Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

If you’ve ever opened that gray metal box on your wall to flip a tripped breaker, you’ve encountered an electrical distribution box. This essential component serves as the central hub where electricity enters your home or building and gets safely distributed to different circuits throughout the property.

Understanding what an electrical distribution box is and how different panel types work is crucial for homeowners, facility managers, and anyone involved in electrical system planning. Whether you’re planning a renovation, troubleshooting electrical issues, or simply want to understand your building’s electrical infrastructure, knowing the basics can save you time, money, and potentially prevent safety hazards.

This guide breaks down everything you need to know about electrical distribution boxes in plain English. We’ll explain what they are, the different panel types you’ll encounter, NEC 408 requirements that govern their installation, and common applications for each type.

💡 Quick Answer: An electrical distribution box is a metal enclosure that houses circuit breakers or fuses, distributing incoming electrical power to individual circuits while providing overcurrent protection and a safe disconnection point for maintenance.

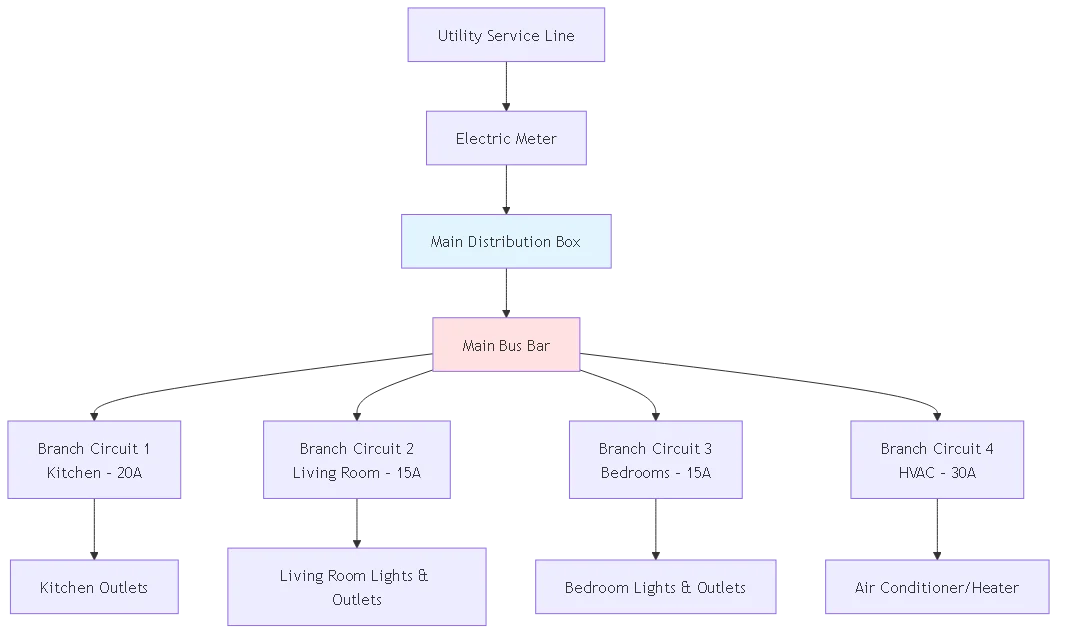

An electrical distribution box is the central control point for your building’s electrical system. Think of it as a traffic control center for electricity—power comes in through one main line, and the distribution box divides it into multiple smaller circuits that supply different areas of your home or building.

Electrical: Refers to the alternating current (AC) or direct current (DC) power system the box controls.

Distribution: Describes the box’s primary function—taking incoming power and distributing it to multiple branch circuits that serve different loads like lights, outlets, appliances, and equipment.

Box: The physical metal enclosure that houses all the components, providing protection from physical damage, environmental factors, and preventing accidental contact with live electrical parts.

The electrical distribution box serves several critical functions in your electrical system. At its core, it’s designed to make electrical power safe and manageable throughout your building.

Here’s what happens inside an electrical distribution box:

1. Receives incoming power: The main electrical service line connects to the distribution box, bringing power from the utility company or another source.

2. Divides power into circuits: The box splits this incoming power into separate circuits, each protected by its own circuit breaker or fuse.

3. Provides overcurrent protection: Each circuit breaker automatically disconnects power if too much current flows through a circuit, preventing wire overheating and fire hazards.

