Adresse

304 Nord Kardinal

St. Dorchester Center, MA 02124

Arbeitszeiten

Montag bis Freitag: 7AM - 7PM

Am Wochenende: 10AM - 5PM

Adresse

304 Nord Kardinal

St. Dorchester Center, MA 02124

Arbeitszeiten

Montag bis Freitag: 7AM - 7PM

Am Wochenende: 10AM - 5PM

If you’ve ever looked at outdoor electrical installations and wondered about those gray or metal boxes where wires meet, you’re looking at outdoor electrical junction boxes. These weatherproof enclosures are critical safety components in any exterior electrical system, from landscape lighting to pool equipment.

Whether you’re planning to add outdoor outlets, installing solar panels, or upgrading your home’s exterior lighting, understanding outdoor electrical junction boxes is essential. The wrong box or improper installation can lead to electrical failures, code violations, or even fire hazards. NEC (National Electrical Code) Article 314 provides strict requirements for these installations, and for good reason.

This guide breaks down everything homeowners need to know about outdoor electrical junction boxes in plain English. You’ll learn what they are, why they’re required, the difference between junction boxes and distribution boxes, types available (pull boxes vs splice boxes), NEC 314 sizing requirements, and how to choose the right one for your project.

💡 Quick Answer: An outdoor electrical junction box is a weatherproof enclosure where electrical wires connect or split, required by code to protect connections from moisture, provide safe access for maintenance, and prevent electrical hazards in exterior applications.

An outdoor electrical junction box is a weatherproof protective enclosure installed outside buildings where electrical wires meet, connect, or change direction. Think of it as a secure meeting point for electrical wiring that keeps everything safe from rain, snow, dirt, and physical damage.

Outdoor: Designed specifically to withstand weather exposure—rain, snow, sun, temperature extremes, and moisture. Unlike indoor boxes, these are built with sealed gaskets and weather-resistant materials.

Elektrisch: Houses electrical wires, connections, and sometimes devices like switches or outlets. Must be listed for electrical use and meet safety standards.

Junction: A “junction” is where things meet or join together. In electrical terms, it’s where wires connect to each other or to devices—where your electrical pathways intersect.

Box: A protective enclosure that contains and protects the electrical components inside. Provides a physical barrier between connections and the environment.

The outdoor electrical junction box serves several critical safety and functional roles:

1. Protects Wire Connections: Electrical connections are the weakest points in any wiring system. The junction box shields these vulnerable connections from moisture, which could cause shorts, corrosion, or complete failure.

2. Contains Electrical Arcs: If a connection fails or sparks, the junction box contains the arc and prevents it from igniting nearby materials like wood siding or insulation.

3. Provides Access: When you need to troubleshoot, modify, or repair outdoor wiring, the junction box provides a designated, safe access point. NEC requires all connections be accessible—no burying connections in walls or underground.

4. Meets Code Requirements: NEC Article 314 mandates that all electrical connections outside the protective sheathing of cables must be housed in approved boxes. Installing without proper junction boxes is a code violation.

Real-World Analogy: An outdoor electrical junction box is like a waterproof treasure chest for your electrical connections. Just as you wouldn’t leave valuables exposed to rain, you can’t leave electrical connections unprotected outside. The box keeps everything dry, safe, and accessible when needed.

Water and electricity are a dangerous combination. Outdoor electrical junction boxes are specifically rated to prevent moisture infiltration through gaskets, seals, and drainage provisions.

Real Example: Without a proper outdoor junction box, morning dew alone can collect on wire connections, causing corrosion over months. Eventually, this corrosion increases resistance, generates heat, and can lead to connection failure or electrical fire. A weatherproof box with proper NEMA 3R or NEMA 4X rating prevents this entirely.

Outdoor wiring is exposed to lawn equipment, ladders, falling branches, and curious kids. Junction boxes provide a robust barrier that protects wiring from physical damage.

NEC 300.5 requires buried or exposed outdoor wiring to be protected. Junction boxes satisfy this requirement by providing a rigid enclosure that can withstand impacts without exposing energized wires.

Why codes require them: NEC 314.29 specifically requires that junction boxes be installed so that the wiring is accessible without removing permanent building components. This isn’t optional—it’s a legal requirement enforced during electrical inspections.

Installing outdoor wiring without proper junction boxes will fail inspection, may void your homeowner’s insurance, and creates serious liability if an electrical incident occurs. Permits and inspections exist to ensure safety, and junction boxes are a fundamental requirement.

Outdoor electrical needs change over time. You might add landscape lighting, install a hot tub, or upgrade to LED fixtures. Properly installed junction boxes make these modifications straightforward and safe.

Without junction boxes, making changes means cutting into buried wiring or opening walls—expensive and potentially dangerous. Junction boxes provide planned access points for modifications.

Every time electrical wire changes direction, enters or exits conduit, or transitions between different wiring methods, stress is placed on the conductors. Junction boxes provide strain relief and protect wires at these critical transition points.

At their core, outdoor electrical junction boxes are engineered enclosures with several protective features working together to keep electrical connections safe.

#### 1. Weather Sealing: Keeping Moisture Out

What it does: Gaskets, threaded hubs, and tight-fitting covers create a water-resistant barrier around the box opening.

How it works: When you close the box cover, a rubber gasket compresses between the cover and box body, creating a weathertight seal. Conduit entries use threaded hubs with sealing washers that prevent water from entering where conduit meets the box.

Think of it like a high-quality food storage container with a rubber seal—except instead of keeping your leftovers fresh, it’s keeping your electrical connections dry and safe.

#### 2. Material Durability: Withstanding the Elements

What it does: Construction materials resist corrosion, UV degradation, and temperature extremes specific to outdoor exposure.

