Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Outdoor electrical box covers serve as the primary defense against moisture, dust, and environmental damage in solar PV installations. A properly selected and installed cover maintains the enclosure’s IP rating, protects internal components from weather exposure, and ensures long-term system reliability. This comprehensive guide explains everything professional installers and electrical engineers need to know about specifying, installing, and maintaining outdoor electrical box covers for solar applications.

Outdoor electrical box covers protect critical connection points in solar PV systems from environmental threats that can cause equipment failure or safety hazards. The cover forms the primary weather barrier, working with gasket seals to maintain the enclosure’s ingress protection rating.

A quality cover does more than simply close the box. It provides UV resistance to prevent material degradation, maintains structural integrity through temperature extremes, and creates a reliable seal that withstands thousands of thermal expansion cycles. For solar installations operating at 600V, 1000V, or 1500V DC, cover failure can expose dangerous voltages while damaging expensive DC circuit breakers and DC SPDs.

💡 Key Insight: The cover is often the weakest point in waterproof box designs. A premium box with a poor-quality cover fails just as quickly as a budget enclosure. Always evaluate cover construction and sealing mechanisms as carefully as the box itself.

Cover selection impacts installation efficiency and long-term maintenance costs. Transparent covers allow visual inspection of internal components without breaking the weather seal. Hinged covers speed up maintenance compared to fully removable designs. Quick-release latches reduce service time while maintaining adequate closing force for proper gasket compression.

Outdoor electrical box covers fall into several categories based on design, material, and attachment method. Understanding these variations helps specify covers appropriate for specific solar PV applications.

Solid covers provide maximum weather protection and UV resistance. Opaque construction prevents internal temperature buildup from direct sunlight while protecting components from photodegradation. Solid covers work best for installations requiring maximum environmental protection but where frequent visual inspection isn’t necessary. These covers typically use polycarbonate or ABS plastic construction.

Transparent covers allow visual inspection without opening the enclosure. Clear polycarbonate construction lets installers verify DC switch-disconnector positions, check indicator lights, and inspect connections without compromising weather sealing. Transparency trades some UV blocking for inspection convenience, making these covers ideal for boxes housing equipment with status indicators.

Hinged covers attach permanently to the box with corrosion-resistant hinges. This design prevents cover loss during maintenance and speeds up service procedures. Continuous piano hinges distribute stress better than individual hinge points, extending service life. Hinged covers suit installations requiring frequent access for monitoring or seasonal maintenance.

Removable covers detach completely from the box for maximum access during installation or major servicing. These covers typically use multiple latch points or screw fasteners. While removable designs provide excellent access, they risk loss during maintenance and require more time to secure properly. Use removable covers primarily for initial installation convenience rather than frequently accessed locations.

⚠️ Important: Never mix covers from different manufacturers with boxes. Even if dimensions appear compatible, gasket profiles and latch mechanisms vary. Mismatched covers compromise IP ratings and may void certifications.

Cover material selection determines UV resistance, impact strength, temperature performance, and long-term durability. Three primary materials dominate outdoor electrical box cover construction for solar applications.

Polycarbonate covers offer superior impact resistance and UV stability for harsh outdoor environments. High-grade polycarbonate maintains clarity and structural integrity through temperature ranges from -40°C to +120°C. UV-stabilized formulations resist yellowing and embrittlement even under intense sun exposure. Polycarbonate costs more than alternatives but delivers best-in-class durability for exposed solar installations.

ABS plastic covers provide good chemical resistance and moderate UV stability at lower cost. While adequate for many applications, ABS degrades faster than polycarbonate under prolonged UV exposure. The material becomes brittle over time, especially in high-temperature climates. ABS works well for covered installations or boxes mounted in shaded locations where direct sun exposure remains minimal.

