrode resistances

– Combined system resistance

– Test date and weather conditions

– Tester equipment model and calibration date

Material certifications: Listing documentation for:

– Ground rods (UL 467)

– Bonding conductors (UL 854)

– Clamps and lugs (UL 467)

– Anti-oxidant compound (UL listing)

Fotos der Installation: Visual record of:

– Ground rod driving (showing depth achieved)

– Bonding connections before burial

– Grounding ring installation in trench

– Final completed system

Most jurisdictions require grounding system inspection before energization. Inspector verifies:

– Ground rod depth meets NEC 250.53(G) (8 feet minimum)

– Conductor sizing meets NEC 690.43 minimums

– Bonding connections have star washers and proper torque

– Grounding resistance meets NEC 250.56 (<25Ω) and preferably NFPA 780 (<10Ω)

Inspection timing: Request inspection after grounding installation but BEFORE backfilling conductors. Inspector must see buried work before covering. Schedule before pouring concrete or final grading.

Ground rods must be driven to minimum 8-foot depth per NEC 250.53(G), with top of rod 2-4 inches below final grade. This depth ensures electrodes reach below frost line and access moist soil strata providing lower resistivity. In dry or rocky soil, 10-foot rods provide better performance—the additional 25% depth often reduces resistance 30-40% compared to 8-foot rods. If rock prevents full depth insertion, NEC allows supplemental lateral grounding electrode within 6 inches of rod, but this is less effective than proper depth. Alternatively, relocate rod to soil location permitting full depth, or install multiple rods in parallel configuration. Never cut rods shorter than 8 feet—this violates code and dramatically reduces grounding effectiveness. Coastal and high-lightning areas should use 10-foot minimum for enhanced protection margin. Document actual depth achieved for each rod in as-built drawings—inspectors often verify compliance and this information is essential for future system maintenance or expansion.

Lightning protection grounding conductors must be minimum 2 AWG copper or 1/0 AWG aluminum per NFPA 780 standards—substantially larger than NEC electrical grounding minimums. This sizing reflects the different requirements: lightning involves massive transient currents at high frequencies requiring low inductance, while electrical grounding handles steady-state fault currents where ampacity determines size. For combined lightning/electrical grounding (common in PV systems), use conductors meeting the larger lightning protection requirements: 2 AWG copper minimum for residential (<10kW), 1/0 AWG for commercial (10-100kW), and 2/0 AWG for utility systems (>100kW). Stranded conductors preferred over solid for lower AC impedance and better flexibility. Module frame bonding jumpers can be smaller—6 AWG copper minimum—but main down conductors and grounding electrode conductors require full lightning-rated sizing. When in doubt, size up—the cost difference between 2 AWG and 1/0 AWG is $1-2 per foot but provides significant safety margin.

No—electrical system grounding and lightning protection grounding should be separate systems that are bonded together, not the same system. NEC 250 electrical grounding optimizes for 60Hz AC fault currents at ampere levels, using smaller conductors and single ground rod often sufficient. Lightning protection per NFPA 780 handles microsecond transients at 20,000-200,000 amperes requiring larger conductors and multiple electrodes. Attempting to use electrical service ground for lightning protection risks: inadequate conductor size causing vaporization during strikes, single electrode unable to dissipate lightning energy (voltage rise damages equipment), and circulating currents in electrical system damaging sensitive electronics. Correct approach: install dedicated lightning protection grounding system with multiple electrodes and large conductors, then bond it to electrical system ground using 6 AWG minimum conductor. This maintains potential equalization (preventing arcing between systems) while keeping lightning current primarily in lightning protection conductors rather than electrical wiring. Physical electrode separation (10+ feet) prevents resistance spheres overlapping while bonding equalizes voltage.

Test grounding system resistance annually at minimum, preferably during seasonal maintenance when weather conditions match system operating environment (not immediately after rain giving falsely low readings). Initial baseline test during commissioning provides reference for comparison—resistance increasing >20% from baseline indicates degradation requiring investigation. Additional testing required: after any known lightning strikes (current can damage connections or vaporize conductor sections), after construction or landscaping disturbing soil near grounding electrodes (changes soil compaction and moisture), and if monitoring systems show abnormal ground fault occurrences (may indicate compromised grounding). Commercial and utility-scale installations should test semi-annually due to higher lightning exposure and greater equipment value at risk. Testing costs $200-500 for professional service on residential systems, $500-1500 commercial—small price compared to equipment replacement after lightning damage. Document all test results with date, method used, weather conditions, and individual electrode measurements if testing parallel rod systems. Many insurance policies require documented annual testing to maintain coverage.