How it works: Common materials include:

– PVC plastic: Lightweight, corrosion-proof, affordable, resists UV degradation

– Galvanized steel: Strong, impact-resistant, economical but can rust in coastal areas

– Aluminium: Lightweight metal, excellent corrosion resistance, mid-range cost

– Stainless steel: Maximum corrosion resistance for harsh environments, highest cost

#### 3. Secure Wire Connections: Preventing Loosening

What it does: Provides a stable, protected space for wire splices using approved methods like wire nuts, terminal blocks, or push-in connectors.

How it works: The rigid box prevents movement that could loosen connections over time. Properly made connections inside the box won’t experience vibration, temperature cycling, or moisture exposure that degrades the splice.

#### 4. Ground Continuity: Safety Path for Fault Current

What it does: Metal boxes provide a grounding point that connects to the equipment grounding system, creating a safe path for fault currents.

How it works: If a hot wire contacts the metal box, the ground connection allows current to flow back to the panel, tripping the breaker and preventing shock hazard. This is why metal boxes must be bonded to the grounding system.

Many homeowners confuse junction boxes with distribution boxes. While both are enclosures for electrical components, they serve different purposes and have different requirements.

Primary Purpose: Houses wire-to-wire connections (splices) where electrical paths meet or split. No circuit breakers or major distribution points.

Typical Contents:

– Wire splices using wire nuts or terminal blocks

– Pigtail connections for grounding

– Through-wire routing where cables change direction

– Cable transitions (from one type to another)

Size Characteristics: Generally smaller, sized based on wire fill calculations per NEC 314.16. Common sizes range from 4″×4″ to 12″×12″ for residential applications.

Code Focus: NEC Article 314 governs junction boxes with emphasis on box fill calculations, accessibility, and proper support.

Common Applications:

– Landscape lighting wire connections

– Conduit junction points for outdoor circuits

– Pool/spa equipment wire transitions

– Exterior outlet branch circuits

Primary Purpose: Houses circuit breakers, fuses, or major split points where one incoming circuit divides into multiple outgoing circuits.

Typical Contents:

– Circuit breakers or fuses

– Bus bars for power distribution

– Multiple incoming and outgoing circuits

– Sometimes metering equipment

Size Characteristics: Larger enclosures to accommodate breakers and bus work. Typically 12″×12″ to 24″×36″ or larger for commercial applications.

Code Focus: NEC Articles 312 (Cabinets and Cutout Boxes) and 408 (Switchboards and Panelboards) apply, with more stringent requirements for working space and clearances.

Common Applications:

– Pool/spa equipment disconnect panels

– Outdoor subpanels for detached buildings

– Solar PV combiner boxes with breaker protection

– Service equipment for outdoor structures

| Characteristic | Junction Box | Distribution Box |

|---|---|---|

| Primäre Funktion | Wire connections/splices | Circuit distribution/protection |

| Contains Breakers | No | Yes |

| Typical Size | 4″×4″ to 12″×12″ | 12″×12″ to 24″×36″+ |

| NEC-Artikel | 314 | 312, 408 |

| Cost Range | $5-$50 | $50-$500+ |

| Installation Complexity | Mäßig | High – often requires electrician |

🎯 Profi-Tipp: If you’re simply connecting wires for landscape lighting or routing cables, you need a junction box. If you’re installing equipment that requires its own circuit breaker (like a pool pump), you need a distribution box or disconnect panel.

Standard Junction Box

A basic weatherproof enclosure for wire-to-wire connections with no special features beyond protection.

✅ Vorteile:

– Simple, affordable, widely available

– Easy to install with basic tools

– Sufficient for most residential outdoor wiring needs

– Available in many sizes to match project requirements

❌ Disadvantages:

– Limited space for large or complex wire connections

– Basic features only—no special provisions for large cables

– Must be carefully sized per NEC 314.16 box fill calculations

Best For: Landscape lighting connections, outdoor outlet circuits, simple conduit junctions, residential outdoor wiring projects under 20 amps

Pull Box (Larger Access Box)

A larger junction box specifically designed to facilitate pulling wires through conduit systems, with extra space for wire bending and routing.

✅ Vorteile:

– Large interior volume makes wire pulling easier

– Adequate space for bending radius requirements (NEC 314.28)

– Can accommodate multiple conduit runs entering from different directions

– Simplifies troubleshooting and future modifications

❌ Disadvantages:

– More expensive than standard boxes

– Requires more mounting space

– Larger profile may be less aesthetically pleasing

Best For: Conduit systems with multiple bends, commercial installations, installations with large conductors (6 AWG and larger), complex routing situations

💡 Key Difference: NEC 314.28 requires pull boxes to have minimum dimensions based on conductor size. For straight pulls, the box length must be at least 8 times the diameter of the largest conduit. For angle pulls, specific calculation rules apply.

Splice Box (Wire Connection Focus)

Similar to standard junction boxes but often with features specifically designed for multiple wire splices, such as built-in wire management or terminal blocks.

✅ Vorteile:

– Organized wire management features

– Sometimes includes pre-installed terminal blocks

– Designed for high wire count applications

– Clear labeling areas for circuit identification

❌ Disadvantages:

– May be more expensive than basic boxes

– Specific features might not fit all applications

– Can be oversized for simple projects

Best For: Multi-circuit outdoor installations, security/low-voltage systems, outdoor lighting with multiple zones, applications requiring numerous wire splices

PVC (Non-Metallic) Junction Boxes

Constructed from durable PVC plastic with UV stabilizers and gasket seals.