Fiberglass-reinforced polyester (FRP) covers deliver excellent strength and flame resistance for industrial applications. FRP maintains dimensional stability across wide temperature ranges and resists most chemicals. However, FRP costs significantly more than polycarbonate while offering similar outdoor performance. Specify FRP covers primarily where flame spread ratings or extreme mechanical strength become critical requirements.

Material selection should account for local climate conditions and expected service life. According to IEC 60670-24, enclosure covers for outdoor electrical installations must withstand specified UV exposure, impact, and temperature cycling tests. Request material certifications documenting compliance with relevant standards.

| Material | UV Resistance | Impact Strength | Temperature Range | Cost |

|---|---|---|---|---|

| Polycarbonate | Excellent (UV8+) | Very High | -40°C to +120°C | $$$$ |

| ABS Plastic | Moderate (UV4-6) | Moderate | -25°C to +80°C | $$ |

| Fiberglass (FRP) | Excellent | Very High | -40°C to +130°C | $$$$$ |

| Metal (Stainless) | N/A (no UV damage) | Excellent | -50°C to +150°C | $$$$$$ |

The gasket between cover and box body creates the actual weather barrier that maintains IP rating. Understanding gasket design and materials ensures proper cover selection and installation practices.

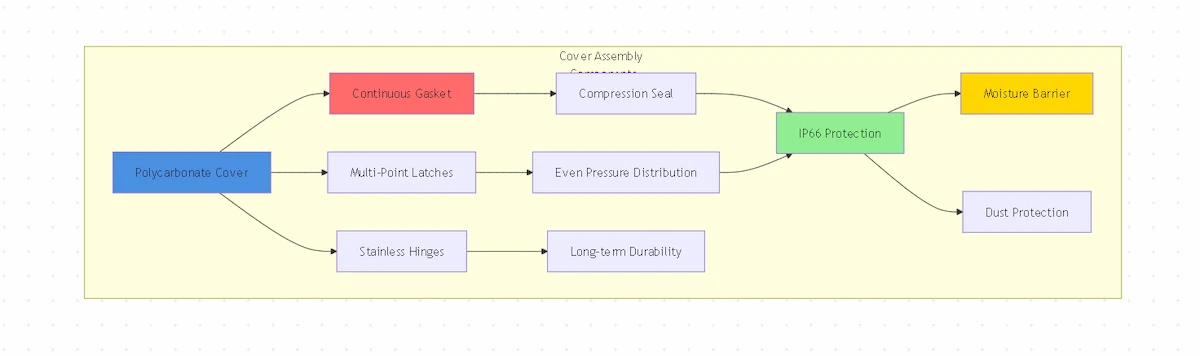

Continuous gaskets run around the entire cover perimeter without breaks or joints. This design provides superior sealing compared to segmented gaskets that can develop gaps at joints. Quality continuous gaskets use closed-cell foam or silicone rubber that maintains compression set resistance through years of thermal cycling. The gasket should have multiple sealing ribs that create redundant barriers against moisture ingress.

Compression requirements determine whether a cover can maintain adequate seal throughout its service life. The gasket must compress sufficiently to fill surface irregularities while retaining enough elasticity to maintain contact pressure. Typical compression ranges from 25-40% of original gasket thickness. Over-compression causes permanent deformation, while under-compression allows moisture penetration.

Material selection affects gasket longevity and performance. Silicone rubber gaskets excel in temperature extremes and UV exposure, maintaining flexibility from -60°C to +200°C. EPDM (ethylene propylene diene monomer) rubber offers excellent weather resistance at moderate cost. Closed-cell foam gaskets work well in mild climates but degrade faster under intense UV exposure.

🎯 Pro Tip: Apply thin silicone grease to new gaskets before first closure. This prevents initial sticking, establishes proper seal, and extends gasket life by reducing friction during thermal expansion. Reapply annually during maintenance inspections.

