Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

Understanding comprehensive DC surge protection system design enables effective defense-in-depth strategies for photovoltaic installations. This advanced technology guide examines multi-stage SPD coordination principles, lightning protection zone (LPZ) concepts, energy distribution analysis, and system-level protection architecture. Protection engineers and system designers will find detailed coordination methodologies, zone boundary definitions, and performance optimization strategies for complete PV surge protection systems.

Single-point surge protection using isolated SPD installations represents inadequate approach for modern photovoltaic systems exposed to multiple threat vectors. Lightning strikes inject energy through direct conductor attachment, electromagnetic induction, and ground potential rise mechanisms requiring coordinated protection at multiple system locations. Effective DC surge protection employs systematic defense-in-depth architecture distributing threat mitigation across cascaded protection stages.

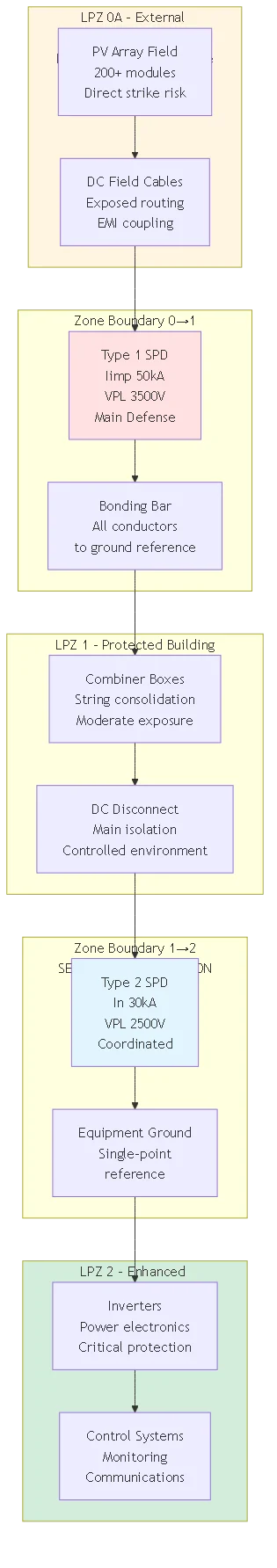

IEC 62305-4 establishes lightning protection zone methodology dividing installations into regions based on electromagnetic threat severity. Each zone boundary crossing requires appropriate protective measures reducing surge voltages and currents to levels acceptable for equipment in destination zone. This systematic approach replaces ad-hoc SPD placement with engineered protection architecture matching threat levels to protection capabilities.

LPZ 0 (External Unprotected): Outermost zone directly exposed to lightning strikes and full electromagnetic field intensity. Photovoltaic arrays mounting on building rooftops or ground-mounted racks occupy LPZ 0A experiencing direct lightning attachment risk. Electromagnetic field intensity in LPZ 0: H ≈ 200 A/m during nearby strikes. Equipment installing in LPZ 0 requires ruggedized construction withstanding harsh environmental exposure and electromagnetic interference.

LPZ 1 (Protected Building Interior): First protected zone where direct lightning strikes prevented through external lightning protection system (air terminals, down conductors, bonding network) but induced surges penetrate via incoming conductors. Electromagnetic field attenuates to H ≈ 20 A/m through magnetic shielding of building structure. Combiner boxes and DC disconnect enclosures typically install in LPZ 1 requiring protection against conducted surges on DC circuits entering from LPZ 0.

LPZ 2+ (Enhanced Protection): Inner zones with progressively better electromagnetic isolation achieved through additional shielding, filtering, and SPD cascading. Inverter interiors and sensitive control electronics occupy LPZ 2 experiencing minimal electromagnetic field exposure (H ≈ 2 A/m) and reduced conducted surge threats. Equipment in LPZ 2 assumes adequate upstream protection limits incoming transients to manageable amplitudes.

| Protection Zone | Threat Level | Typical PV Equipment | Required SPD Type | Livello di protezione della tensione |

|---|---|---|---|---|

| LPZ 0A (External) | Maximum—Direct strikes | PV modules, mounting structures | Type 1 at zone boundary | 2500-4000V |

| LPZ 1 (Building) | Moderate—Induced surges | Combiners, DC disconnects | Type 2 coordinated | 1800-2500V |

| LPZ 2 (Inverter) | Low—Residual transients | Inverters, control systems | Type 2/3 fine protection | 1500-2000V |

