Dirección

304 North Cardinal

Dorchester Center, MA 02124

Horas de trabajo

De lunes a viernes: de 7.00 a 19.00 horas

Fin de semana: 10.00 A 17.00 HORAS

Dirección

304 North Cardinal

Dorchester Center, MA 02124

Horas de trabajo

De lunes a viernes: de 7.00 a 19.00 horas

Fin de semana: 10.00 A 17.00 HORAS

Outdoor electrical boxes are critical components in solar photovoltaic installations, providing weatherproof protection for electrical connections, protection devices, and distribution equipment. Selecting the right enclosure ensures system reliability, safety compliance, and long-term performance in harsh environmental conditions.

Professional solar installers face unique challenges when specifying outdoor electrical boxes. Unlike indoor applications, exterior enclosures must withstand UV radiation, temperature extremes, moisture ingress, and physical impacts while maintaining code compliance and protecting sensitive electrical equipment. This comprehensive guide covers everything from IP rating selection to installation best practices, helping you specify the optimal outdoor electrical box for residential, commercial, and utility-scale solar projects.

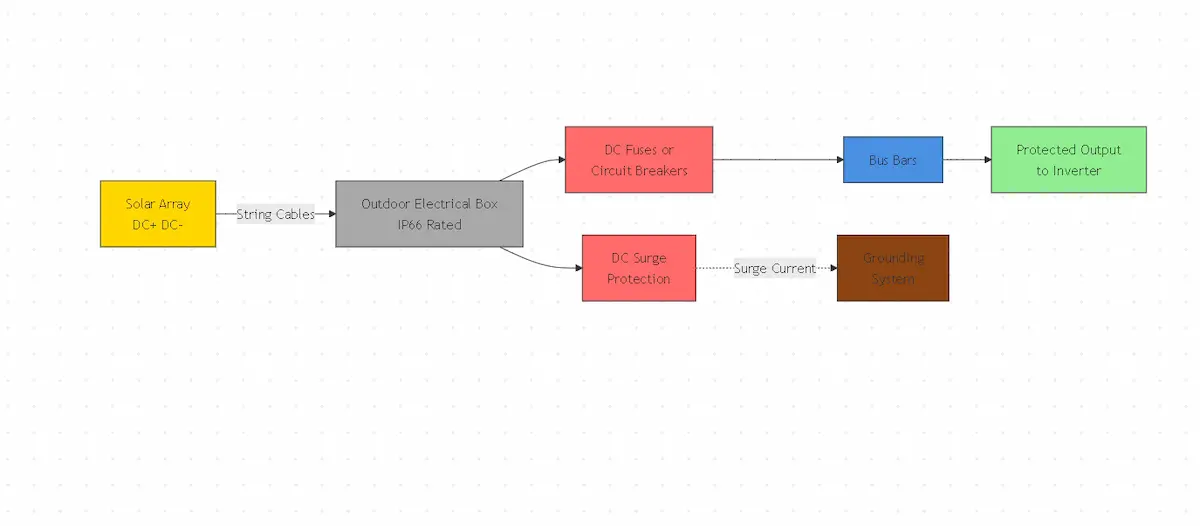

An outdoor electrical box is a weatherproof enclosure designed to house electrical connections, components, and protection devices in exterior environments. In solar PV applications, these boxes protect Disyuntores de CC, Fusibles CC, surge protection devices, and wiring connections from environmental hazards.

Environmental protection forms the primary purpose of outdoor electrical boxes. These enclosures create a sealed barrier against rain, snow, humidity, dust, and airborne contaminants that could cause short circuits, corrosion, or equipment failure. Quality outdoor boxes maintain their protective seal through decades of temperature cycling and UV exposure.

Equipment organization within outdoor electrical boxes improves system maintainability and troubleshooting efficiency. Proper enclosures provide adequate space for Interruptores-seccionadores de CC, circuit protection devices, and wire management while maintaining required clearances per NEC Article 110.26.

Safety compliance depends on properly rated outdoor electrical boxes. NEC Article 314 and local electrical codes specify minimum requirements for box sizing, mounting, grounding, and labeling. Using listed enclosures from manufacturers meeting UL and NEMA standards ensures inspection approval and liability protection.