4. Offers safe disconnection: Circuit breakers give you a safe way to turn off power to specific circuits for maintenance, repairs, or emergencies.

Real-World Analogy: Think of an electrical distribution box like a post office sorting facility. Mail (electricity) arrives in bulk from one source, gets sorted into different routes (circuits), and each route has size limits (breaker ratings) to prevent overloading. If someone tries to send too much through one route, it gets stopped automatically.

Every building with electrical service needs a properly installed electrical distribution box to meet National Electrical Code (NEC) Article 408 requirements. These aren’t optional guidelines—they’re enforceable standards that protect lives and property.

Real Example: During a home inspection, the inspector checks that your distribution box meets current code requirements. A non-compliant installation can delay real estate transactions, increase insurance costs, or result in mandatory upgrades.

Without circuit breakers in a distribution box, electrical faults or overloads would cause wires to overheat until they start fires. The distribution box provides the first line of defense against this danger.

Circuit breakers detect overcurrent conditions within milliseconds and automatically disconnect faulty circuits before wires reach dangerous temperatures. This protection operates 24/7 without any action required from you.

Why codes require them: NEC 408.3 mandates that all panelboards (the proper term for what most people call distribution boxes) include overcurrent protection for each circuit. This requirement has prevented countless fires and electrical accidents.

A properly labeled distribution box lets you quickly identify and control individual circuits. Need to turn off power to a bedroom for electrical work? Simply flip the appropriate breaker rather than shutting down your entire building.

Modern electrical distribution boxes include directory spaces where you can list what each circuit controls. This organization becomes invaluable during emergencies, renovations, or routine maintenance.

Distribution boxes come in various sizes with different numbers of circuit positions. Choosing the right size during installation provides room for future expansion as your electrical needs grow.

Adding a home office, workshop, or electric vehicle charger often requires new dedicated circuits. A distribution box with spare capacity makes these additions straightforward without needing to replace the entire panel.

Modern electrical distribution boxes accommodate specialized protection devices like GFCI (Ground Fault Circuit Interrupter) and AFCI (Arc Fault Circuit Interrupter) breakers. These advanced protections have become required in specific locations throughout residential and commercial buildings.

GFCI protection prevents shock hazards in wet locations like bathrooms and kitchens. AFCI protection detects dangerous arcing conditions that can start fires, now required in most living areas of homes built after 2002.

Understanding how an electrical distribution box functions doesn’t require an engineering degree. The basic operating principle is straightforward: safely divide and protect electrical circuits.

An electrical distribution box combines two essential elements: a distribution system and a protection system. Think of it like a car with both acceleration (distribution) and brakes (protection)—you need both working properly for safe operation.

#### The Distribution System: Power Highway

What it does: Routes incoming electrical power from the main service to individual branch circuits throughout your building.

How it works: Inside the distribution box, you’ll find bus bars—thick metal strips that conduct electricity. The main bus bar connects to your incoming power lines. Individual circuit breakers attach to this bus bar, creating tap-off points for each circuit.

When you turn on a light or appliance, electricity flows from your utility service, through the meter, into the distribution box’s main bus bar, through the appropriate circuit breaker, down the circuit wiring, to your device, and back through the neutral bus bar to complete the circuit.

Real-world analogy: The bus bar system works like a highway with multiple exit ramps. The main highway (bus bar) carries all the traffic, while each exit ramp (circuit breaker connection) takes some traffic to specific destinations.

#### The Protection System: Automatic Safety Guardian

What it does: Monitors electrical current on each circuit and automatically disconnects power when dangerous conditions occur.

How it works: Every circuit breaker contains internal mechanisms (thermal or magnetic) that sense current flow. When current exceeds the breaker’s rating—whether from an overload or short circuit—the mechanism trips, physically disconnecting that circuit from the power source.

This happens automatically within milliseconds, fast enough to prevent wires from heating to dangerous temperatures. You’ll hear a distinct “click” when a breaker trips, and the breaker handle moves to the “off” or middle position.

Modern electronic circuit breakers can also detect arc faults (damaged wire insulation causing electrical arcing) and ground faults (current leaking through unintended paths to ground), providing even more comprehensive protection.