High ground resistance (>10-25Ω) typically results from four causes. First, inadequate electrode depth—rods not reaching moist soil strata provide poor earth contact. Solution: drive rods to full 8-10 foot depth, or install deeper electrodes if shallow bedrock prevents standard depth. Second, poor soil conductivity—dry sandy soil, gravel, or solid rock have resistivity 500-10,000 Ω⋅m versus 50-200 Ω⋅m for normal soil. Solution: install multiple parallel ground rods spaced 2× rod length apart, or add grounding ring encircling array. Third, failed connections—corroded clamps, missing star washers, or inadequate torque create high resistance at connection points. Solution: disassemble all connections, clean with wire brush, apply anti-oxidant, reassemble with proper torque. Fourth, seasonal soil moisture variation—resistance doubles or triples during drought as soil dries. Solution: test during typical moisture conditions and design system with margin. For persistently high resistance despite these fixes, consider chemical enhancement: bentonite clay backfill around rods maintains moisture ($50-100 per rod), or chemical ground rods release electrolytic salts into soil ($200-400 per electrode). Multiple rods in parallel most cost-effective solution in most scenarios.

Yes and no—they should be separate systems with independent electrodes but bonded together at one point. NEC 250.50 requires all grounding electrodes on a premises to be bonded together, preventing dangerous voltage differences between systems during electrical events. However, NFPA 780 lightning protection requires its own dedicated electrodes and conductors sized for lightning currents, not electrical fault currents. Correct implementation: install lightning protection ground rods at locations calculated by air termination design (typically building corners and array perimeter), using 2 AWG minimum conductors. Install separate electrical system ground per NEC Article 250 at service entrance. Then bond the two systems together using 6 AWG copper bonding jumper, but maintain 10+ feet physical separation between electrode groups. This separation prevents lightning current from flowing through electrical system conductors (which aren’t sized for it), while bonding equalizes voltage preventing destructive arcing between systems. Some installers attempt to save money using single common ground—this violates NFPA 780, creates code compliance issues, and risks equipment damage from circulating currents. Proper separation with bonding costs $100-300 more but provides correct protection and inspector approval.

Ground potential rise (GPR) occurs when large current flows into limited earth connection, raising local ground voltage above remote earth reference. During lightning strike, 100,000 amperes flowing into 10Ω grounding electrode creates 1,000,000 volt (1MV) instantaneous rise in local ground potential. This matters because equipment connected to that grounding system rises to this voltage relative to remote ground, while other systems remain at true ground. Voltage differences between systems cause arcing, destroying electronics and creating shock hazards. Example: Lightning strikes array, current flows to grounding electrode creating 50,000V GPR. Building electrical system 100 feet away remains at true ground (0V). Voltage difference arcs through inverter connected to both systems, destroying it. Prevention requires: low grounding resistance reducing voltage rise (5Ω resistance yields 500,000V vs 1MV—still high but shorter duration), multiple distributed electrodes spreading current (reduces voltage rise per electrode), and bonding all systems together (equalizes voltage—no arc even if all systems rise together). This is why grounding ring is superior to single ground rod for lightning protection—distributed contact reduces peak voltage rise during strikes. GPR also creates dangerous step potentials near grounding electrodes—personnel should avoid areas within 10 feet of ground rods during thunderstorms.

Proper lightning protection grounding for solar installations requires understanding fundamentally different requirements than electrical system grounding. The massive transient currents, microsecond rise times, and distributed nature of PV arrays demand larger conductors, multiple parallel electrodes, low-inductance connections, and comprehensive bonding networks that may seem over-engineered compared to conventional electrical work.

Wichtigste Erkenntnisse:

1. Use lightning-rated conductor sizes—2 AWG copper minimum for down conductors and grounding electrode conductors, not the smaller NEC electrical grounding minimums. Lightning frequencies require low inductance, achieved through physically large conductors.

2. Ground rods must reach 8-10 feet depth—shallow rods in dry surface soil have 3-5× higher resistance than properly deep rods accessing moist substrata. Multiple parallel rods further reduce resistance when single rod insufficient.

3. Bonding requires metal-to-metal contact—star washers penetrating coatings, proper torque (7-9 N⋅m module frames, 15-20 N⋅m ground clamps), and anti-oxidant compound at outdoor connections. Painted/anodized friction contact provides inadequate conductivity.

4. Ziel <10Ω grounding resistance—NEC allows 25Ω but lightning protection requires lower resistance for effective energy dissipation and voltage gradient control. Test using fall-of-potential method before and after backfilling.

5. Separate but bonded grounding systems—lightning protection and electrical grounding serve different purposes requiring independent electrodes with different locations and conductor sizes, but must bond together preventing voltage differences between systems.

Investment in proper grounding installation—quality materials ($500-2000 residential, $2000-8000 commercial), professional testing ($200-500), and correct procedures—costs far less than lightning damage typically exceeding $10,000 residential, $50,000+ commercial. The grounding system functions silently in background until the moment lightning strikes, then determines whether the event causes minor inconvenience or catastrophic equipment destruction and potential injuries.