Each lightning protection zone boundary crossing requires appropriate surge protective measures reducing electromagnetic threat to levels compatible with equipment in destination zone. The LPZ 0 to LPZ 1 transition represents most critical protection point experiencing maximum surge energy requiring robust Type 1 SPD capability. Calculate minimum SPD rating at this boundary from lightning protection level (LPL) analysis per IEC 62305-2.

Zone boundary SPD installation follows systematic rules:

– Install SPDs as close as possible to boundary crossing minimizing unprotected conductor length

– Bond all conductors (power, data, control) entering zone to common grounding reference at boundary

– Maintain electromagnetic continuity of zone shields through proper conductor routing and shielding termination

– Verify adequate conductor separation or decoupling between SPDs at adjacent zone boundaries

When multiple services enter building at different locations, establish separate zone boundaries at each entry point rather than routing unprotected conductors through building interior to central protection location. This distributed boundary protection prevents surges from propagating through building wiring creating secondary coupling and ground potential rise affecting sensitive equipment distant from entry point.

💡 Approfondimento chiave: Lightning protection zone concept provides engineering framework replacing intuitive SPD placement with systematic protection architecture. Defining clear zone boundaries and specifying appropriate SPD types at each crossing eliminates guesswork from surge protection design ensuring comprehensive threat coverage without unnecessary over-specification.

Multi-stage surge protection distributes total surge energy across multiple SPD locations rather than concentrating entire threat on single device. Upstream SPDs intercept high-energy direct-strike components while downstream SPDs handle residual transients after conductor impedance attenuation. This energy distribution extends SPD service life and provides defense-in-depth protecting against upstream device failures or surges exceeding individual SPD capacity.

Calculate energy distribution using conductor impedance and surge current waveform characteristics. For lightning current with peak Im and rise time tr, voltage developed across conductor inductance L: V = L × (Im/tr). This inductive voltage drop subtracts from upstream SPD clamping voltage before reaching downstream SPD. Example: Upstream Type 1 SPD clamps at 3500V, 20-meter cable provides 30μH inductance, 10kA surge with 1μs rise generates V = 30μH × (10kA/1μs) = 300V drop. Downstream SPD sees 3500V − 300V = 3200V reduced stress.

The energy division ratio depends on SPD voltage protection levels and intermediate conductor impedance. For perfectly coordinated system, upstream SPD diverts 70-90% of surge energy while downstream handles remaining 10-30%. Poor coordination—insufficient conductor separation or improper VPL relationships—causes both SPDs to conduct simultaneously reducing energy division effectiveness and potentially creating voltage reflections damaging protected equipment.

IEC 61643-12 recommends minimum conductor separation between coordinated SPD stages ensuring adequate decoupling for independent operation. Required separation depends on voltage difference between SPD protection levels and expected surge current rise rate. Use formula: Lmin = (VPL_upstream − VPL_downstream) × tr / Im where VPL values are protection levels, tr is current rise time, and Im is maximum expected surge current.

Example calculation for two-stage 1000V system:

– Upstream Type 1: VPL = 3500V

– Downstream Type 2: VPL = 2800V

– Expected surge: Im = 20kA, tr = 8μs (8/20μs waveform)

– Required inductance: Lmin = (3500V − 2800V) × 8μs / 20kA = 700V × 8μs / 20kA = 280nH

– At 1.5μH/meter typical cable inductance: minimum separation = 280nH / 1.5μH/m ≈ 187 meters

Wait, this calculation seems off. Let me recalculate:

Actually, the proper formula should be: Lmin = (VPL_up – VPL_down) / (dI/dt), where dI/dt = Im/tr

Lmin = (3500V – 2800V) / (20kA/8μs) = 700V / 2.5kA/μs = 280μH

At 1.5μH/meter: separation = 280μH / 1.5μH/m ≈ 187 meters – this is impractically long!