Gasket replacement typically becomes necessary every 3-5 years depending on climate and UV exposure. Inspect gaskets during annual maintenance for cracking, permanent compression set, or loss of elasticity. Preventive replacement costs far less than component damage from moisture ingress in waterproof distribution boxes.

Latches and hinges directly affect how well a cover maintains gasket compression and weather sealing. These hardware components also determine ease of maintenance and long-term reliability.

Latch designs range from simple snap closures to multi-point locking systems. Single-latch designs often create uneven gasket compression, potentially compromising IP rating at latch-opposite corners. Multi-point latches distribute closing force evenly around the cover perimeter, maintaining consistent seal. Quarter-turn latches provide quick operation while maintaining adequate closing force.

Hardware materials must resist corrosion throughout the installation’s service life. Stainless steel latches and hinges withstand coastal salt air and industrial pollutants. Zinc-plated steel hardware corrodes within months in harsh environments despite lower initial cost. Plastic latches avoid corrosion but may fail mechanically before metal alternatives.

Hinge configurations affect access and durability. Continuous piano hinges distribute stress across the entire hinge line, preventing concentration at individual pivot points. This design delivers longest service life but costs more than discrete hinges. Two-point hinges adequate for small covers but large covers require three or more hinge points to prevent sagging.

Lockable options prevent unauthorized access to critical solar PV protection equipment. Padlock hasps or integrated key locks secure boxes housing DC circuit breakers or manual disconnectors. While adding cost and complexity, locks prevent tampering that could compromise system safety or disable protection devices.

Consider maintenance frequency when selecting latch mechanisms. Frequently accessed boxes benefit from quick-release latches that speed service procedures. Rarely accessed installations can use screw-secured covers that maximize weather sealing and security.

Cover design directly determines whether an electrical box achieves its rated IP protection level. Even premium box construction fails if the cover doesn’t properly maintain the environmental barrier.

IP ratings test the complete assembly—box and cover together—not individual components. The second digit in IP ratings specifies liquid ingress protection relevant to cover performance. IP65 protects against water jets from any direction, suitable for most rooftop solar installations. IP66 withstands powerful water jets for exposed ground-mount systems. IP67 survives temporary immersion in flood-prone locations.

Cover installation practices dramatically affect real-world IP rating performance. IEC 60529 defines standardized test methods for verifying ingress protection, but these tests assume proper installation. Loose latches, damaged gaskets, or missing cable gland seals immediately compromise IP rating regardless of certified performance.

💡 Key Insight: An IP66-rated cover only maintains that protection when properly installed with intact gasket and tight latches. Annual inspection should verify all sealing elements remain functional. One failed component compromises the entire enclosure’s weather protection.

Environmental conditions may require IP ratings higher than minimum code requirements. Coastal installations need IP66 minimum due to driving rain and salt spray. Locations with seasonal flooding require IP67. Covered installations under eaves may function adequately with IP54, though IP65 provides better long-term reliability.