Related Resources:

– Lightning Protection Air Termination Design

– DC SPD Selection for Surge Protection

– Solar PV System Protection Best Practices

Ready to design compliant lightning protection grounding for your solar installation? Contact our grounding engineering team for soil resistivity testing, grounding system design calculations, material specifications, and installation supervision. We provide turnkey grounding solutions from site assessment through final resistance testing and documentation for building authority approval and insurance certification.

Zuletzt aktualisiert: March 2026

Autor: SYNODE Technisches Team

Rezensiert von: Lightning Protection Engineering Department

Schwerpunkt Stichwort: solar panel lightning protection

URL Slug: how-to-install-solar-panel-lightning-protection-grounding

Meta-Titel: How to Install Solar Panel Lightning Protection: Grounding Methods

Meta-Beschreibung: Learn how to install solar panel lightning protection: equipment grounding conductor sizing, bonding jumpers, ground rod installation, grounding ring design, and NEC 690 compliance methods.

Inhaltliche Ebene: Tier 3 (Supporting Content)

Umstellungstrichter: Top of Funnel (Bekanntheit)

Ziel-Wortzahl: 2800-4000 Wörter

Ziel Meerjungfrauen-Diagramme: 3

Bitte konfigurieren Sie diese in den Rank-Math-Einstellungen und löschen Sie dann dieses Feld vor der Veröffentlichung.

Ground rods must be driven to minimum 8-foot depth per NEC 250.53(G), with top of rod 2-4 inches below final grade. This depth ensures electrodes reach below frost line and access moist soil strata providing lower resistivity. In dry or rocky soil, 10-foot rods provide better performance—the additional 25% depth often reduces resistance 30-40% compared to 8-foot rods. If rock prevents full depth insertion, relocate rod or install multiple rods in parallel configuration. Never cut rods shorter than 8 feet—this violates code and dramatically reduces grounding effectiveness.

Lightning protection grounding conductors must be minimum 2 AWG copper or 1/0 AWG aluminum per NFPA 780 standards—substantially larger than NEC electrical grounding minimums. For combined lightning/electrical grounding, use 2 AWG copper minimum for residential (<10kW), 1/0 AWG for commercial (10-100kW), and 2/0 AWG for utility systems (>100kW). Stranded conductors preferred over solid for lower AC impedance. Module frame bonding jumpers can be smaller—6 AWG copper minimum—but main down conductors require full lightning-rated sizing.

No—electrical system grounding and lightning protection grounding should be separate systems that are bonded together. NEC 250 electrical grounding optimizes for 60Hz AC fault currents, while lightning protection per NFPA 780 handles microsecond transients at 20,000-200,000 amperes. Correct approach: install dedicated lightning protection grounding system with multiple electrodes and large conductors, then bond it to electrical system ground using 6 AWG minimum conductor. Physical electrode separation (10+ feet) with bonding maintains potential equalization while preventing circulating currents.

Test grounding system resistance annually at minimum, preferably during seasonal maintenance. Initial baseline test during commissioning provides reference—resistance increasing >20% from baseline indicates degradation. Additional testing required after known lightning strikes, construction disturbing soil near electrodes, or abnormal ground fault occurrences. Commercial installations should test semi-annually. Testing costs $200-500 residential, $500-1500 commercial. Document all test results with date, method, weather conditions, and individual electrode measurements.

High ground resistance (>10-25Ω) results from inadequate electrode depth, poor soil conductivity, failed connections, or seasonal moisture variation. Solutions: drive rods to full 8-10 foot depth, install multiple parallel rods spaced 2× rod length apart, add grounding ring for large arrays, or use chemical enhancement with bentonite clay or electrolytic compounds. Most cost-effective solution is multiple parallel ground rods. Disassemble and clean all connections with wire brush, apply anti-oxidant, and retorque to specification.

Yes—they should be separate systems with independent electrodes but bonded together at one point. NFPA 780 lightning protection requires dedicated electrodes and 2 AWG+ conductors sized for lightning currents. Install separate electrical system ground per NEC Article 250. Bond the two systems using 6 AWG copper jumper with 10+ feet physical separation between electrode groups. This prevents lightning current from flowing through electrical conductors while equalizing voltage to prevent arcing. Common single ground violates NFPA 780 and risks equipment damage.

Ground potential rise (GPR) occurs when large lightning current flows into grounding electrode, raising local ground voltage above remote earth. Example: 100,000 amperes into 10Ω electrode creates 1,000,000 volt instantaneous rise. This matters because voltage differences between grounded systems cause destructive arcing. Prevention requires low grounding resistance (5Ω vs 10Ω halves voltage rise), multiple distributed electrodes spreading current, and bonding all systems together equalizing voltage. Grounding ring superior to single rod for reducing peak GPR during strikes.