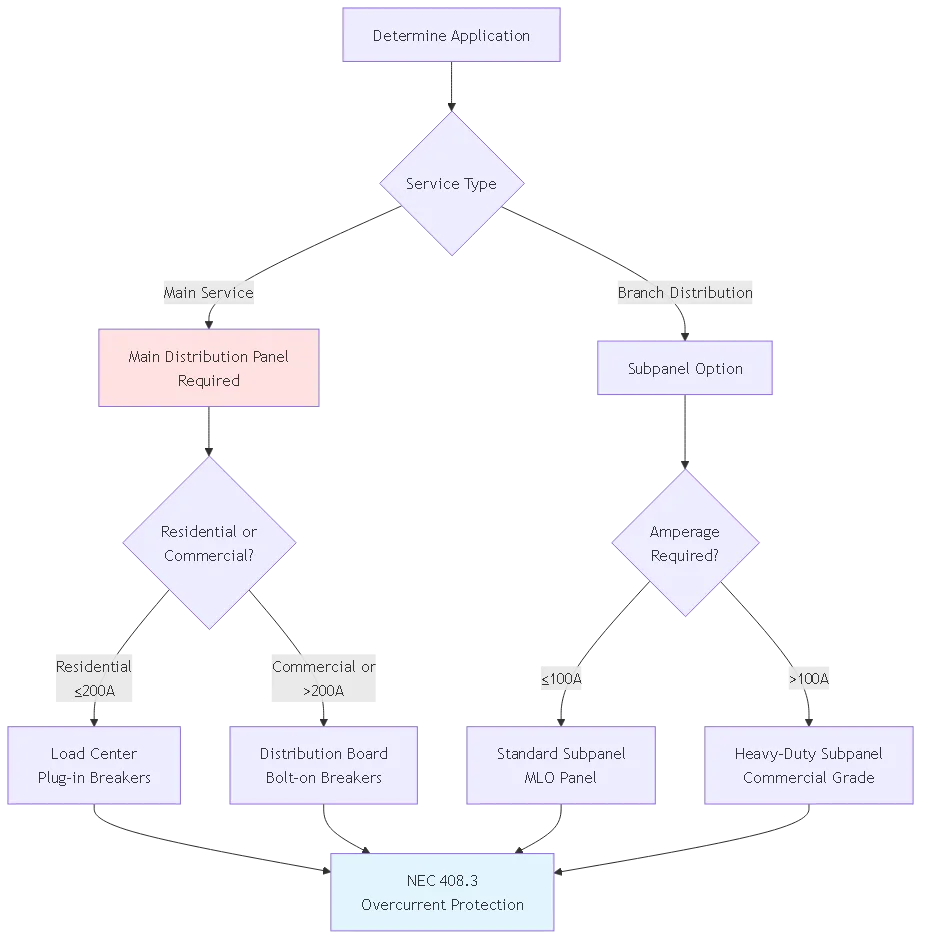

Understanding the different types of electrical distribution boxes helps you identify what you have in your building and what you might need for specific applications. The electrical industry uses specific terminology for different panel types based on their function and location in the electrical system.

Main Distribution Panel (Service Panel)

The main distribution panel is the first distribution point after your electric meter. It receives power directly from the utility service and contains the main disconnect—a large breaker or switch that can shut off all power to your building.

✅ Advantages:

– Contains main disconnect for entire building

– Houses service entrance conductors

– Serves as the primary overcurrent protection point

– Required by code for every electrical service

❌ Disadvantages:

– Limited number of circuit positions (typically 20-42)

– Located at service entrance, which may not be centrally positioned

– Replacing or upgrading requires utility company coordination

Best For: Every building’s primary electrical service connection. Required for code compliance and safety.

Sub-Distribution Panel (Subpanel)

A sub-distribution panel receives power from the main panel through a feeder circuit. It essentially extends the number of available circuits and brings distribution closer to loads in remote areas of large buildings.

✅ Advantages:

– Adds circuit capacity without replacing main panel

– Positions distribution point closer to load centers

– Reduces wire lengths for remote circuits

– Can be added incrementally as needs grow

❌ Disadvantages:

– Cannot disconnect incoming utility service

– Requires proper feeder sizing from main panel

– Neutral and ground must remain separate (unlike main panel)

– Additional cost beyond main panel

Best For: Detached garages, workshops, home additions, large homes, commercial buildings with distributed loads, and situations requiring circuit expansion beyond main panel capacity.