✅ Vorteile:

– Completely corrosion-proof—ideal for coastal areas

– Lightweight and easy to handle

– No grounding bonding required to the box itself

– Most affordable option for weatherproof protection

– Excellent chemical resistance

❌ Disadvantages:

– Can become brittle in extreme cold

– Lower impact resistance than metal boxes

– Cannot be used where metallic wiring methods require grounding continuity through the box

– May have lower temperature ratings

Best For: Coastal environments, areas with high humidity, chemical exposure areas, budget-conscious residential projects

Galvanized Steel Junction Boxes

Steel boxes with zinc galvanizing coating for corrosion protection.

✅ Vorteile:

– Excellent impact and physical damage resistance

– Lower cost than stainless steel or aluminum

– Provides grounding continuity for metallic conduit systems

– High temperature tolerance

– Familiar to most electricians

❌ Disadvantages:

– Can rust in harsh environments (coastal, industrial)

– Heavier than non-metallic or aluminum options

– Requires grounding bonding connections

– Galvanizing can degrade over time

Best For: Standard residential outdoor applications, inland areas with moderate climate, installations requiring metal box grounding continuity

Stainless Steel Junction Boxes

Premium boxes constructed from 304 or 316 stainless steel for maximum corrosion resistance.

✅ Vorteile:

– Superior corrosion resistance, even in coastal/marine environments

– Excellent mechanical strength and impact resistance

– Long service life with minimal maintenance

– Professional appearance

– Withstands extreme temperatures

❌ Disadvantages:

– Significantly more expensive (3-5× cost of galvanized steel)

– Heavier weight requires stronger mounting

– Overkill for standard residential applications

Best For: Coastal/marine installations, industrial environments, food processing facilities, premium residential projects, high-corrosion risk locations

Aluminum Junction Boxes

Lightweight metal boxes offering good corrosion resistance at moderate cost.

✅ Vorteile:

– Excellent corrosion resistance without the cost of stainless steel

– Lightweight compared to steel options

– Good conductivity for grounding purposes

– Does not rust

❌ Disadvantages:

– Can corrode in certain chemical environments

– Lower impact resistance than steel

– More expensive than galvanized steel

– Special considerations needed when used with dissimilar metals (galvanic corrosion)

Best For: Moderate corrosion risk environments, weight-sensitive installations, commercial/industrial applications where corrosion is a concern

NEMA 3R (Raintight)

Provides protection against rain, sleet, and external ice formation. Most common outdoor rating for residential use.

Protection Level: Protects against falling rain and external ice, but NOT submersion, direct hose spray, or windblown dust.

Common Applications: Residential outdoor outlets, landscape lighting junctions, general outdoor wiring not subject to hose spray or flooding.

NEMA 4/4X (Watertight)

Provides protection against hose-directed water, splashing, and limited submersion. NEMA 4X adds corrosion resistance.

Protection Level: Watertight seal prevents water entry even during direct spray. NEMA 4X specifically resists corrosion.

Common Applications: Pool/spa equipment areas, car wash facilities, food processing areas, industrial washdown areas, coastal installations.

NEMA 6/6P (Submersible)

Designed for occasional or prolonged submersion at specified depths.

Protection Level: Complete water ingress protection during temporary submersion. Different ratings specify depth and duration.

Common Applications: Below-grade installations subject to flooding, pond/fountain equipment, marine applications, areas subject to temporary submersion.

NEC Article 314 provides comprehensive requirements for junction boxes, both indoor and outdoor. Understanding these rules ensures code-compliant, safe installations.

Requirement: Boxes in damp or wet locations must prevent moisture from entering or accumulating in the box.

What This Means: Any outdoor junction box must be listed for wet locations (NEMA 3R minimum). The box must be:

– Installed so that water cannot accumulate inside

– Mounted with the opening downward or with weatherproof cover when opening is not downward

– Sealed with appropriate gaskets

Practical Application: When mounting an outdoor electrical junction box on a vertical wall, ensure the conduit entries are on the bottom or sides—never on top where water could pool. If top entries are unavoidable, use a weatherproof hub with draining capability.

Requirement: Boxes must have sufficient volume for all conductors, devices, and fittings contained within.

Volume Allowances per Conductor Size:

| Conductor Size (AWG) | Volume per Conductor | Common Application |

|---|---|---|

| 18 AWG | 1.5 cubic inches | Low-voltage, thermostats |

| 16 AWG | 1.75 cubic inches | Low-voltage, doorbells |

| 14 AWG | 2.0 cubic inches | 15A lighting circuits |

| 12 AWG | 2.25 cubic inches | 20A receptacle circuits |

| 10 AWG | 2.5 cubic inches | 30A appliance circuits |

| 8 AWG | 3.0 cubic inches | 40A equipment |

| 6 AWG | 5,0 Kubikzoll | 50-60A equipment |

Additional Count Rules:

– Each device (receptacle or switch): Counts as 2 conductors of largest size connected

– Cable clamps: All clamps together count as 1 conductor of largest size

– Equipment ground wires: All grounds count as 1 conductor of largest size

– Fixture studs/hickeys: Each counts as 1 conductor of largest size

Berechnungsbeispiel:

Outdoor junction box containing:

– 3 incoming 12 AWG conductors (hot, neutral, ground)

– 3 outgoing 12 AWG conductors (hot, neutral, ground)

– 1 cable clamp

Total count:

– 6 conductors (2 hots + 2 neutrals + 1 ground counted as 1 + 1 clamp counted as 1) = 5 conductors for volume purposes

– Required volume: 5 × 2.25 = 11.25 cubic inches minimum

A standard 4″×4″×2-1/8″ box provides 30.3 cubic inches—adequate for this installation.

Straight Pull Requirement: Minimum box length = 8 times the trade diameter of the largest conduit

Beispiel: If you have 1-inch conduit with 6 AWG conductors, the box must be at least 8 inches long in the direction of the pull.

Angle Pull Requirement: More complex calculations apply. The distance from the conduit entry to the opposite wall must be at least 6 times the trade diameter of the largest conduit, plus the sum of all other conduit diameters entering that wall.