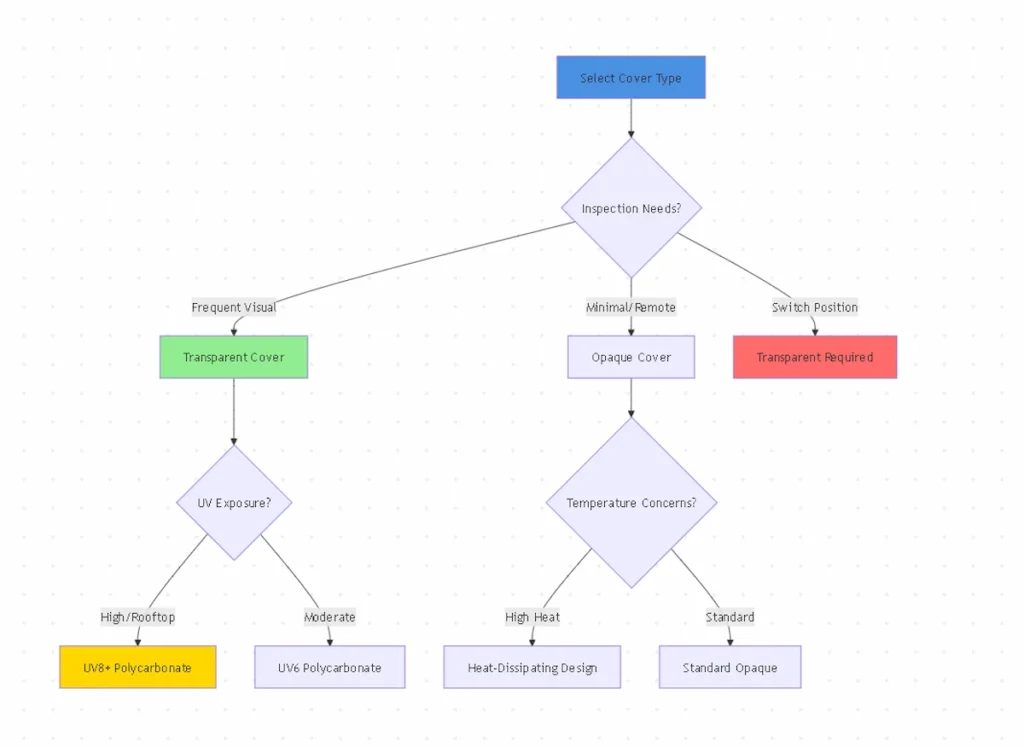

The choice between transparent and opaque covers involves tradeoffs between inspection convenience and environmental protection. Understanding these differences guides appropriate selection for different solar PV applications.

Transparent covers allow visual inspection of internal components without opening the enclosure. Installers can verify DC switch-disconnector positions, check indicator lights on surge protectors, and observe connection conditions. This capability reduces maintenance time and avoids repeatedly breaking weather seals. However, transparency reduces UV blocking and may allow internal temperature buildup.

UV transmission through transparent covers can degrade component labels and accelerate plastic housing deterioration. Quality transparent covers use UV-blocking polycarbonate that filters harmful wavelengths while maintaining visible light transparency. Specify covers with UV400+ blocking to protect internal components while retaining inspection benefits.

Opaque covers provide maximum UV blocking and temperature control. Solid construction prevents direct sunlight from heating internal components, reducing thermal stress. Opaque covers also eliminate concerns about photodegradation of labels and plastic housings. These covers suit installations where visual inspection provides limited value or where temperature control becomes critical.

Tinted covers offer compromise between transparency and protection. Light tinting reduces UV transmission and internal heating while maintaining adequate visibility for status indicator inspection. Gray or bronze tinting typically provides best balance for solar PV applications.

Selection depends on equipment housed within the box. Enclosures with manual disconnectors benefit from transparent covers that confirm switch position without opening. Boxes housing only PV combiner box connections without indicators work well with opaque covers providing maximum environmental protection.

Proper cover installation ensures the enclosure maintains its IP rating and protects internal components throughout the system’s service life. Even quality covers fail when incorrectly installed.

Gasket inspection before installation verifies seal integrity. Examine the gasket for manufacturing defects, damage during shipping, or improper fit in the gasket channel. The gasket should sit evenly in its groove without twists, gaps, or compression. Clean gasket seating surfaces on both cover and box body to remove dust or debris.

Initial closure requires attention to latch engagement sequence. For multi-latch covers, close latches in alternating pattern around the perimeter rather than sequentially. This distributes gasket compression evenly and prevents distortion. Tighten latches until firm resistance indicates proper seal, but avoid excessive force that may damage latch mechanisms.

Cable routing affects cover closure and sealing. Route cables to minimize stress on the cover when closed. Sharp bends near cable glands create pulling force that can distort the cover or compromise gasket seal. Allow adequate cable slack inside the box for natural thermal expansion and contraction.