Lighting Panel

Specialized distribution boxes designed primarily for lighting circuits, typically using lower amperage breakers (15-20A) and sometimes including special features like contactor controls for large lighting systems.

✅ Advantages:

– Optimized circuit density for lighting loads

– Can integrate with lighting control systems

– Efficient layout for multiple small circuits

– May include remote switching capabilities

Best For: Commercial buildings, warehouses, parking garages, and large facilities with extensive lighting systems requiring centralized control.

Power Panel (Appliance Panel)

Distribution boxes configured for higher-amperage circuits serving receptacles, equipment, and appliances rather than lighting. These typically include 20-30A breakers and may serve dedicated equipment loads.

✅ Advantages:

– Sized for higher current appliances

– Dedicated circuits prevent interaction between loads

– Organized separation of lighting and power circuits

– Better suited for equipment with high inrush currents

Best For: Commercial kitchens, workshops, industrial facilities, and areas with heavy equipment loads requiring dedicated circuits.

Load Center (Residential Panel)

The term “load center” specifically refers to residential-style distribution boxes with plug-in circuit breakers that clip onto the bus bar. These are the familiar panels you’ll find in most homes.

✅ Advantages:

– Economical for residential applications

– Simple breaker replacement (plug-in design)

– Widely available in various configurations

– Compact size suitable for homes

❌ Disadvantages:

– Lower short-circuit ratings than commercial panels

– Limited to smaller conductor sizes

– Less robust construction than industrial panels

Best For: Single-family homes, townhouses, small apartments, and light commercial applications under 200A service.

Distribution Board (Commercial/Industrial Panel)

Commercial-grade distribution boxes featuring bolt-on circuit breakers, heavier construction, and higher short-circuit ratings. These panels are built to withstand harsher environments and higher fault currents.

✅ Advantages:

– Higher short-circuit withstand ratings (22kA-65kA)

– Bolt-on breakers prevent accidental disconnection

– Accepts larger conductor sizes

– More durable construction

– Better suited for harsh environments

❌ Disadvantages:

– Higher cost than residential load centers

– Requires more installation labor

– Larger physical footprint

Best For: Commercial buildings, industrial facilities, multi-unit residential buildings, and any application requiring service above 200A or higher fault current protection.

In single-family homes, the main electrical distribution box typically installs near where the utility service enters the building. This panel receives power from the meter and distributes it to all household circuits.

Requirements:

– Main breaker sized to match service rating (100A, 150A, 200A typical)

– Minimum 20 circuit positions for modern homes

– GFCI protection for bathrooms, kitchens, outdoor areas

– AFCI protection for bedrooms and most living areas

– Proper grounding electrode connection

Typical Configuration:

A 200A main breaker panel with 30-40 circuit positions serving various loads:

– Lighting circuits: 15A breakers

– General receptacle circuits: 20A breakers

– Kitchen small appliance circuits: 20A GFCI breakers

– Bathroom circuits: 20A GFCI breakers

– Major appliances: 30-50A dedicated circuits (range, dryer, water heater)

– HVAC: 15-60A depending on system size

🎯 Pro Tip: When building or extensively renovating, install a panel with at least 30-40 circuit positions even if you don’t immediately need that many circuits. Adding circuits to spare positions costs far less than replacing an undersized panel later.

Detached garages, workshops, guest houses, and outbuildings typically receive power from the main house through an underground or overhead feeder, terminating at a subpanel in the detached structure.

Requirements:

– Feeder sized for subpanel rating and distance

– Separate grounding electrode system for detached buildings

– Neutral and ground buses must be separated (isolated)

– Minimum 60A rating typical for detached garages

– Weatherproof if installed in unconditioned space

Typical Configuration:

A 60-100A subpanel with 12-20 circuit positions:

– Garage door opener: 15A circuit

– Lighting: 15A circuit

– 120V receptacles: 20A circuits

– 240V equipment (welder, compressor, EV charger): 30-50A circuits

– Workshop equipment: dedicated 20-30A circuits

Commercial buildings use larger distribution boards as main panels and multiple smaller distribution boards or load centers as subpanels throughout the building.