Let me use the more practical approach: For 8/20μs waveform, typical rise di/dt ≈ 10kA/μs for Im = 20kA.

Lmin = (VPL_up – VPL_down) / (di/dt) = 700V / 10kA/μs = 70μH minimum

At 1.5μH/m: separation = 70μH / 1.5μH/m ≈ 47 meters practical minimum.

However, IEC 61643-12 simplified recommendation: minimum 10 meters provides approximately 15μH adequate for most residential/commercial applications. Larger utility-scale systems naturally provide 50-200 meters separation delivering 75-300μH ensuring excellent coordination with substantial margin.

When physical separation is insufficient, install discrete decoupling inductors between SPD stages. Line reactors rated 15-50μH with current capacity matching circuit requirements provide equivalent coordination in compact installations. These inductors must handle continuous system current plus short-duration surge currents without saturation degrading coordination effectiveness.

| Conductor Separation | Typical Inductance | Coordination Quality | Applicazione |

|---|---|---|---|

| <5 meters | <7.5μH | Poor – Risk of coordination failure | Not recommended—add inductor |

| 10-15 meters | 15-22μH | Acceptable – Minimum per IEC | Residential, compact commercial |

| 20-50 meters | 30-75μH | Good – Reliable coordination | Standard commercial systems |

| >100 meters | >150μH | Excellent – Natural isolation | Utility-scale, distributed arrays |

⚠️ Importante: Inadequate SPD coordination causes both upstream and downstream devices to conduct simultaneously creating current oscillations and voltage reflections. This uncoordinated operation may actually worsen equipment protection compared to properly selected single-stage SPD by producing higher transient voltages at protected equipment terminals than either SPD would deliver alone.

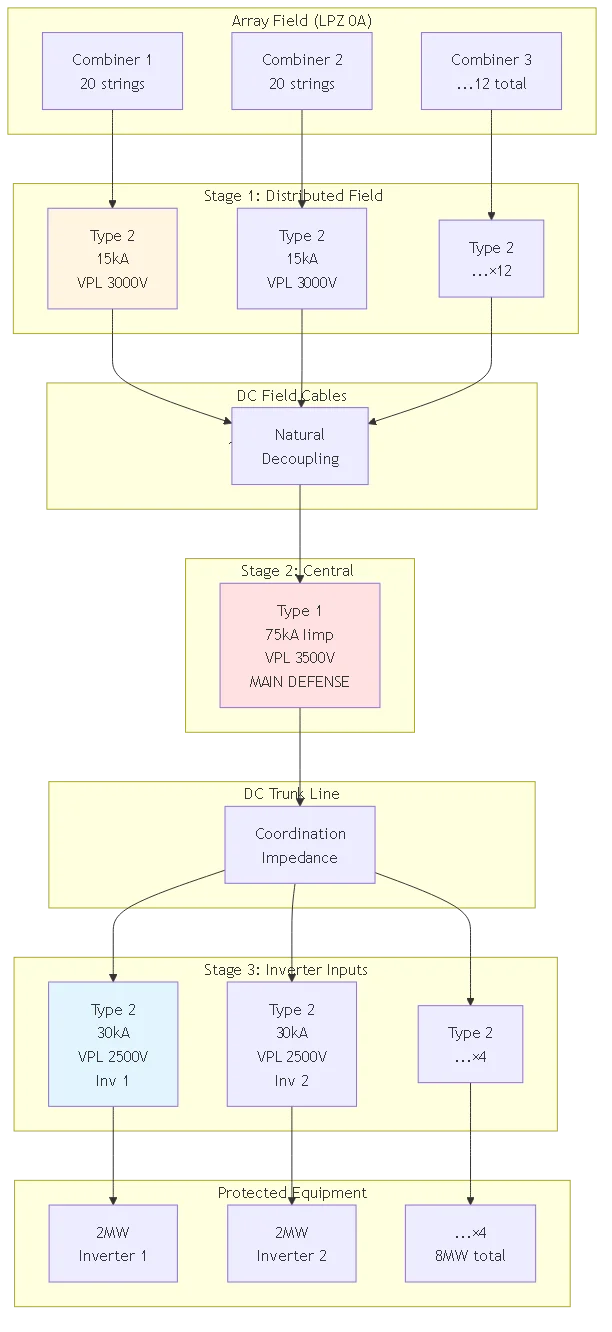

Utility-scale and critical photovoltaic installations benefit from three-stage SPD topology maximizing protection reliability through redundant defense layers. This architecture installs primary protection at array origins (Stage 1), secondary protection at main combiners or recombiners (Stage 2), and tertiary protection at individual inverter inputs (Stage 3). Each stage intercepts appropriate surge components for its location creating comprehensive defense-in-depth.