Mounting orientation impacts water drainage around the cover. While covers should provide weatherproofing from any angle, orienting cable entries downward provides additional protection. This prevents water from pooling around cable glands where capillary action might eventually overcome sealing.

⚠️ Important: Never force covers closed over improperly positioned components or pinched cables. Forced closure may appear to seal initially but creates stress points that fail over time. Reorganize internal components to allow natural cover closure without interference.

Verify all latches engage fully after installation. A latch that appears closed but hasn’t completely engaged will allow moisture ingress despite looking properly secured. Test each latch by gently pulling on the cover—properly engaged latches should show no movement.

Regular cover maintenance preserves weather sealing and extends service life. Establishing an inspection schedule appropriate to local conditions prevents premature failures.

Annual inspections should examine gasket condition, latch function, and material integrity. Look for gasket cracking, permanent compression set, or hardening that reduces flexibility. Test latches for proper engagement and adequate closing force. Inspect cover material for cracks, yellowing (indicating UV damage), or warping from thermal stress.

Cleaning procedures prevent dirt buildup that degrades gasket sealing. Wipe gasket seating surfaces with clean, lint-free cloths during inspections. Remove accumulated dust and debris from cover surfaces. For transparent covers, clean with mild soap solution and soft cloth—avoid abrasive cleaners that scratch polycarbonate.

Gasket lubrication maintains sealing performance between replacement intervals. Apply thin coating of silicone grease to gasket surfaces annually. This prevents drying and cracking while reducing friction during thermal expansion. Avoid petroleum-based lubricants that degrade rubber gaskets.

Hardware inspection catches developing problems before complete failure. Check latch operation for smooth function without binding. Examine hinges for corrosion or wear. Tighten loose fasteners before they allow cover movement that damages gaskets. Replace corroded hardware immediately to prevent failure during severe weather.

| Interval | Inspection Items | Maintenance Tasks | Priority |

|---|---|---|---|

| Annual | Gasket condition, latch function | Clean surfaces, lubricate gasket | Critical |

| Bi-Annual | UV damage, transparent cover clarity | Clean cover, check for cracks | Important |

| 3-5 Years | Gasket elasticity, compression set | Replace gasket preventively | Critical |

| As Needed | Hardware corrosion, latch damage | Replace failed components | Critical |

Post-storm inspection should follow severe weather events. High winds can stress latches and hinges. Driving rain may reveal sealing weaknesses. Hail can crack covers despite impact-resistant materials. Inspect covers after major weather events to catch damage before it progresses to component failure.

Understanding typical cover failures helps diagnose problems quickly and implement effective solutions. Most issues relate to sealing degradation or hardware malfunction.

Moisture inside box despite closed cover indicates gasket failure or cable gland leakage. Systematically inspect the gasket for gaps, permanent compression, or hardening. Check each cable gland by hand-tightening—loose glands are common moisture entry points. Verify drain holes remain clear, as blocked drains can create condensation appearance that mimics leakage.

Warped covers result from thermal stress or improper storage. Polycarbonate naturally expands and contracts with temperature but maintains shape when properly formulated. Visible warping indicates low-quality material or extreme temperature exposure. Warped covers cannot maintain even gasket compression, requiring replacement.

Cracked covers from impact or UV degradation compromise protection immediately. Hairline cracks propagate rapidly under thermal cycling. Replace cracked covers regardless of size—attempting repairs with sealants provides only temporary fixes that fail under weather exposure.

Latch failure prevents adequate gasket compression. Plastic latches may break under repeated operation or UV exposure. Metal latches corrode in coastal environments. Replace failed latches with corrosion-resistant hardware. If latches fail frequently, the cover may be undersized or poorly designed for the application.

🎯 Pro Tip: Keep spare gaskets and common latch components on-site for large solar installations. This minimizes downtime when cover maintenance reveals component replacement needs. Gaskets and small hardware cost minimal amounts compared to service call expenses.

