Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

A 12 volt DC circuit breaker protects low-voltage electrical systems from overcurrent conditions that could damage equipment or create fire hazards. From marine vessels and RVs to off-grid solar systems and automotive applications, understanding how to properly select and install 12V breakers ensures safe, reliable operation of your DC electrical system.

This comprehensive guide covers everything professional installers and DIY enthusiasts need to know about 12 volt DC circuit breakers, including sizing calculations, application-specific requirements, and common installation mistakes to avoid.

Twelve volt systems present unique challenges that require specialized protection devices. Unlike higher-voltage solar applications where DC circuit breakers handle 600V or 1000V, 12V breakers must interrupt much higher currents at lower voltages.

Key operational differences:

The arc suppression challenge becomes more complex at low voltages. When a breaker interrupts current, an electrical arc forms between the contacts. At 12V, this arc is easier to maintain than at higher voltages, requiring more robust arc chutes and contact designs.

Current levels run significantly higher in 12V systems compared to equivalent power systems at higher voltages. A 1200W load draws 100A at 12V but only 5A at 240V. This demands heavier conductors, larger terminals, and breakers rated for sustained high current flow.

💡 Key Insight: According to NEC Article 690.8, circuit breakers must be rated for continuous operation at 125% of maximum current. For 12V solar systems, this multiplier becomes critical due to already-high current levels.

Marine environments demand the most from 12V protection devices. Salt air, moisture, vibration, and constant movement create challenging operating conditions.

Typical marine circuits:

Marine-rated breakers require ignition-protected enclosures per ABYC E-11 standards. These prevent sparks from igniting fuel vapors in engine compartments and fuel storage areas.

Recreational vehicles typically run dual electrical systems: 120V AC shore power and 12V DC house systems. The 12V side powers:

Essential 12V loads:

RVIA standards require main breaker panels with individual circuit protection. Modern RVs use thermal-magnetic solar circuit protection devices rated for mobile applications with vibration resistance.

Small-scale solar installations frequently operate at 12V nominal voltage. These systems require protection at multiple points:

Solar charge controller input: Protects controller from array short circuits

Battery connection: Main breaker between battery bank and busbar

Individual loads: Separate breakers for each major appliance

Inverter connection: High-current breaker for DC-to-AC conversion

Battery systems present unique challenges. During bulk charging, currents can reach 50-100A or more. Lead-acid batteries can deliver thousands of amps during short-circuit conditions, making proper DC overcurrent protection absolutely critical.

⚠️ Important: Battery short-circuit currents can exceed 10,000A in large battery banks. Breakers must have sufficient interrupting capacity (AIC rating) to safely clear these faults without exploding or welding shut.

Modern vehicles increasingly use add-on accessories requiring individual circuit protection:

Automotive applications require breakers with reset mechanisms accessible to vehicle operators. Push-button or rocker-style reset breakers work well in these environments.

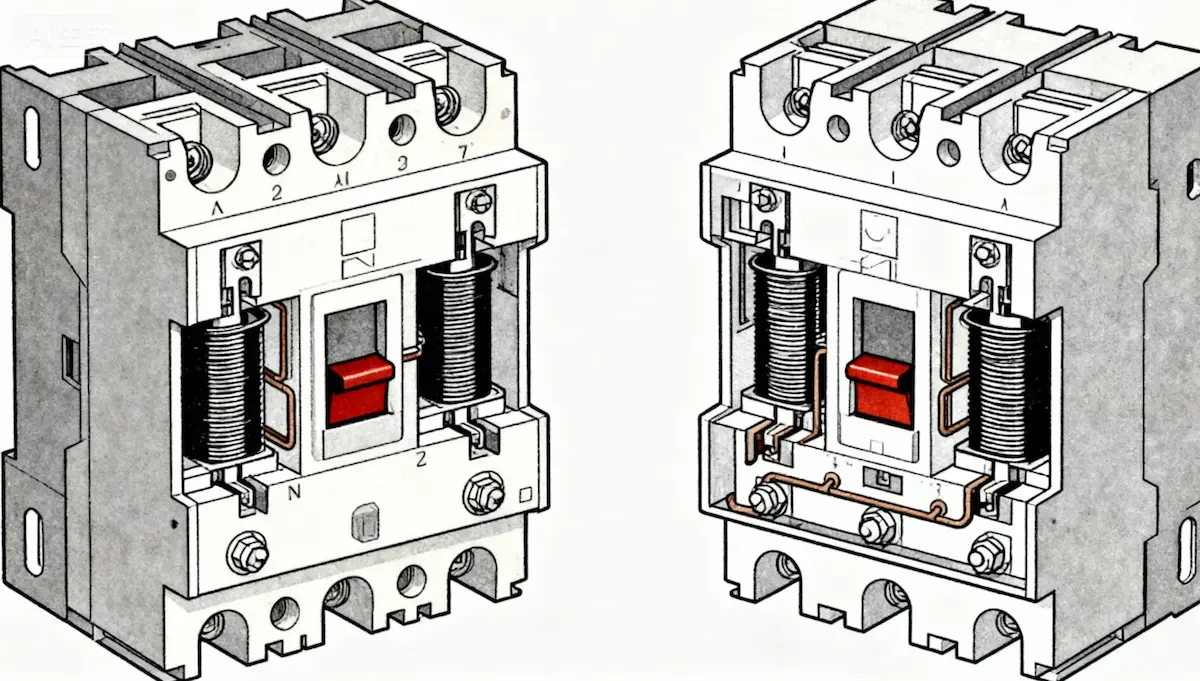

These combination devices use two independent trip mechanisms for comprehensive protection:

Thermal element: Bimetallic strip heats and bends under sustained overcurrent, tripping the breaker after a time delay proportional to current level. This protects against moderate overloads (125-200% of rating).