Practical Impact: For larger conductors common in solar, pool, or subpanel applications, you cannot use small junction boxes. NEC mandates pull box sizing to ensure adequate bending radius and prevent wire damage during installation.

Requirement: Junction boxes must be so installed that the wiring is accessible without removing any part of the building or structure.

What This Means:

– No burying junction boxes behind drywall, siding, or permanent finishes

– No burying junction boxes underground or in concrete

– Must be able to remove the box cover without tools if the box is concealed in a finished area (outdoor usually requires tools)

– Must have adequate working space per NEC 110.26 for maintenance

Practical Application: When planning outdoor wiring, you cannot simply bury direct-burial cable splices. Any connection point must be in an accessible junction box—typically mounted on a building exterior, post, or accessible structure.

⚠️ Code Violation Warning: Burying wire splices underground, even in an outdoor electrical junction box, violates NEC 314.29. Buried boxes are not accessible without excavation. Use only continuous runs of direct-burial cable between accessible junction points.

Requirement: Boxes must be rigidly supported and cannot rely on conduit or cables for support (except specific exceptions).

Mounting Methods:

– Surface mounting: Secure to building wall, post, or structure with appropriate anchors

– Bracket mounting: Use approved box brackets rated for the box weight and conduit loads

– Conduit mounting: Only for rigid metal conduit (RMC) or intermediate metal conduit (IMC) with specific conditions

Practical Application: When installing outdoor junction boxes on brick, concrete, or masonry, use appropriate masonry anchors—not just screws into mortar joints. The box must remain secure even if a moderate force is applied (someone leaning a ladder against it, for example).

Outdoor electrical junction boxes are essential for landscape lighting installations where multiple light fixtures connect to a single circuit.

Requirements:

– NEMA 3R rating minimum for above-grade installations

– Proper box fill calculation for all wire connections (typically 12 AWG or 14 AWG)

– Low-voltage transformer connections may require larger boxes

– Ground fault circuit interrupter (GFCI) protection required per NEC 210.8

Typical Configuration:

Main circuit from house → GFCI outdoor outlet → outdoor junction box → multiple branch circuits to light fixtures. The junction box houses the split where one incoming circuit feeds multiple outgoing paths to lighting zones.

🎯 Profi-Tipp: When wiring landscape lighting, install the outdoor electrical junction box near the transformer or first fixture in the zone. This minimizes exposed wire runs and makes troubleshooting easier. Label each outgoing circuit inside the box (e.g., “Front Path,” “Garden Lights,” “Accent Spots”).

Pool and spa equipment areas have unique requirements due to water proximity and the hazards associated with swimming pools.

Requirements:

– NEMA 4/4X rating strongly recommended due to splashing and hose spray

– Must be located per NEC 680 requirements (specific distances from pool edge)

– Bonding connections required for metal junction boxes

– All circuits require GFCI protection per NEC 680.22(B)

– Corrosion-resistant materials essential (stainless steel or non-metallic)

Typical Configuration:

Service panel → Pool subpanel or disconnect → outdoor junction box → pump, heater, lights, and other pool equipment. The junction box often serves as a transition point where circuit conductors split to feed multiple pieces of equipment.

Special Considerations: Pool areas have stringent bonding requirements. Metal junction boxes must be bonded to the pool bonding grid. This is separate from the equipment grounding conductor and serves to equalize potential between metal objects around the pool.

Solar photovoltaic systems typically use outdoor electrical junction boxes at conduit transition points between the roof array and ground-level equipment.

Requirements:

– UV-resistant materials (PVC degrades faster under direct sun—consider gray electrical PVC or metal)

– Sized per NEC 314.28 when containing large conductors (common in solar: 10 AWG to 2 AWG)

– Listed for DC applications if containing DC conductors (most standard boxes are acceptable, but verify listing)

– NEMA 3R minimum; NEMA 4X preferred for rooftop installations subject to direct weather

Typical Configuration:

Rooftop array → conduit down roof/wall → outdoor junction box at building entry point → conduit to inverter location. The junction box provides an accessible point where you can verify wire integrity without accessing the roof.

When adding outdoor outlets for power tools, holiday decorations, or appliances, junction boxes route circuits to multiple receptacle locations.

Requirements:

– NEMA 3R minimum for above-grade boxes

– Weatherproof-in-use covers required for receptacles per NEC 406.9(B)(1)

– GFCI protection required for all outdoor outlets per NEC 210.8(A)(3)

– Proper box fill calculations for switch/receptacle devices

Typical Configuration:

Interior panel → exterior wall penetration → outdoor junction box → multiple outdoor outlet locations. The junction box splits the circuit to serve several outdoor receptacles without home-run wiring from each one back to the panel.

Feeding electricity to detached garages, sheds, or workshops requires outdoor wiring runs, often with junction points.

Requirements:

– Junction boxes at building entry/exit points

– Proper grounding per NEC 250.32 (detached structures)

– Protection from physical damage per NEC 300.5

– May require pull boxes if using large conductors and multiple conduit bends

Typical Configuration:

Main house panel → underground conduit or overhead service → outdoor junction box at house exterior → conduit run to detached building → junction box at building entry → building subpanel. Junction boxes provide transition points and maintain accessibility for future troubleshooting.