Yellow or brittle plastic indicates UV degradation despite claimed UV stabilization. This occurs with budget covers using inadequate UV additives. Yellowed covers have lost mechanical strength and will crack under impact or thermal stress. Replace deteriorating covers before they fail completely during severe weather.

Determining when to replace existing covers or upgrade to better alternatives involves evaluating condition, performance, and total cost of ownership.

Replacement triggers include visible cracking, gasket seal failure despite new gaskets, latch malfunction, or significant UV degradation. Any condition preventing the cover from maintaining IP rating requires replacement. While gaskets and hardware can be replaced, cover material degradation necessitates complete cover replacement.

Upgrade considerations arise when existing covers function adequately but better alternatives could reduce maintenance. Upgrading from opaque to transparent covers improves inspection efficiency for boxes requiring frequent monitoring. Replacing quick-release latches with lockable hardware adds security. Converting to UV8-stabilized polycarbonate extends service life in high-UV environments.

Cost-benefit analysis should account for installation labor, not just component costs. Cover replacement requires system shutdown and qualified personnel. If covers need replacement due to age or degradation, upgrading to premium alternatives adds minimal incremental cost compared to labor expenses. The improved reliability and reduced maintenance justify higher material costs.

System-wide replacement makes economic sense for large solar installations when multiple covers approach end of service life. Bulk replacement reduces per-unit labor costs and minimizes repeated system shutdowns. Standardizing on quality covers also simplifies spare parts inventory.

Consider replacement timing relative to other maintenance activities. Replacing covers during scheduled inverter maintenance or system upgrades eliminates additional shutdown costs. Coordinate cover maintenance with DC circuit breaker testing or DC fuse replacement to maximize efficiency.

Outdoor electrical box covers must meet relevant electrical and environmental standards. Understanding these requirements ensures specification of compliant products.

IEC 60529 defines the IP rating system and test methods for enclosures. This standard establishes procedures for verifying liquid and solid ingress protection. Covers must undergo testing as part of the complete enclosure assembly to validate IP ratings.

IEC 60670-24 specifies requirements for boxes and enclosures for electrical accessories including distribution boards. This standard defines mechanical strength, temperature resistance, and UV stability requirements. Covers must meet impact resistance specifications based on IK ratings.

UL 50 (US standard) establishes requirements for enclosures for electrical equipment. UL Type ratings provide similar protection levels as IP ratings. Type 4 and 4X enclosures require covers providing weather resistance and corrosion protection suitable for outdoor installations.

NEC Article 110.3 requires listed or labeled equipment to be installed and used according to instructions included in the listing. This means covers must be used with compatible boxes from the same manufacturer unless specifically rated for universal compatibility.

💡 Key Insight: Certification marks on covers (UL, CE, TÜV) indicate third-party testing verification. Self-certified products without independent testing may not perform as claimed. Always request test reports when specifying covers for critical solar PV applications.

Regional requirements may impose additional standards. European installations require CE marking and compliance with Low Voltage Directive. Australian installations need compliance with AS/NZS standards. Verify local requirements before specifying covers for international projects.

Quality variations among outdoor electrical box covers significantly affect reliability and total cost of ownership. Understanding quality indicators guides purchasing decisions.

Material specifications provide first quality indicator. Request UV stabilization ratings—premium covers specify UV8 (8000+ hours exposure) or higher. Verify temperature range matches or exceeds installation environment. Check impact resistance specifications using IK ratings—IK08 provides adequate protection for most solar installations.

Gasket specifications separate quality products from budget alternatives. Premium covers use medical-grade silicone or EPDM gaskets with documented compression set resistance. Budget covers often use generic foam that compresses permanently within months. Request gasket material specifications and compression set test data.

Hardware quality affects long-term reliability. Stainless steel latches and hinges justify higher costs through extended service life and corrosion resistance. Verify hardware is replaceable rather than molded into the cover—replaceable hardware extends cover usable life significantly.