Requirements:

– 3-phase service for buildings over certain size

– Higher short-circuit ratings (22kA minimum, 42-65kA common)

– Bolt-on breakers required in many jurisdictions

– Arc flash labeling per NFPA 70E

– Circuit directory with detailed load descriptions

Typical Configuration:

400-800A main distribution board with:

– Sub-feeder breakers: 100-200A to floor or area subpanels

– HVAC equipment: 20-100A circuits

– Elevator: dedicated 60-100A circuit

– Emergency lighting panels: 30-60A feeders

– Special equipment: dedicated circuits sized per load

Industrial facilities often use specialized distribution equipment called motor control centers (MCCs) that combine distribution, motor starters, and variable frequency drives in one integrated system.

Requirements:

– 480V 3-phase service common

– Very high short-circuit ratings (42-100kA)

– Integrated motor protection and control

– Arc flash protection systems

– Comprehensive labeling and safety signage

🎯 Pro Tip: Commercial and industrial installations require professional design by licensed electrical engineers. Distribution equipment selection involves complex calculations for voltage drop, fault current, coordination, and arc flash hazard analysis.

Solar photovoltaic systems connect to electrical distribution boxes through dedicated circuit breakers on special bus bars or via supply-side connections before the main breaker.

Requirements:

– Backfeed-rated breakers for solar connection

– 120% rule compliance (NEC 705.12(D)(2))

– Rapid shutdown controls near distribution box

– Appropriate labeling for multiple sources

– Ground fault protection for PV circuits

Typical Configuration:

– Inverter output breaker: 20-60A depending on system size

– Connection to main bus bar or load-side tap

– AC disconnect near distribution box

– Additional subpanel for PV system equipment if needed

Before selecting a distribution box, you need to determine the total electrical load it must serve. This calculation follows NEC Article 220 for residential applications or more detailed engineering calculations for commercial buildings.

Formula for simple residential subpanels:

Total Amperage = (Sum of Continuous Loads × 1.25) + Non-Continuous Loads

Example:

– Workshop continuous load (lighting running 3+ hours): 5A × 1.25 = 6.25A

– Non-continuous load (power tools): 45A

– Total calculated load: 6.25A + 45A = 51.25A

– Result: Select minimum 60A subpanel (next standard size up)

For main service panels, calculations become more complex with demand factors applied to different types of loads. Most jurisdictions require licensed electricians or engineers to perform these calculations.

Count how many individual circuits you need now and estimate future expansion needs. It’s far more cost-effective to install excess capacity during initial installation than to replace an undersized panel later.

| Application | Minimum Circuits | Recommended Circuits |

|---|---|---|

| Small Residential (800-1500 sq ft) | 20-24 | 30-32 |

| Medium Residential (1500-3000 sq ft) | 24-30 | 40-42 |

| Large Residential (>3000 sq ft) | 30-40 | 42-60 |

| Detached Garage/Workshop | 6-8 | 12-16 |

| Small Commercial | 20-30 | 40-50 |

🎯 Pro Tip: Plan for 20-30% spare circuit capacity. This allows for future additions like electric vehicle chargers, home offices, remodeling projects, or new appliances without panel replacement.

For residential applications under 200A, load centers provide the most economical solution. They feature plug-in breakers, compact design, and meet all code requirements for typical homes.

Choose a distribution board for:

– Commercial buildings

– Services over 200A

– Applications requiring bolt-on breakers

– Environments with high available fault current (>22kA)

– Industrial or harsh environments

The higher initial cost of distribution boards pays off in superior durability, safety, and flexibility for demanding applications.

The installation location determines required environmental protection ratings:

Indoor dry locations: Standard NEMA 1 enclosures work for most residential and commercial indoor applications.

Outdoor or damp locations: Require NEMA 3R (rainproof) minimum. These enclosures include features like drip shields and gaskets to prevent water intrusion.

Corrosive environments: Coastal areas, chemical plants, and industrial facilities may require NEMA 4X (stainless steel or fiberglass) enclosures resistant to corrosion.

Temperature extremes: Verify the panel’s temperature rating matches your environment. Standard panels rate for -10°C to +40°C, but specialized panels exist for extreme conditions.

NEC Article 408 establishes mandatory requirements for all panelboards (distribution boxes):

408.3(A) – Physical Protection: Panelboards must be enclosed to protect energized parts from physical damage and accidental contact.

408.4 – Circuit Directory: Every panelboard must include a circuit directory or identification of circuits on the face of the panel. This isn’t optional—it’s required for safety during maintenance and emergencies.