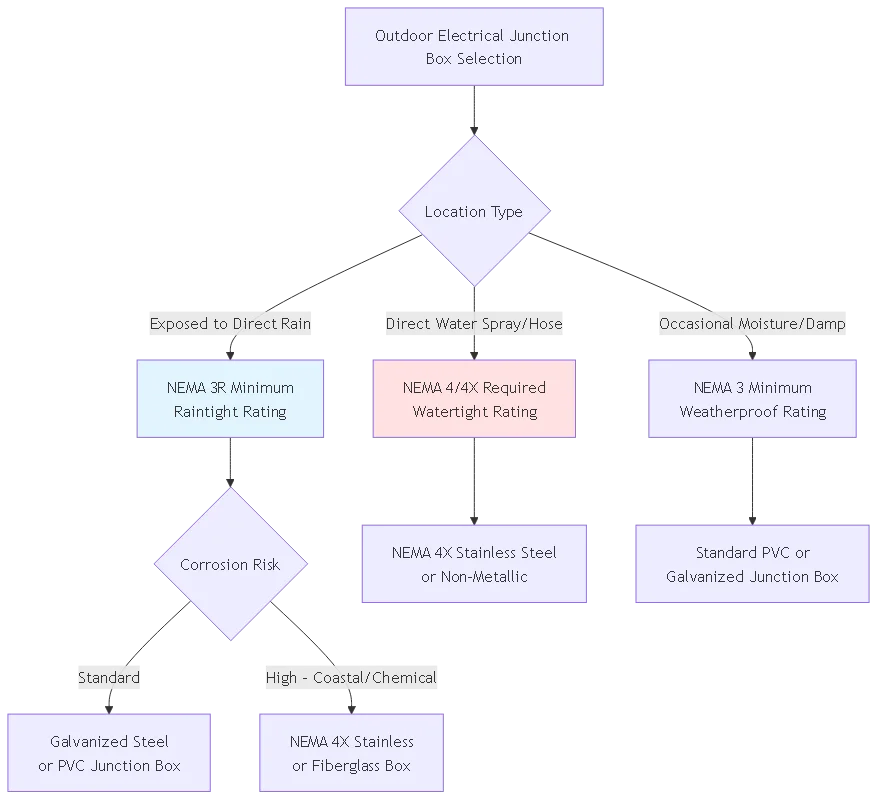

Assessment Questions:

– Will the box be exposed to direct rain or only occasional moisture?

– Is there risk of water spray from hoses, sprinklers, or cleaning?

– Is the location subject to potential flooding or submersion?

– Are there corrosive conditions (coastal salt air, chemicals, industrial environment)?

Auswahlhilfe:

| Environment Conditions | Mindest-NEMA-Bewertung | Empfohlenes Material |

|---|---|---|

| Covered porch, under eaves, limited rain exposure | NEMA 3 | PVC or galvanized steel |

| Exposed exterior wall, direct rain | NEMA 3R | PVC or galvanized steel |

| Pool area, car wash, hose spray areas | NEMA 4 | PVC or stainless steel |

| Coastal areas, high corrosion risk | NEMA 4X | Stainless steel or PVC |

| Below-grade, subject to occasional flooding | NEMA 6/6P | PVC or fiberglass |

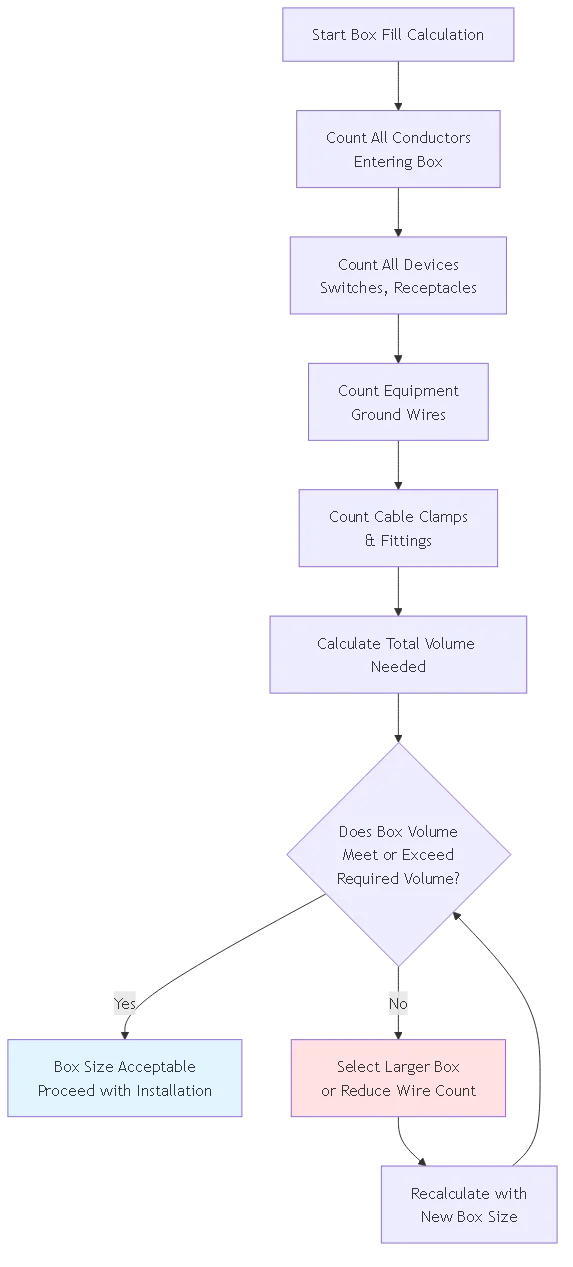

Formel: Required Volume = (Number of conductors × volume per conductor size) + device allowances + clamp allowances

Beispiel:

You’re connecting landscape lighting with:

– 1 incoming 14/2 w/ground cable (2 conductors + 1 ground)

– 3 outgoing 14/2 w/ground cables (6 conductors + 3 grounds)

– Total: 8 conductors + 4 grounds (counted as 1) + cable clamps (counted as 1) = 10 conductor equivalents

– Required volume: 10 × 2.0 cubic inches = 20 cubic inches

Box Selection: Standard 4″×4″×1-1/2″ box = 21.0 cubic inches (adequate). A 4″×4″×2-1/8″ box = 30.3 cubic inches (better for easier wire management).