Solar installers deploy outdoor electrical boxes throughout photovoltaic installations. At the array level, boxes house string combiners with breakers or fuses protecting individual strings. For combiner box applications, larger enclosures consolidate multiple strings before routing DC power to inverters. AC disconnect locations require outdoor boxes protecting the interface between inverter output and utility connection. Monitoring equipment often requires separate weatherproof enclosures for data acquisition and communication devices.

Información clave: For most professional solar installations, IP66-rated outdoor electrical boxes provide the optimal balance of weather protection, durability, and cost-effectiveness for 25+ year system lifespans.

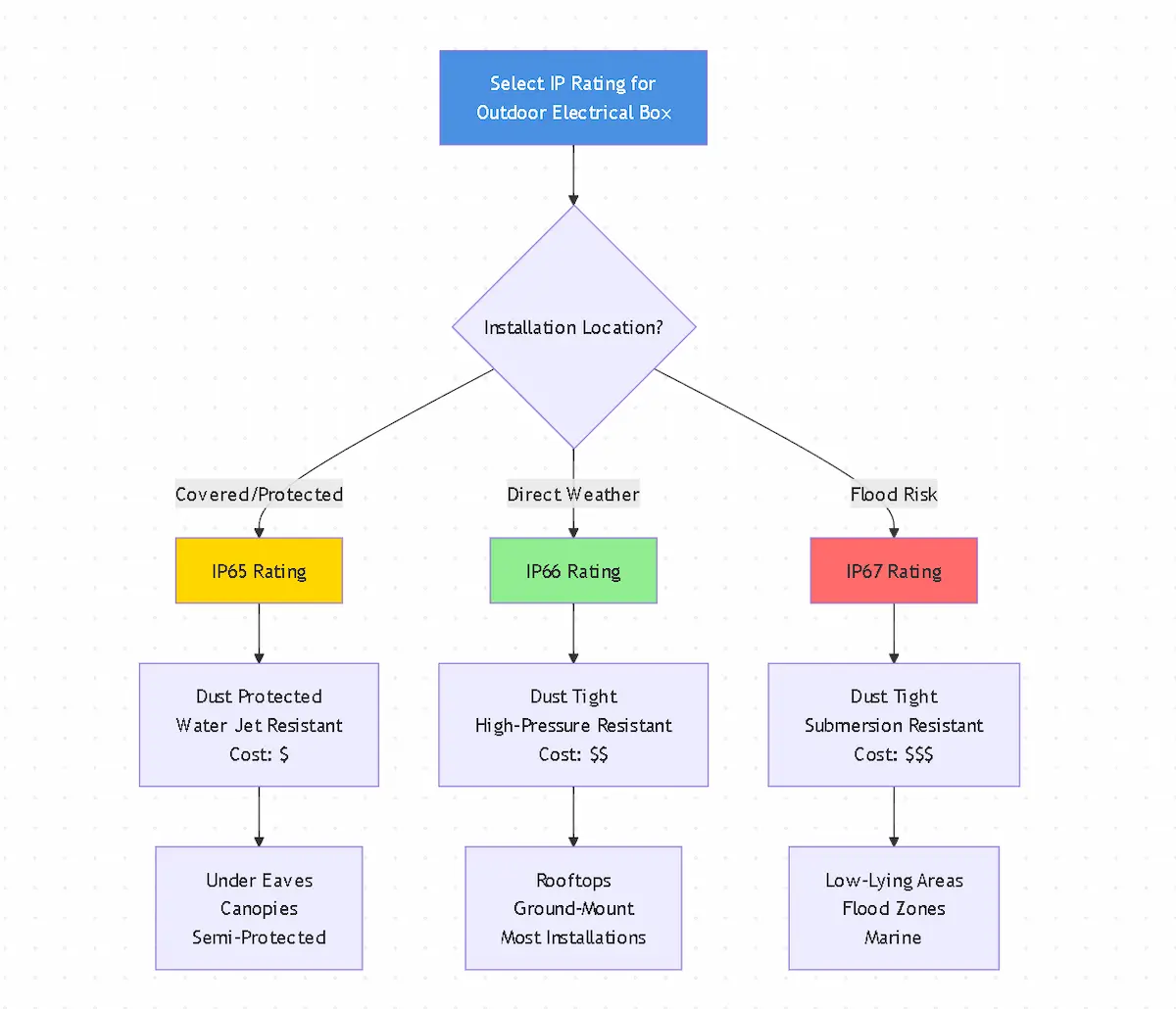

The Ingress Protection (IP) rating system, defined by IEC 60529, standardizes how enclosures protect against solid objects and liquids. Understanding IP ratings is essential for specifying appropriate outdoor electrical boxes for solar installations.

The IP rating consists of two digits following “IP”: the first digit indicates solid particle protection (0-6), while the second digit specifies liquid ingress protection (0-9). For solar applications, the most relevant ratings are IP65, IP66, and IP67.

First digit (solid object protection):

Second digit (liquid ingress protection):

IP65 enclosures provide dust protection and water jet resistance suitable for covered installations or semi-protected environments.

Suitable applications:

Limitations:

⚠️ Importante: IP65-rated boxes should not be used in locations with direct weather exposure, high-pressure washing access, or areas subject to wind-driven rain. Upgrading to IP66 prevents long-term moisture and dust accumulation issues.

IP66 enclosures deliver dust-tight and high-pressure water jet protection, making them the industry standard for most outdoor solar installations.

Suitable applications:

Performance characteristics:

IP67 enclosures provide dust-tight protection plus temporary submersion resistance for applications with flooding or standing water risk.

Suitable applications:

Considerations:

| Installation Type | Recommended IP | Justification | Typical Cost |

|---|---|---|---|

| Rooftop Commercial | IP66 | Direct weather, maintenance access | $$ |

| Ground-Mount Array | IP66 | Dust exposure, rain, potential flooding | $$ |