408.36 – Overcurrent Protection: Each panelboard must be protected by overcurrent devices (circuit breakers or fuses) with ratings not exceeding the panel’s rating.

408.37 – Back-Fed Devices: When using breakers in backfeed applications (like solar inverters), special backfeed-rated breakers with additional securing fasteners are required.

Ensure your selected distribution box carries appropriate UL listing (UL 67 for panelboards) and meets local jurisdiction requirements, which may exceed minimum NEC standards.

Problem: Installing a main breaker larger than the panel’s bus bar rating creates a serious safety hazard. The breaker won’t protect the bus bars from overcurrent damage, potentially causing overheating and fire.

Common scenarios:

– Replacing a 125A main breaker with 200A in a panel rated for 125A

– Attempting to increase service capacity without replacing the entire panel

– Misunderstanding that bus bar rating, not physical breaker space, determines maximum breaker size

Correction: The main breaker rating must never exceed the panel’s bus bar rating shown on the label. Increasing service capacity requires replacing the entire panel with one rated for the higher amperage.

⚠️ Warning: Panel bus bar ratings are permanently established by the manufacturer and cannot be field-modified. Attempting to exceed these ratings violates NEC 408.36 and creates fire hazards.

Problem: NEC 240.24(D) prohibits installing overcurrent protection devices in bathrooms, and 240.24(E) restricts installation in clothes closets or similar spaces where stored materials could prevent access.

Common scenarios:

– Hiding panels behind clothing in closets

– Installing panels in bathroom walls for convenient access

– Placing panels in storage rooms where boxes and materials accumulate

Correction: Distribution boxes must install in readily accessible locations with clear working space. NEC 110.26 requires minimum working clearances: 3 feet wide, 30 inches deep, and 6.5 feet high (or panel height, whichever is greater) in front of the panel.

Problem: Improperly bonding neutral and ground bars in subpanels creates dangerous parallel grounding paths. Unlike main panels where neutral and ground bond together, subpanels must keep these completely separate.

Common scenarios:

– Leaving factory bonding screw installed in subpanels

– Running 3-wire feeders (hot-hot-neutral) to subpanels without separate ground

– Connecting ground and neutral wires to the same bus bar in subpanels

Correction: In subpanels, remove the bonding screw between neutral and ground buses. Install separate neutral and ground bus bars. Run 4-wire feeders (2 hots, neutral, and ground) from main panel to subpanel. Connect the grounding conductor to the ground bus only, neutral to the isolated neutral bus.

⚠️ Warning: Improper grounding can energize equipment enclosures, creating shock hazards, and can cause ground fault protection devices to malfunction.

Problem: Blocking access to distribution boxes with furniture, storage, or building features violates working space requirements and creates safety hazards during maintenance and emergencies.

Common scenarios:

– Placing shelving units in front of panels

– Installing panels behind doors that don’t open to full clearance

– Allowing storage to accumulate in required working space

– Installing panels too high for safe access

Correction: Maintain NEC 110.26 working clearances at all times:

– Width: 30 inches wide or panel width (whichever is greater)

– Depth: 36 inches minimum for systems up to 600V

– Height: From floor to 6.5 feet high or to panel top (whichever is greater)

– Illumination: Provide proper lighting for the working space

– Headroom: Minimum 6.5 feet overhead clearance

Problem: Exceeding a panel’s maximum circuit rating by installing too many tandem (double-stuff) breakers overloads the bus bar connection points and can void panel listings.

Common scenarios:

– Filling every position with tandem breakers to get more circuits

– Exceeding the panel’s maximum circuit rating shown on the label

– Installing tandems in positions not designed for them

Correction: Check the panel label for maximum number of circuits and specifically approved tandem breaker positions. Many panels specify “maximum 40 circuits” even if physical space exists for more. Never exceed the manufacturer’s maximum circuit rating, and only install tandem breakers in positions explicitly approved by the manufacturer.

Problem: NEC 110.16 requires arc flash warning labels on electrical equipment likely to require examination, adjustment, servicing, or maintenance while energized. Missing labels endanger service personnel.

Common scenarios:

– Older panels installed before arc flash labeling requirements

– DIY installations without proper warning labels

– Commercial installations without proper arc flash hazard analysis

Correction: Install appropriate arc flash warning labels on all distribution boxes. For residential installations, generic warning labels suffice. Commercial and industrial installations require detailed arc flash hazard analysis per NFPA 70E, calculating incident energy levels and establishing appropriate PPE requirements.