Stage 1 – Array Field Protection:

Install Type 2 SPDs (In = 15-20kA) at individual string combiner locations throughout array field. These distributed SPDs intercept string-level surges from direct strikes to specific array sections preventing energy coupling onto parallel strings through common DC infrastructure. Stage 1 spacing: typically 20-50 meters between combiners providing natural isolation between adjacent combiner SPDs.

Stage 2 – Central Collection Protection:

Install robust Type 1 SPDs (Iimp = 50-100kA) at central collection point (main recombiner or array field combiner) where all string outputs consolidate before routing to inverter station. Stage 2 represents maximum surge energy concentration requiring highest SPD capability handling combined threats from entire array field. Separation from Stage 1: 100-500 meters typical in large installations.

Stage 3 – Inverter Input Protection:

Install Type 2 SPDs (In = 30-40kA) at each inverter DC input providing final protection stage for sensitive power electronics. Stage 3 SPDs handle residual transients bypassing upstream protection or induced voltages on inverter DC input cables. Separation from Stage 2: 15-50 meters minimum depending on facility layout.

Effective multi-stage surge protection requires integrated grounding architecture bonding all SPD installation points to common low-impedance grounding electrode system. Poor grounding coordination creates ground loops circulating surge currents through equipment chassis potentially causing damage despite presence of SPDs. Design grounding system as essential protection element deserving equal engineering attention as SPD selection.

Single-Point Ground Reference:

Establish designated grounding reference point (typically main service entrance or central equipment ground bus) where all grounding electrode conductors terminate. All SPD locations throughout facility bond to this reference through radial grounding conductors avoiding multiple parallel ground paths creating circulating currents. Single-point reference ensures all SPDs share common ground potential during surge events enabling coordinated operation.

Grounding Electrode System:

IEC 62305 recommends grounding electrode resistance <10Ω for lightning protection systems with <1Ω preferred for sensitive electronic installations. Achieve low resistance through multiple bonded ground rods (minimum 3 meters deep, 6 meters spacing), concrete-encased electrodes (foundation rebar), ground grids (copper mesh under equipment), or combination electrode systems. Test electrode resistance annually verifying performance hasn’t degraded through corrosion or soil condition changes. Bonding and Equipotential Planes:

Bond all metallic infrastructure (array frames, conduit systems, equipment chassis, cable trays, structural steel) to grounding electrode system creating equipotential plane preventing voltage differences during surge events. Use bonding conductors minimum 6 AWG copper with compression or exothermic weld connections—avoid bolted connections subject to loosening and corrosion. Equipotential bonding reduces ground potential rise (GPR) effects that can damage equipment even with properly rated SPDs.

Advanced surge protection leverages hybrid element designs combining complementary technologies optimizing response speed, energy capacity, and voltage clamping characteristics. Metal oxide varistor (MOV) + gas discharge tube (GDT) hybrids deliver GDT high-current capability (100kA+) with MOV fast response preventing voltage overshoot during GDT ionization delay. These hybrids suit primary protection locations (LPZ 0→1 boundaries) requiring maximum energy handling.

Staged Hybrid Response:

1. Surge arrival triggers fast MOV conduction (response <50ns) providing initial voltage limiting 2. Rising surge current causes GDT ionization once voltage reaches breakdown threshold (~500-1000V) 3. GDT arc formation diverts majority of surge current (tens of kA) away from MOV 4. MOV continues limiting residual voltage during GDT conduction maintaining tight clamping 5. After surge passes, GDT deionizes and MOV returns to high-impedance standby state

Silicon avalanche diode (SAD) + MOV hybrids optimize protection for sensitive equipment locations requiring tightest possible voltage clamping. SAD provides sub-nanosecond response and precise voltage limiting (1.5-1.8× MCOV) while MOV handles bulk energy absorption. These premium hybrids cost 40-60% more than MOV-only devices but deliver superior protection for expensive inverter power electronics where voltage tolerance margins are minimal.