| Covered Carport | IP65 | Protected from direct rain | $ |

| Coastal Installation | IP66 | Salt spray, high winds, corrosion risk | $$ |

| Desert Environment | IP66 | Extreme dust, sandstorms | $$ |

| Flood-Prone Area | IP67 | Temporary submersion protection | $$$ |

Consejo profesional: When in doubt between IP65 and IP66, choose IP66. The marginal cost increase (typically 10-20%) provides significantly better long-term protection and eliminates potential warranty claims from moisture ingress.

Enclosure material directly impacts durability, thermal performance, cost, and suitability for specific solar applications.

Polycarbonate outdoor electrical boxes offer excellent UV resistance and impact strength for solar installations.

Material properties:

Best suited for:

Limitations:

Fiberglass outdoor electrical boxes deliver superior strength-to-weight ratio and corrosion resistance for demanding applications.

Material properties:

Best suited for:

Limitations:

Metal outdoor electrical boxes provide maximum strength, security, and heat dissipation for professional solar installations.

Material properties:

Metal options:

Best suited for:

Considerations:

Choose polycarbonate when:

Choose fiberglass when:

Choose metal when:

Proper sizing ensures adequate space for equipment, wire management, heat dissipation, and future expansion while meeting NEC requirements.

NEC Article 314 establishes minimum box sizing based on conductor count, device size, and equipment clearances.

Minimum clearances:

Conductor fill calculations: Follow NEC 314.16 for maximum conductors based on box volume. Each conductor, device, and clamp counts toward fill limits.

For DC combiner boxes:

Typical residential combiner sizes:

For surge protection installations: DC SPD devices require:

For disconnect switches: Main DC disconnect outdoor electrical boxes need:

Calculate internal temperature rise based on:

Derating factors: Equipment generates heat during operation. For circuit breakers dissipating >50W in enclosed spaces, use metal enclosures or oversized plastic boxes with ventilation.

Adequate space prevents:

Consejo profesional: Size outdoor electrical boxes 30-40% larger than minimum NEC calculations. The modest cost increase dramatically improves installation efficiency, reduces labor time, and accommodates future system modifications without box replacement.