These terms actually refer to the same equipment—”circuit breaker panel” is the common term most homeowners use, while “electrical distribution box” or “panelboard” are the more formal industry terms. All describe the metal enclosure containing circuit breakers that distribute power throughout your building.

The term “panelboard” appears in NEC Article 408, which governs these devices. It’s defined as “a single panel or group of panel units designed for assembly in the form of a single panel, including buses and automatic overcurrent devices.” Whether you call it a distribution box, panel, circuit breaker panel, breaker box, or load center, you’re talking about the same essential piece of electrical equipment that divides incoming power into branch circuits while providing overcurrent protection for each circuit.

Most modern homes require a 200-amp main service panel to meet current and future electrical needs. This capacity handles typical residential loads including heating and cooling systems, major appliances, electric vehicle charging, and standard lighting and receptacle circuits with room for future expansion.

Smaller homes under 1,500 square feet without electric heat or air conditioning might adequately function with 100-150 amp service, but 200 amps has become the standard for new construction since the 1980s. Larger homes exceeding 3,000 square feet, houses with extensive electric heating, multiple HVAC systems, or substantial workshop equipment may require 300-400 amp service panels. The calculation process specified in NEC Article 220 determines exact service requirements based on square footage, appliances, heating/cooling type, and specific loads, though licensed electricians typically perform these calculations to ensure accuracy and code compliance.

Installing or replacing electrical distribution boxes requires licensed electricians in most jurisdictions due to the critical safety implications and code complexity involved. While homeowners can legally perform their own electrical work in some areas, several practical and safety factors make professional installation strongly advisable.

Distribution box installation involves working with potentially lethal voltages at the service entrance. The utility company must disconnect service during installation, which requires coordination only electricians can typically arrange. Installation must comply with numerous NEC requirements covering working clearances, grounding, bonding, conductor sizing, and load calculations. Permits and inspections are mandatory for distribution box work, and inspectors expect professional-quality installations meeting all code requirements. Mistakes in distribution box installation can cause house fires, create shock hazards, or result in expensive correction work.

Insurance and liability concerns add additional complications—most homeowner insurance policies require licensed electrician installation for major electrical work. If you’re considering this as a DIY project, consult your local building department first, but expect them to require licensed electrician installation for panel work.

NEC Article 408 titled “Switchboards, Switchgear, and Panelboards” contains all code requirements specifically governing electrical distribution boxes (panelboards). This article establishes mandatory construction standards, installation requirements, and safety provisions that every distribution box installation must meet.

Key requirements from NEC 408 include: panelboards must be protected by overcurrent devices rated not greater than the panel rating (408.36); all panelboards require circuit directories identifying what each circuit controls (408.4); panelboards must install in cabinets or cutout boxes providing physical protection (408.3); and special provisions govern lighting and appliance branch-circuit panelboards which protect more than 10% of overcurrent devices rated 30A or less.

Understanding NEC 408 matters because it defines what makes a distribution box installation legal and safe. Inspectors use Article 408 as their checklist when evaluating panel installations. Insurance companies may deny claims for electrical fires if the distribution box violated NEC 408 requirements. When purchasing or installing distribution equipment, verifying compliance with Article 408 ensures you’re getting properly designed and approved equipment that will pass inspection and provide safe, code-compliant service.

Several clear indicators suggest your electrical distribution box has reached the end of its service life or no longer meets current needs. Physical signs like rust, corrosion, burning smells, or scorch marks inside the panel indicate serious problems requiring immediate professional evaluation and likely replacement.

Frequent breaker tripping without obvious overloads suggests the panel can’t handle your electrical demands or breakers have degraded with age. Running out of circuit positions when you need to add loads means the panel has insufficient capacity for your current needs. Some older panel types—including Federal Pacific Electric (FPE) panels and certain Zinsco panels—have documented safety issues and should be replaced regardless of apparent condition.

Functional obsolescence occurs when panels lack required modern protection like GFCI and AFCI circuits mandated by current codes, or when upgrading to electric vehicle charging, solar systems, or major appliances requires more capacity than your current panel provides. Age alone isn’t necessarily disqualifying—properly maintained panels can last 40-60 years—but panels over 25 years old benefit from professional inspection. If your panel shows any of these warning signs, schedule evaluation by a licensed electrician who can assess whether repair, partial upgrade, or complete replacement best addresses your situation.