Next-generation active surge protection employs semiconductor switching circuits achieving voltage clamping approaching theoretical limits. Silicon-controlled rectifiers (SCRs) or insulated-gate bipolar transistors (IGBTs) activate within microseconds upon detecting surge voltage rise, short-circuiting surge current to ground through low-impedance path. Active clamping achieves VPL 20-30% lower than equivalent passive varistor devices significantly improving equipment protection margin.

Active SPD benefits include precise voltage control independent of surge current magnitude, no degradation from repeated surge exposure (unlike MOVs consuming material with each event), and remote monitoring capabilities reporting device status and surge event characteristics. Disadvantages: higher cost ($800-1500 vs $300-600 for passive), complex electronics requiring auxiliary power, and potential failure modes not present in simple passive devices.

Consider active SPD technology for ultra-sensitive applications—data centers, medical facilities, precision manufacturing—where equipment damage from inadequate voltage clamping exceeds protection system cost. Standard photovoltaic installations rarely justify active protection expense except for critical utility-scale projects where brief inverter outages cost tens of thousands in lost revenue.

Verify multi-stage SPD coordination through surge current distribution analysis calculating expected current division between parallel protection paths. Use nodal analysis or SPICE simulation modeling distributed SPD system as network of voltage-dependent resistances (representing SPDs) connected through inductive impedances (cable inductance). This analysis reveals whether upstream SPDs actually handle expected energy or downstream SPDs conduct prematurely indicating coordination failure.

Simplified two-stage analysis using voltage-current characteristics:

– Upstream SPD voltage: V1 = f1(I1) where f1 is upstream SPD I-V curve

– Downstream SPD voltage: V2 = f2(I2) where f2 is downstream SPD I-V curve

– Coupling impedance voltage drop: VL = L × dI/dt

– Voltage relationship: V1 = V2 + VL during surge event

For proper coordination, upstream SPD conducts first when V1 reaches its threshold while V2 remains below downstream threshold. Calculate critical coupling inductance Lcrit ensuring coordination: Lcrit ≥ (Vthreshold_downstream − Vthreshold_upstream) × tr / Isurge. If actual installation inductance < Lcrit, downstream SPD may conduct prematurely causing coordination failure.