Certification documentation validates performance claims. Request IP rating test reports from accredited laboratories, not just datasheets claiming ratings. UL, TÜV, or equivalent marks indicate independent verification. Manufacturer self-certification without testing may overstate actual performance.

Warranty terms reflect manufacturer confidence in product durability. Quality covers typically carry 5-10 year warranties against UV degradation and material failure. Short warranty periods or exclusions for UV damage indicate questionable material quality.

🔵 SYNODE Solution: SYNODE waterproof distribution boxes feature UV8-stabilized polycarbonate covers with continuous silicone gaskets and stainless steel hardware. Our covers maintain IP66 rating throughout 10+ year service life with minimal maintenance. Third-party testing verification ensures reliable protection for solar PV applications.

Different solar PV applications require covers optimized for specific requirements. Matching cover characteristics to application ensures optimal performance.

String combiner boxes benefit from transparent covers allowing inspection of DC fuses and SPD status indicators. These boxes require frequent visual verification, making transparent covers worth any premium cost. Specify UV-blocking transparent polycarbonate to protect internal components while maintaining visibility.

DC disconnect boxes absolutely require transparent covers per safety codes. Maintenance personnel must verify switch position before working on equipment. Some jurisdictions require specific labeling visible through transparent covers. Use high-clarity polycarbonate that maintains transparency despite UV exposure.

Inverter input boxes typically house monitoring equipment with status indicators. Transparent covers allow status verification without opening the box. If monitoring occurs remotely without visual inspection needs, opaque covers provide better temperature control near heat-generating inverters.

Surge protection boxes may use opaque covers since SPD status indicators trigger alarms rather than requiring visual monitoring. However, transparent covers simplify troubleshooting when alarms activate. Consider maintenance procedures when selecting between transparent and opaque options.

Rooftop vs. ground-mount locations affect cover selection. Rooftop boxes experience more direct sun exposure, benefiting from maximum UV stabilization. Ground-mount boxes face potential impact from maintenance activity or vandalism, requiring higher impact resistance. Coastal ground-mount installations need maximum corrosion-resistant hardware.

| Application | Cover Type | Material Priority | Key Features |

|---|---|---|---|

| String Combiner | Transparent | UV8 polycarbonate | Status visibility, hinged |

| DC Disconnect | Transparent (required) | High-clarity PC | Position visibility, lockable |

| Inverter Input | Opaque or tinted | Heat resistance | Temperature control |

| Rooftop Boxes | Maximum UV protection | UV8+ polycarbonate | Long-term durability |

| Ground Mount | Impact resistant | IK08+ rating | Vandal resistance |

How often should I replace outdoor electrical box covers?

Cover lifespan depends on material quality and UV exposure intensity. Premium UV8-stabilized polycarbonate covers typically last 10-15 years in standard conditions. Budget ABS covers may require replacement in 5-7 years. Replace covers immediately if cracking, severe yellowing, or warping occurs regardless of age. Gaskets typically need replacement every 3-5 years while covers remain serviceable. Inspect covers annually and replace preventively when UV degradation becomes visible rather than waiting for complete failure.

Can I replace just the gasket without replacing the cover?

Yes, gasket replacement extends cover service life significantly when the cover material remains in good condition. Most quality covers use replaceable gaskets that fit into dedicated grooves. Order replacement gaskets from the original manufacturer to ensure proper fit and material compatibility. Clean gasket channels thoroughly before installing new gaskets. Apply silicone grease to new gaskets before first closure. Gasket replacement costs minimal compared to complete cover replacement and should be part of routine maintenance.

What’s the difference between IP65 and IP66 covers?