Optimal placement considerations:

Avoid these locations:

Surface mounting (most common for solar): Use stainless steel mounting brackets rated for enclosure weight plus 100% safety factor. Ensure backing surface supports minimum 200 lbs pull-out strength for large enclosures. Verify wall material can handle fastener loads.

Post/pole mounting (for ground-mount arrays): Use galvanized steel or aluminum posts with concrete footings. Mount outdoor electrical box height above local flood elevation plus 12 inches. Size posts to resist wind loads per local building codes.

Embedded mounting (flush-mount in walls): Ensure proper sealing and conduit entry provisions during concrete pour. This method provides cleanest appearance but limits future access and modifications.

Entry location: Bottom entries preferred to prevent water intrusion if gasket fails. Use only enclosure-rated entry hubs or grommets maintaining IP rating. Install upward-sloping conduit runs preventing water accumulation at box.

Weatherproof connections:

Per NEC Article 250, all metal outdoor electrical boxes and equipment must be properly grounded:

When installing DC circuit protection in outdoor boxes, proper grounding prevents shock hazards and ensures fault clearing.

NEC 690 mandates specific labeling for solar outdoor electrical boxes:

Symptoms: Water droplets inside box, corroded terminals, nuisance tripping

Root causes:

Solutions:

Symptoms: Nuisance breaker trips, shortened equipment life, thermal shutdowns

Root causes:

Solutions:

Symptoms: Water ingress, degraded IP rating, corroded connections

Root causes:

Solutions:

⚠️ Importante: Failed seals in outdoor electrical boxes void IP ratings and expose electrical equipment to moisture damage. Annual inspection and 5-year preventative gasket replacement prevent costly equipment failures and maintain code compliance.

NEC Article 314: Outlet, Device, Pull, and Junction Boxes

NEC Article 690: Solar Photovoltaic Systems

NEC Article 110.26: Working Space and Access

UL 50: Enclosures for Electrical Equipment – General Requirements

UL 50E: Enclosures for Electrical Equipment – Environmental Considerations

NEMA 250: Enclosures for Electrical Equipment (1000 Volts Maximum)

Before final electrical inspection, verify:

Q: What’s the difference between NEMA and IP ratings for outdoor electrical boxes?

A: NEMA ratings (developed by North American manufacturers) provide broader protection categories including corrosion resistance, construction quality, and environmental factors beyond dust and water. IP ratings specifically quantify dust and liquid ingress protection with precise test methods. Both systems are valid; IP ratings dominate internationally while NEMA remains common in North America. For reference, NEMA 4X roughly corresponds to IP66 protection with added corrosion resistance requirements. Professional solar installers should specify enclosures meeting both standards when available.

Q: Can I use an indoor-rated electrical box outdoors if I add a rain cover?

A: No, this violates electrical codes and creates safety hazards. Outdoor-rated electrical boxes feature UV-stabilized materials preventing degradation, sealed entry systems maintaining IP ratings, proper drainage provisions, and gasket systems designed for weatherproofing. Indoor boxes lack these essential features. Adding a rain cover doesn’t address material degradation, condensation management, or code compliance. Always use properly rated outdoor electrical boxes for exterior solar installations to ensure safety, insurance coverage, and inspection approval.

Q: How do I prevent condensation in outdoor electrical boxes?

A: Implement multiple strategies: install desiccant packs absorbing moisture (replace annually), add breather vents with membrane filters equalizing pressure without allowing water ingress, apply conformal coating to sensitive electronics protecting from humidity, ensure all conduit entries slope away from the box preventing water accumulation, and consider small heater strips in high-humidity coastal or tropical locations. Regular inspection and desiccant replacement are essential. Condensation indicates temperature cycling and humidity exposure, making ongoing moisture management critical for equipment longevity.

Q: What size outdoor electrical box do I need for a typical 10kW residential solar system?

A: For a standard 10kW residential solar system with 2-3 strings, a 16″×14″×8″ outdoor electrical box typically provides adequate space for DC combiner components, circuit protection, surge protection devices, and proper wire management. However, calculate based on your specific equipment: count the number of circuit breakers or fuses required, SPD size, and wire management needs, then add 30-40% for installation ease and future modifications. Always verify NEC Article 314 clearance requirements are met. Larger systems or those with monitoring equipment may require 20″×16″×10″ or larger enclosures.