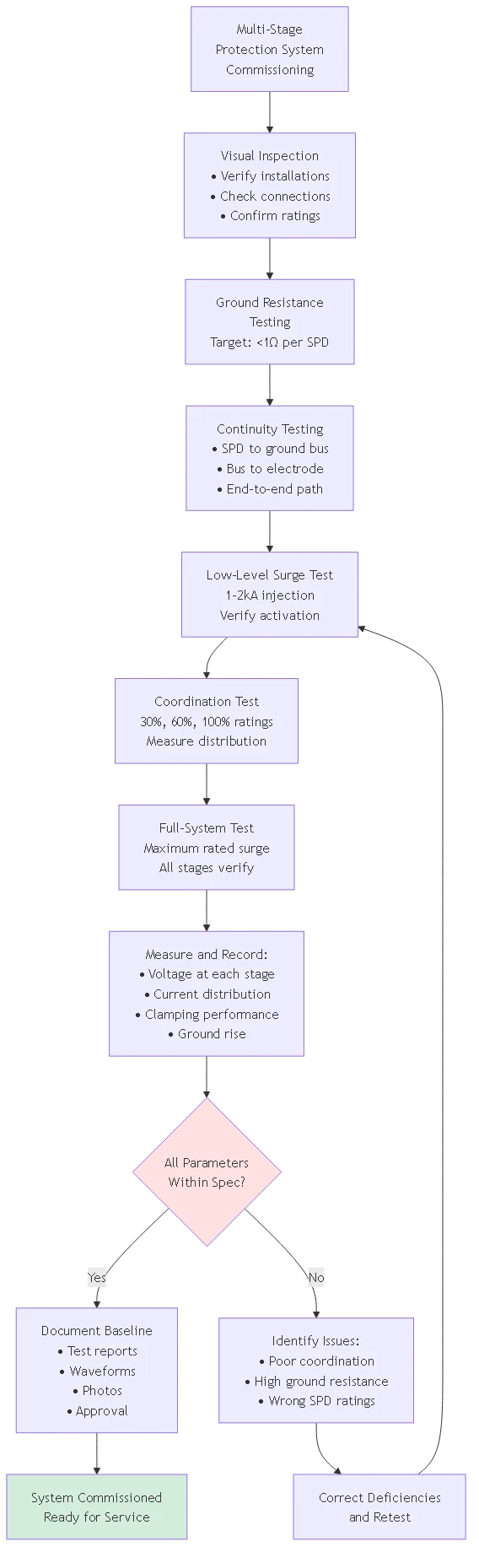

Commission multi-stage protection systems using portable surge generators simulating lightning waveforms verifying proper coordination before actual surge events occur. Standard testing injects 8/20μs or 10/350μs current pulses at specified amplitudes monitoring voltage appearing at each protection stage and at protected equipment terminals. Testing reveals coordination deficiencies, inadequate ground connections, or SPD specifications mismatched to actual system requirements.

Recommended test sequence:

1. Initial continuity testing: Verify SPD ground path resistance <1Ω from each device to grounding electrode 2. Low-level surge injection: 1-2kA test current at each stage verifying SPD activation and voltage clamping

3. Coordination verification: Staged testing at 30%, 60%, 100% of SPD ratings confirming proper energy distribution

4. Full-system testing: Maximum rated surge at primary protection verifying downstream stages don’t exceed limits

5. Documentation: Record measured voltages, currents, and clamping performance for baseline comparison

Document commissioning results establishing performance baseline for future periodic testing. Annual testing using same protocols detects SPD degradation allowing proactive replacement before failures occur. Many specifications require witnessed surge testing by owner’s representative or authority having jurisdiction validating protection system meets design requirements before final acceptance.

Multi-stage surge protection installs coordinated SPD devices at multiple system locations creating defense-in-depth architecture rather than relying on single-point protection. Stage 1 typically protects at array origins intercepting direct-strike energy, Stage 2 at main combiners handling consolidated threats, and Stage 3 at inverter inputs providing final defense for sensitive electronics. This cascaded approach distributes total surge energy across multiple devices rather than forcing single SPD to absorb entire threat.

Multi-stage systems deliver superior reliability through redundancy—upstream SPD failure doesn’t eliminate all protection since downstream devices continue functioning. Distributed protection also handles multiple simultaneous threats—lightning striking array field while induced surge appears on utility connection—requiring protection at multiple locations operating independently. The staged energy distribution extends individual SPD service life by preventing any single device from experiencing maximum system exposure repeatedly.

Single-stage protection remains acceptable for small residential systems (< 10kW) in moderate-exposure locations where cost optimization is priority and threat assessment confirms low lightning risk. However, commercial systems (>50kW), utility-scale installations, and critical applications benefit from multi-stage investment justifiable through equipment protection, reliability improvement, and insurance premium reductions often available for enhanced protection systems.

Calculate minimum separation distance ensuring adequate decoupling between coordinated SPD stages using: Lmin = (VPL_upstream − VPL_downstream) / (di/dt_max) where VPL values are voltage protection levels and di/dt is maximum expected surge current rise rate. For typical PV system with upstream VPL = 3500V, downstream VPL = 2800V, and di/dt = 10kA/μs: Lmin = 700V / 10kA/μs = 70μH minimum inductance.

Convert inductance to physical distance using typical DC cable inductance 1.5μH/meter: required separation = 70μH / 1.5μH/m ≈ 47 meters minimum. However, IEC 61643-12 simplified recommendation specifies 10 meters minimum (15μH) as practical guideline adequate for most installations. Larger commercial and utility-scale systems naturally provide 50-200 meters separation between array field, main combiner, and inverter station locations ensuring excellent coordination with substantial margin.