💡 Practical Tip: While NEC gives minimums, choosing a box with 20-30% more volume than calculated makes wire connections easier and leaves room for future additions.

Decision Matrix:

Choose PVC when:

– Budget is primary concern

– Corrosion is a significant risk (coastal, chemical environments)

– Weight is a consideration

– You’re using non-metallic wiring methods (NM cable, PVC conduit)

Choose Galvanized Steel when:

– Impact resistance is important (high-traffic areas)

– You’re using metallic conduit systems

– Grounding continuity through the box is required

– Standard inland climate with moderate conditions

Choose Stainless Steel when:

– Budget allows for premium protection

– Coastal/marine environment with salt exposure

– Industrial environment with corrosive chemicals

– Long service life with minimal maintenance is priority

– Professional appearance is important

Choose Aluminum when:

– Moderate corrosion resistance needed at mid-range cost

– Weight is a significant concern

– Non-coastal moderate environment

Count how many conduit runs will enter the box and from which directions (top, bottom, sides).

Considerations:

– Standard boxes have knockouts on all sides, but verify before purchasing

– Some specialty boxes have pre-formed conduit hubs (saves installation time)

– Ensure knockout sizes match your conduit sizes (1/2″, 3/4″, 1″, etc.)

– Plan for proper orientation (avoid top entries where water can pool)

Beispiel: If you need three 1/2″ conduit entries from the bottom and one 3/4″ entry from the side, ensure the box has sufficient knockouts in those locations.

Built-in Mounting Brackets: Some outdoor electrical junction boxes include integral mounting ears or brackets, simplifying installation on various surfaces.

Terminal Blocks: For applications with many wire splices, boxes with factory-installed terminal blocks can save time and ensure neat connections.

Transparent Covers: Specialized boxes with clear covers allow visual inspection of connections without opening the box—useful for monitoring low-voltage systems or troubleshooting.

Larger Cover Screws: In environments requiring frequent access, boxes with captive cover screws (that don’t fall out when loosened) save time and frustration.

Problem: Indoor junction boxes lack weatherproof gaskets, sealed knockouts, and corrosion-resistant materials. Moisture will enter the box, corroding connections and creating shock and fire hazards.

Common scenarios:

– Using leftover indoor plastic boxes for “temporary” outdoor lighting

– Installing standard metal handy boxes on exterior walls

– Assuming paint or caulk will make an indoor box weatherproof

Berichtigung: Always use boxes specifically listed for wet locations with appropriate NEMA ratings. Indoor boxes will fail inspection and create genuine safety hazards. The cost difference is minimal—there’s no reason to compromise.

⚠️ Warning: Even “weatherproof” boxes designed for damp locations (NEMA 1) may not be adequate for direct rain exposure. Verify the box is rated for wet locations if it will experience rain, snow, or sprinkler exposure.

Problem: Cramming too many wires into a junction box violates NEC 314.16, creates heat buildup, makes proper connections difficult, and can damage wire insulation.

Common scenarios:

– Using the smallest available box to save money or space

– Adding additional circuits to existing boxes without recalculating fill

– Ignoring clamps, devices, and ground wires in calculations

– Forcing connections closed when wires resist

Berichtigung: Perform proper box fill calculations before purchase. When in doubt, choose the next larger box size. If you cannot close the box cover without forcing wires, the box is too small. Recalculate and upgrade to an appropriately sized box.

Problem: NEC 314.29 requires all junction boxes remain accessible without removing permanent building components. Burying boxes underground or behind permanent siding violates code and makes future maintenance impossible.

Common scenarios:

– Burying junction boxes during landscaping to hide them

– Concealing boxes behind vinyl siding, stucco, or other finishes

– Installing boxes in areas that will be covered by decks or permanent structures

– Assuming “I’ll remember where it is” is adequate

Berichtigung: Plan outdoor wiring to eliminate the need for buried junction boxes. Use continuous runs of direct-burial cable between accessible points. Surface-mount junction boxes on building exteriors, posts, or permanent structures where they remain accessible. If aesthetic concerns exist, use decorative covers or landscaping that doesn’t fully conceal the box.

Problem: Junction boxes must be rigidly secured per NEC 314.23. Boxes that rely solely on conduit for support, or that are inadequately anchored, can sag, pull conduit loose, or fall off entirely.

Common scenarios:

– Mounting boxes with too few or undersized screws

– Using screws only in mortar joints instead of brick or concrete

– Relying on PVC conduit to support a heavy box

– Using anchors not rated for the substrate (wrong anchor type for concrete, brick, etc.)

Berichtigung: Use appropriate mounting hardware for the substrate. For masonry, use proper concrete anchors, not just screws in mortar. For wood, use appropriate lag screws or wood screws. Ensure the box is secured independently of conduit unless specifically using rigid metal conduit and meeting all code requirements for conduit support.

Problem: Using a NEMA 3R box in an environment requiring NEMA 4 (hose spray areas) or using non-corrosion-resistant materials in coastal areas leads to premature failure.

Common scenarios:

– Using standard galvanized boxes near swimming pools or coastal areas

– Installing NEMA 3R boxes in car wash or food service areas with hose spray

– Assuming “waterproof” means suitable for submersion

– Not accounting for future environmental changes

Berichtigung: Evaluate the actual environment and select the appropriate NEMA rating. When uncertain, choose the higher protection level. In coastal areas, always use NEMA 4X corrosion-resistant materials (stainless steel or non-metallic). For pool and spa areas, NEMA 4/4X is essential.

Problem: Metal junction boxes must be properly bonded to the equipment grounding system. Missing or inadequate grounding creates shock hazards if a fault occurs.