Both IP65 and IP66 provide dust-tight protection (first digit 6), but differ in water resistance. IP65 protects against water jets from standard nozzle (6.3mm) at 12.5 liters/minute from any direction. IP66 withstands powerful jets from 12.5mm nozzle at 100 liters/minute. Practically, IP66 handles driving rain and pressure washing better than IP65. For exposed rooftop solar installations, IP65 suffices. Coastal locations with severe weather or ground-mount systems needing periodic cleaning should specify IP66 covers for additional protection margin.

Do transparent covers reduce UV protection for internal components?

Quality transparent covers use UV-blocking polycarbonate that filters harmful UV wavelengths while allowing visible light transmission. Specify covers with UV400+ blocking to protect internal components. However, transparent covers do allow more heat buildup than opaque alternatives. This matters for temperature-sensitive components or boxes mounted in full sun. Tinted transparent covers provide compromise between visibility and temperature control. For DC SPDs and DC circuit breakers with status indicators, the inspection benefits of transparency typically outweigh any heat concerns.

Can I use covers from different manufacturers on my existing boxes?

Mixing covers and boxes from different manufacturers usually compromises IP rating even when dimensions appear compatible. Gasket profiles, latch mechanisms, and mounting details vary between manufacturers. IEC 60529 testing certifies complete assemblies, not individual components. Using mismatched covers typically voids both box and cover warranties. Only use covers specifically rated for universal compatibility or from the original box manufacturer. The small cost savings from using available covers isn’t worth the risk of moisture damage to expensive protection equipment.

How do I know if my cover has adequate UV stabilization?

Request UV stabilization specifications from the manufacturer—quality covers specify UV8 (8000+ hours) or higher ratings per ASTM standards. Visual inspection provides clues: yellowing indicates UV degradation even in covers claiming UV resistance. Brittleness when pressed suggests material breakdown. Quality manufacturers provide UV testing data and long-term outdoor exposure test results. Budget covers often list only “UV stabilized” without specific ratings. For critical solar PV applications, specify covers with documented UV8+ ratings and third-party test verification.

What causes covers to warp and how can I prevent it?

Cover warping results from thermal stress in poor-quality materials or extreme temperature cycling. Polycarbonate naturally expands with heat but quality formulations return to original shape when cooled. Warping indicates inadequate material grade or UV degradation that changes material properties. Prevent warping by specifying premium UV-stabilized materials rated for your climate’s temperature extremes. Avoid dark-colored covers in high-temperature climates as they absorb more heat. Ensure adequate ventilation around boxes to minimize internal temperature buildup. Once warped, covers cannot maintain even gasket compression and require replacement.

Outdoor electrical box covers serve as the primary defense protecting solar PV electrical connections from environmental damage. Proper cover selection based on application requirements, material quality, and IP rating ensures reliable weather protection throughout system service life.

Premium covers with UV8-stabilized polycarbonate construction, quality silicone gaskets, and corrosion-resistant hardware deliver superior total cost of ownership compared to budget alternatives. The small additional upfront cost prevents expensive component failures and reduces lifetime maintenance requirements significantly.

Professional installation practices—proper gasket maintenance, correct latch engagement, and appropriate mounting orientation—determine whether covers maintain their IP ratings in real-world conditions. Regular inspection and preventive maintenance extend cover service life while catching potential problems before they cause equipment damage.

Key Takeaways:

SYNODE manufactures professional-grade outdoor electrical box covers engineered specifically for demanding solar PV applications. Our covers feature UV8-stabilized polycarbonate construction, continuous silicone gaskets, and stainless steel hardware for reliable long-term performance.

SYNODE Cover Advantages:

Our covers integrate seamlessly with complete SYNODE protection systems including DC circuit breakers, DC fuses, DC SPDs, and DC switch-disconnectors. CE, TÜV, and UL certifications ensure global compliance for installations in 50+ countries.

Ready to specify covers for your solar project? Contact SYNODE’s technical team for application-specific recommendations, compatibility verification, and competitive quotations. We support solar professionals worldwide with reliable products and expert guidance.