When physical layout prevents adequate natural separation, install discrete decoupling inductors artificially creating required impedance. Line reactors rated 15-50μH handling continuous DC current plus short-duration surge currents provide equivalent coordination in compact installations. These inductors must exhibit low DC resistance (<1mΩ) minimizing power losses and withstand system voltage without insulation failure.

Lightning protection zones (LPZ) per IEC 62305-4 divide installations into regions based on electromagnetic threat severity. LPZ 0A represents external unprotected environment exposed to direct strikes and full electromagnetic field intensity where PV arrays install. LPZ 1 encompasses protected building interior where direct strikes prevented but induced surges penetrate. LPZ 2+ represents inner zones with progressively better isolation for sensitive equipment.

Each zone boundary crossing requires appropriate SPD reducing surge amplitudes to levels acceptable for equipment in destination zone. LPZ 0→1 boundary demands robust Type 1 SPD capability handling partial direct-strike current that may appear at building entry points. LPZ 1→2 boundary uses coordinated Type 2 SPD addressing attenuated surges having passed through upstream protection and conductor impedance. Equipment insulation ratings must exceed SPD voltage protection levels at zone boundary where device installs.

The LPZ concept provides systematic framework replacing intuitive SPD placement with engineered protection architecture. Define clear zone boundaries matching facility electrical layout, identify equipment locations within zones, and specify SPDs at each boundary crossing appropriate for incoming threat level and destination zone sensitivity. This methodology ensures comprehensive protection without gaps while avoiding unnecessary over-specification at locations with lower threat exposure.

Grounding system quality directly affects SPD performance—high grounding impedance creates additional voltage drop during surge diversion potentially allowing protected equipment to see voltages exceeding insulation ratings despite properly rated SPDs. Calculate total voltage at protected equipment: Vtotal = VSPD_clamp + (Zground × Isurge). For SPD with 3000V protection level and 2Ω ground impedance diverting 20kA surge: Vtotal = 3000V + (2Ω × 20kA) = 43,000V—catastrophic overvoltage caused by inadequate grounding!

IEC 62305 recommends grounding electrode resistance <10Ω for lightning protection with <1Ω preferred for sensitive installations. Achieve low resistance through multiple bonded ground rods (minimum 6 meters spacing, 3 meters depth), concrete-encased electrodes in foundation, ground grids under equipment areas, or combination electrode systems. Test grounding resistance annually using fall-of-potential method or clamp-on ground resistance testers verifying performance hasn’t degraded through corrosion or soil condition changes.

Beyond static resistance, ground system inductance also affects high-frequency surge performance. Long single-conductor ground leads exhibit significant inductance (300-500nH/meter) creating voltage drop proportional to surge current rate of change: VL = L × (di/dt). For 10-meter ground conductor (4500nH) with 10kA/μs surge: VL = 4500nH × 10kA/μs = 45,000V! Minimize ground lead length (<300mm ideal) and use multiple parallel paths reducing combined inductance improving high-frequency surge diversion.

Yes—retrofitting additional SPD stages to existing single-stage protection improves overall system protection without requiring complete replacement. Common retrofit scenario: existing Type 2 SPD at inverter input upgraded with new Type 1 SPD at main array combiner creating two-stage coordinated protection. Verify adequate conductor separation (minimum 10 meters) between existing and new SPD locations ensuring proper coordination.

Retrofit coordination analysis requires measuring or estimating existing SPD voltage protection level and selecting new upstream device with appropriately higher VPL. If existing inverter SPD specifies 2500V VPL, retrofit upstream SPD should specify 3000-3500V VPL ensuring proper staging. Document existing SPD specifications before retrofit—if information unavailable, portable surge testing can measure actual protection level providing data for retrofit design.

Retrofit installations benefit from modern SPD monitoring technology unavailable when original system commissioned. Specify new upstream SPDs with integrated monitoring providing remote status indication, surge event counting, and remaining capacity estimation. Connect monitoring to building management system enabling automated alerts for SPD degradation or failure allowing proactive maintenance preventing protection loss.