Common scenarios:

– Not connecting ground wires to metal boxes

– Using improper grounding screws or methods

– Assuming the conduit provides adequate grounding without bonding jumpers

– Not bonding boxes in pool areas to the pool bonding grid

Berichtigung: All metal outdoor electrical junction boxes must have an equipment grounding conductor properly terminated to the box grounding terminal. Use green grounding screws or listed grounding clips. In pool areas, provide separate bonding connections per NEC 680 requirements.

A junction box is a weatherproof enclosure that houses wire-to-wire connections (splices) where electrical paths meet or split, without any circuit protection devices. A distribution box (or panel) contains circuit breakers or fuses and serves as a point where one incoming circuit divides into multiple protected outgoing circuits. Junction boxes are governed by NEC Article 314 and typically range from 4″×4″ to 12″×12″, containing only wire connections and no breakers. Distribution boxes fall under NEC Articles 312 and 408, are larger (often 12″×12″ to 24″×36″ or more), and include bus bars and overcurrent protection devices.

The key distinction is function: junction boxes simply connect wires together, while distribution boxes distribute power to multiple branch circuits with individual breaker protection for each circuit. For example, connecting landscape lighting zones requires only a junction box, but installing a pool pump that needs its own dedicated circuit breaker requires a distribution panel or disconnect box. Cost and complexity also differ significantly—junction boxes cost $5-50 and involve moderate installation complexity, while distribution boxes cost $50-500+ and often require professional electrician installation due to the complexity of bus work and breaker installation.

NEC 314.16 requires boxes to have sufficient volume for all conductors, devices, clamps, and fittings. Each conductor requires a specific volume based on wire size: 14 AWG requires 2.0 cubic inches, 12 AWG requires 2.25 cubic inches, and 10 AWG requires 2.5 cubic inches per conductor. Count all current-carrying conductors (hot and neutral wires) entering the box. Equipment grounding conductors count as only one conductor of the largest size, regardless of how many enter. Each device (receptacle or switch) counts as two conductors of the largest wire size connected to it. All cable clamps together count as one conductor of the largest size entering the box.

To calculate, multiply the total conductor count by the volume requirement for that wire size, then ensure your selected box has equal or greater volume. For example, if you have 6 total conductors of 12 AWG wire (including device and clamp allowances), you need 6 × 2.25 = 13.5 cubic inches minimum. A standard 4″×4″×1-1/2″ box provides 21.0 cubic inches, which would be adequate with room to spare. Always choose a box with 20-30% more volume than the calculated minimum to make wire connections easier and accommodate potential future additions. Box volumes are stamped inside the box or listed in manufacturer specifications.

No, you cannot bury an outdoor electrical junction box underground. NEC 314.29 explicitly requires that junction boxes be installed so the wiring is accessible without removing any part of the building or permanent structure. A buried box requires excavation to access, which violates this requirement. This rule exists because electrical connections are the most likely failure points in a wiring system, and they must remain accessible for inspection, maintenance, and troubleshooting throughout the life of the installation.

Instead of burying junction boxes, use continuous runs of direct-burial rated UF cable between accessible junction points. Direct-burial cable can be buried per NEC 300.5 requirements (typically 24 inches deep for residential branch circuits, 18 inches if protected by GFCI), but any splices or connections must occur in accessible above-ground junction boxes. Mount junction boxes on building exteriors, posts, or other permanent structures where they remain visible and accessible. If aesthetics are a concern, consider using decorative covers, strategic landscaping that doesn’t fully conceal the box, or color-matched boxes that blend with the building exterior. The safety and code compliance benefits of accessible junction boxes far outweigh aesthetic considerations.

For pool and spa areas, you need NEMA 4 or NEMA 4X rated outdoor electrical junction boxes. NEMA 4 provides watertight protection against hose-directed water and splashing, which is common in pool environments. NEMA 4X adds corrosion resistance, which is essential in pool areas where chlorine, salt (for saltwater pools), and other chemicals create highly corrosive conditions. Standard NEMA 3R (raintight) boxes are not adequate for pool applications because they don’t protect against direct water spray or the corrosive chemicals present.

Material selection is also critical: stainless steel or non-metallic (PVC/fiberglass) boxes are strongly recommended for pool areas. Standard galvanized steel will corrode rapidly in pool environments. NEC Article 680 provides specific requirements for pool, spa, and fountain installations, including grounding and bonding requirements. Metal junction boxes in pool areas must be bonded to the equipotential bonding grid per NEC 680.26, which is separate from the equipment grounding conductor and serves to equalize electrical potential between all metal objects in the pool area.

Additionally, all circuits in pool areas require GFCI protection per NEC 680.22, and specific distance requirements apply to where junction boxes can be located relative to the pool edge. Consult NEC Article 680 or hire a licensed electrician familiar with pool wiring requirements, as pool installations have unique hazards and stringent code requirements beyond standard outdoor wiring.

The junction box itself doesn’t require GFCI protection, but the circuits connected through it likely do. NEC 210.8(A)(3) requires GFCI protection for all outdoor outlets, which means any circuit feeding outdoor receptacles must be GFCI-protected. This protection can be provided by GFCI circuit breakers at the panel or GFCI receptacles at the first outlet in the circuit. NEC 210.8(B)(4) extends GFCI requirements to outdoor outlets for commercial installations as well.

However, if the outdoor electrical junction box contains only wire splices for circuits that don’t feed receptacles—such as dedicated circuits for hardwired outdoor lighting, pool equipment, or HVAC condensers—GFCI protection may not be required by code (though it may still be advisable for additional protection). The key is understanding what the circuit feeds: if it feeds any outdoor receptacles where someone could plug in equipment, GFCI protection is mandatory. If it’s a dedicated circuit for permanently installed equipment, check NEC requirements specific to that equipment type.