Q: Are plastic or metal outdoor electrical boxes better for solar installations?

A: Both have advantages depending on application requirements. Metal outdoor electrical boxes (stainless steel or aluminum) offer superior heat dissipation for high-power equipment, maximum physical security against vandalism, professional appearance, and 25+ year durability, making them ideal for commercial and utility-scale installations. Polycarbonate or fiberglass boxes excel in corrosive environments (coastal salt spray, industrial chemicals), weight-sensitive applications, installations requiring equipment visibility, and budget-conscious residential projects. Consider equipment heat load, environmental exposure, security requirements, budget, and aesthetic preferences when selecting enclosure material.

Q: How often should outdoor electrical box gaskets be replaced?

A: Inspect gaskets annually during routine solar system maintenance and plan for preventative replacement every 5 years regardless of apparent condition. Replace immediately if you notice compression set (permanent indentation), cracking, hardening, or loss of elasticity. UV exposure, temperature cycling, and door opening frequency accelerate gasket degradation. In harsh environments (extreme heat, cold, or coastal salt spray), inspect more frequently and replace at first signs of deterioration. Failed gaskets compromise IP ratings and expose electrical equipment to moisture damage. The modest cost of preventative gasket replacement prevents expensive equipment failures and maintains warranty coverage.

Q: Can I mount an outdoor electrical box directly to vinyl or wood siding?

A: Yes, but with critical considerations. Vinyl or wood siding alone doesn’t provide sufficient structural support for heavy outdoor electrical boxes or conduit pull forces. Install solid backing between studs or use ¾” plywood backing plate larger than the enclosure footprint behind the siding. Ensure mounting fasteners penetrate studs or solid backing, not just siding material. Seal the perimeter between enclosure and siding with exterior-grade caulk preventing water intrusion behind siding that could cause rot. For very large or heavy enclosures, consider post-mounting independent of the building structure.

Selecting and installing the appropriate outdoor electrical box is fundamental to solar PV system reliability, safety, and longevity. Professional installers must balance IP rating requirements, material properties, sizing considerations, and installation best practices to ensure 25+ year system performance.

✅ Choose appropriate IP ratings: IP66 for most outdoor solar installations provides dust-tight and high-pressure water resistance. IP65 suffices for covered areas, while IP67 addresses flood-prone locations.

✅ Select materials strategically: Polycarbonate excels in corrosive environments and budget-conscious applications. Metal enclosures (stainless steel, aluminum) deliver superior heat dissipation and durability for commercial projects. Fiberglass suits utility-scale and custom requirements.

✅ Size generously: Calculate for current equipment plus 30-40% for wire management, heat dissipation, and future expansion. Oversized outdoor electrical boxes reduce installation time and accommodate system modifications.

✅ Install properly: Bottom conduit entries, proper sealing, adequate grounding, and accessible mounting height prevent long-term problems. Follow NEC Articles 314 and 690 for code compliance.

✅ Maintain regularly: Monthly visual checks, annual comprehensive inspections, and 5-year preventative seal replacement maintain IP ratings and prevent equipment failures.

✅ Ensure compliance: Use listed enclosures meeting UL, NEMA, and IEC standards. Maintain required clearances and proper labeling per NEC 690.

When combined with properly rated Disyuntores de CC, Fusibles CCy surge protection devices, quality outdoor electrical boxes form the foundation of safe, code-compliant, and reliable solar PV systems delivering decades of trouble-free performance.

SYNODE manufactures a complete range of IP65 and IP66 rated outdoor electrical boxes designed specifically for photovoltaic applications. Our weatherproof distribution boxes feature UV-stabilized polycarbonate and stainless steel construction, pre-installed mounting hardware, optional pre-wired configurations with certified DC protection devices, and comprehensive technical documentation.

All SYNODE outdoor electrical boxes comply with IEC 60529, UL 50/50E, and NEMA standards, providing reliable protection for solar electrical equipment in any climate. With sizes from compact junction boxes to large combiner enclosures, we offer solutions for residential, commercial, and utility-scale solar projects backed by technical support and complete certification documentation.