Multi-stage surge protection systems require quarterly visual inspection checking status indicators at all SPD locations verifying green “healthy” indication without failure flags. Visual inspection takes 15-30 minutes per site and catches obvious failures before they compromise protection. Document inspection dates and device status in maintenance log creating historical record supporting warranty claims or insurance investigations after surge events.

Annual comprehensive testing using portable surge generators verifies protection performance hasn’t degraded below acceptable thresholds. Inject test currents at 30-50% of SPD ratings measuring voltage protection level at each stage confirming coordination remains effective. Compare results against commissioning baseline—VPL degradation >10% or leakage current increase >100% indicates SPD approaching end of life requiring replacement. Annual testing costs $500-2000 depending on system complexity and technician travel but prevents far costlier equipment failures.

After major thunderstorm events passing within 5km of installation, perform special inspection checking all SPD status indicators and looking for signs of surge activation (indicators may show temporary activation then reset). Storms causing widespread electrical disturbances likely delivered surges to protection system requiring verification all devices survived without damage. Proactive post-storm inspection catches surge-weakened SPDs before subsequent events cause complete failures leaving system unprotected.

Comprehensive three-stage surge protection for commercial 100kW installation costs $3,000-8,000 total including devices, installation labor, and commissioning testing. Stage 1 (field combiners): $300-600 per combiner × 4 locations = $1,200-2,400. Stage 2 (main recombiner): $800-1,500 for Type 1 SPD plus installation = $1,200-2,200. Stage 3 (inverter inputs): $400-700 per inverter × 2 units = $800-1,400. Installation labor and testing: $800-2,000.

Utility-scale multi-megawatt installations scale proportionally: $5,000-15,000 per megawatt for comprehensive protection. For 10MW system: total protection investment $50,000-150,000. This represents 0.5-1.5% of total project capital cost ($10-12M typical) but protects against surge damage potentially costing hundreds of thousands in equipment replacement and millions in lost revenue during extended repair periods.

Compare protection investment against potential losses: single unprotected lightning strike damaging 2MW central inverter costs $200,000 equipment plus $50,000-100,000 lost revenue during 2-3 week replacement period. The comprehensive protection investment ($15,000) pays for itself after preventing single major damage event—subsequent protection against hundreds of surge events over 25-year system lifetime provides extraordinary return on investment.

Comprehensive DC surge protection system design requires systematic engineering approach integrating lightning protection zone concepts, multi-stage SPD coordination, and grounding system architecture. Understanding IEC 62305 zone methodology, energy distribution principles through cascaded protection, and verification testing protocols enables engineers to design defense-in-depth protection for photovoltaic installations exceeding capabilities of single-point SPD installations.

Punti di forza:

1. Lightning protection zone (LPZ) framework divides installations into threat severity regions requiring appropriate SPD types at each zone boundary crossing

2. Multi-stage SPD coordination distributes surge energy across cascaded devices rather than concentrating entire threat on single protection point

3. Minimum 10-meter conductor separation between stages provides adequate decoupling—utility-scale installations naturally achieve 50-200 meters ensuring excellent coordination

4. Grounding system quality directly affects SPD effectiveness—maintain <1Ω electrode resistance and minimize ground lead inductance through short direct connections 5. Three-stage protection topology (array field + central collection + inverter inputs) provides optimal defense-in-depth for commercial and utility-scale PV systems

Investment in comprehensive multi-stage surge protection ($5,000-15,000 per MW) delivers substantial value protecting multi-million dollar equipment assets and preventing revenue losses from unplanned downtime. The systematic design approach presented here eliminates guesswork from SPD selection ensuring every installation receives appropriate protection matching threat levels to SPD capabilities without unnecessary over-specification.

Risorse correlate:

– How to Wire DC SPD: Installation Diagrams & Grounding

– DC SPD Connection Diagrams: String vs Combiner Placement

– 1000V DC SPD Selection for Utility-Scale Systems

Ready to design comprehensive multi-stage surge protection for your photovoltaic projects? Contact our protection system engineering team for lightning risk assessment, zone boundary definition, multi-stage coordination analysis, and complete protection system specifications optimized for your installation requirements and budget constraints.

Ultimo aggiornamento: november 2025

Autore: Team tecnico SYNODE

Recensito da: Lightning Protection System Design Department