Special cases include pool and spa circuits (NEC 680.22 requires GFCI for all 15A and 20A pool circuits), outdoor lighting circuits in wet locations, and fountain circuits (all require GFCI). When in doubt, adding GFCI protection provides an additional layer of safety even when not strictly required by code. GFCI protection detects ground faults and trips the circuit within milliseconds, preventing potentially fatal electric shock—particularly important in outdoor environments where moisture increases shock risk.

You need a pull box instead of a standard junction box when using conductors 4 AWG or larger, or when NEC 314.28 minimum dimension requirements exceed the size of standard junction boxes. NEC 314.28 provides specific sizing rules for pull boxes: for straight pulls (where conductors enter one side and exit the opposite side), the box length must be at least 8 times the trade diameter of the largest conduit. For angle pulls (where conductors enter one side and exit an adjacent side), the distance from the conduit entry to the opposite wall must be at least 6 times the trade diameter of the largest conduit, plus the sum of all other conduit diameters entering that wall.

For example, if you’re pulling 4 AWG conductors through 1-inch conduit with a straight pull, the box must be at least 8 inches long (8 × 1″ = 8″). If you have an angle pull with one 1-inch conduit and two 3/4-inch conduits, the calculation becomes (6 × 1″) + (3/4″) + (3/4″) = 7.5 inches minimum. These larger dimensions ensure adequate wire bending radius per NEC 300.34, preventing damage to conductor insulation during installation.

Pull boxes are also beneficial (though not always required) in complex conduit systems with multiple bends, where the extra space makes pulling wires easier and reduces the risk of insulation damage. Common applications requiring pull boxes include solar PV systems with large conductors (often 10 AWG to 2 AWG), subpanel feeds to detached buildings, pool equipment with dedicated 6 AWG or larger circuits, and commercial installations with complex conduit routing. When conductor size or conduit configuration requires dimensions beyond what standard junction boxes provide, specify a pull box and perform the NEC 314.28 calculations to ensure code compliance.

Outdoor electrical junction boxes require periodic inspection and minimal maintenance to ensure continued weatherproof protection and safe operation. Annually (or after severe weather events), inspect the box exterior for cracks, corrosion, or damage to the enclosure material. Check that the cover gasket remains intact and pliable—hardened, cracked, or missing gaskets compromise weatherproof protection and should be replaced. Verify cover screws are tight and the cover sits flush against the gasket; loose covers allow moisture entry.

Every 2-3 years (or if you notice any electrical issues), open the box and inspect internal connections. Look for signs of moisture entry (corrosion, water stains, or mineral deposits), which indicate the weatherproofing has failed. Check wire connections for tightness—outdoor temperature cycling can cause connections to loosen over time. Verify wire insulation shows no cracking, melting, or damage. For metal boxes, check bonding and grounding connections to ensure they remain secure.

If you find moisture inside the box, determine the entry point (failed gasket, damaged knockout seal, or conduit infiltration) and correct it. Replace damaged gaskets, seal conduit entries properly, or upgrade to a higher NEMA rating if the environment is more severe than the box rating. Clean any corrosion from connections, verify tightness, and consider applying dielectric grease to connections in corrosive environments to prevent future issues.

For boxes in harsh environments (coastal areas, pool areas, or industrial locations), more frequent inspection is warranted—every 6 months or quarterly. Stainless steel and non-metallic boxes require less maintenance than galvanized steel, which may need replacement if significant corrosion develops. Always turn off power at the circuit breaker before opening any junction box for inspection. If you’re uncomfortable with electrical work, hire a licensed electrician for periodic inspection and maintenance.

Understanding outdoor electrical junction boxes is essential for any homeowner planning exterior electrical projects, from simple landscape lighting to complex pool installations. These weatherproof enclosures protect critical wire connections from moisture, physical damage, and environmental exposure while meeting stringent NEC code requirements.

Wichtigste Erkenntnisse:

1. Outdoor electrical junction boxes are legally required by NEC 314 for all wire connections outside protective cable sheaths, with specific requirements for weather protection, accessibility, and proper sizing.

2. Junction boxes differ from distribution boxes: Junction boxes house only wire connections, while distribution boxes contain circuit breakers and power distribution equipment—choose based on your application needs.

3. NEMA ratings matter: Select NEMA 3R minimum for rain exposure, NEMA 4/4X for hose spray or corrosive environments, and NEMA 6 for submersible applications. Match the rating to your specific environment.

4. Proper sizing prevents code violations: Use NEC 314.16 box fill calculations to ensure adequate volume for all conductors, devices, and fittings. When using large conductors (4 AWG+), follow NEC 314.28 pull box sizing rules.

5. Accessibility is mandatory: Never bury junction boxes underground or conceal them behind permanent structures. All junction boxes must remain accessible for inspection and maintenance without excavation or removing building components.

Investing time in proper outdoor electrical junction box selection and installation ensures code compliance, long-term reliability, and most importantly, safety for your family and property.

Related Resources:

– Waterproof Distribution Box Guide: Complete Selection & Installation

– DC Circuit Breaker Fundamentals: Types, Applications & Selection

– DC Fuse Complete Guide: Sizing, Selection & Protection

Ready to ensure your outdoor electrical installation meets code? Our technical team at SYNODE specializes in weatherproof electrical enclosures and protection systems. Whether you’re installing landscape lighting, pool equipment, or solar PV systems, we can help you select the right outdoor electrical junction boxes and components for code-compliant, reliable installations. Contact our engineering department for project-specific recommendations and technical support.

Zuletzt aktualisiert: Oktober 2025

Autor: SYNODE Technisches Team

Rezensiert von: Fachbereich Elektrotechnik