Main breaker panels include a large main circuit breaker—typically at the top of the panel—that can disconnect all power to the panel with a single switch. This main breaker serves as the overcurrent protection for the entire panel and provides a convenient shut-off point for the whole electrical system. Main breaker panels are required for main service panels where the utility service connects.

Main lug only (MLO) panels lack this main breaker, instead featuring only lug connections for incoming power conductors. MLO panels receive their overcurrent protection from a breaker located upstream in the electrical system—typically from a breaker in the main panel feeding the MLO panel. These panels work perfectly for subpanel applications where the feeder breaker in the main panel provides overcurrent protection.

The choice between main breaker and MLO depends on application: use main breaker panels for main service installations where they’re required by code, and where you want a single disconnect for the entire electrical system. Choose MLO panels for subpanel applications where they’re protected by upstream breakers, and where they typically cost less than equivalent main breaker panels. Some installers prefer MLO subpanels because they don’t “waste” two circuit positions on the main breaker, providing more circuit capacity in the same size cabinet—though this minor advantage rarely outweighs other selection criteria.

Solar photovoltaic systems do connect to electrical distribution boxes, but the connection must follow specific NEC Article 705 requirements for interconnected power systems. The solar inverter output connects through a dedicated circuit breaker that back-feeds power into your distribution box, but this isn’t as simple as just adding another breaker.

The 120% rule (NEC 705.12(D)(2)) governs most solar connections to distribution boxes. This rule states that the sum of the main breaker and the solar breaker ratings cannot exceed 120% of the panel’s bus bar rating. For example, a panel with a 200A bus bar and 200A main breaker can add a maximum 40A solar breaker (200A main + 40A solar = 240A, which equals 120% of 200A bus). The solar breaker must install at the opposite end of the bus bar from the main breaker to distribute current loading.

Additional requirements include: using special breaker types rated for backfeed applications with additional securing fasteners preventing the breaker from coming loose; installing rapid shutdown controls near the distribution box as required by NEC 690.12; proper labeling indicating multiple power sources; and ensuring the solar system includes ground fault protection. Many installations benefit from dedicated subpanels for solar equipment, separating solar circuits from regular building loads and providing clearer organization. Always work with licensed electricians experienced in solar installations, as improper connections create serious safety hazards and can void equipment warranties.

Understanding electrical distribution boxes transforms these commonplace metal cabinets from mysterious boxes into comprehensible, critical components of every building’s electrical infrastructure. These devices serve as the heart of your electrical system, safely dividing incoming power into manageable circuits while providing essential overcurrent protection.

Key Takeaways:

1. Electrical distribution boxes distribute incoming electrical power to branch circuits throughout buildings while protecting each circuit with individual overcurrent protection devices (circuit breakers).

2. Main panels contain main disconnects and serve as the primary service entrance point, while subpanels extend distribution capacity and must maintain separated neutral and ground buses.

3. Residential load centers with plug-in breakers suit most homes under 200A, while commercial distribution boards with bolt-on breakers serve larger or more demanding applications.

4. NEC Article 408 establishes mandatory requirements for panelboard installation including proper working clearances, circuit directories, overcurrent protection, and environmental enclosures.

5. Common mistakes like oversized main breakers, improper grounding in subpanels, and inadequate working clearances create serious safety hazards and code violations requiring professional correction.

Proper selection, installation, and maintenance of electrical distribution boxes ensures safe, reliable electrical service for decades. When in doubt about your distribution box’s condition, capacity, or code compliance, professional evaluation provides peace of mind and prevents costly problems.

Related Resources:

– Waterproof Distribution Box: Complete Protection Guide for Outdoor Applications

– DC Circuit Breaker: Essential Protection for Solar and Battery Systems

– DC Fuse Selection: Sizing and Application Guide for PV Systems

Ready to upgrade or install a new electrical distribution box? Our technical team can help you select the right panel type, calculate proper sizing, and ensure NEC 408 compliance for your specific application. Contact SYNODE for professional guidance on distribution box selection and installation planning.

Last Updated: October 2025

Author: SYNODE Technical Team

Reviewed by: Electrical Engineering Department