Magnetic element: Electromagnetic coil creates magnetic field proportional to current. At high fault currents (typically 5-10x rating), the magnetic force instantly trips the breaker, providing short-circuit protection.

Thermal-magnetic breakers offer the best overall protection for most applications. They’re available from 5A to 400A ratings with various mounting styles.

These specialized breakers use hydraulic damping for precise time-current characteristics:

A magnetic core moves through viscous fluid when current flows. At normal currents, the fluid restricts movement and the breaker stays closed. During overload conditions, magnetic force overcomes the fluid resistance and trips the mechanism.

Advantages over thermal-magnetic:

Hydraulic-magnetic breakers cost 2-3x more than thermal-magnetic but excel in demanding applications like battery management systems and critical equipment protection.

Surface-mount thermal breakers provide the simplest overcurrent protection:

A bimetallic disc snaps from convex to concave when heated by overcurrent, physically breaking the circuit. The user must press a reset button to restore the circuit after the breaker cools.

Common applications:

These breakers typically cost $3-15 each and install with two mounting screws. They’re available in ratings from 3A to 50A.

These breakers use the same form factor as standard automotive fuses but provide resettable protection:

The breaker fits standard fuse holders and panels designed for ATO/ATC blade fuses. A press-button on top allows manual reset after trip. Some models include a trip indicator (red button pops out) for easy fault identification.

Blade breakers work well in vehicles and systems already using blade fuse panels. They cost $8-20 each depending on current rating.

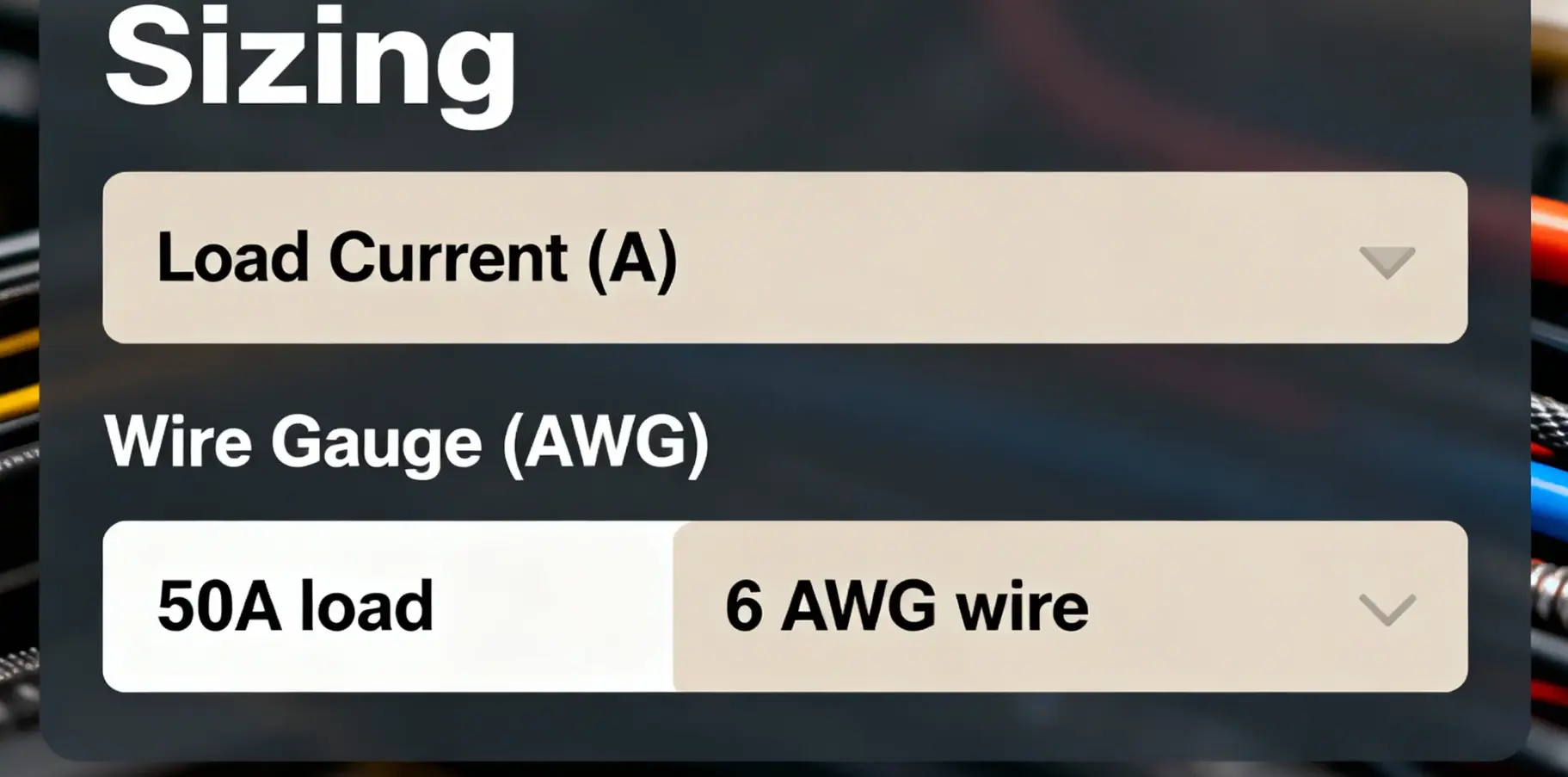

NEC 690.8(B)(1) requires sizing conductors and overcurrent devices at 125% of maximum current for continuous loads (3+ hours). Solar charging qualifies as continuous operation.

Calculation example:

This multiplier accounts for conductor heating during extended operation and ensures the breaker won’t nuisance trip during normal charging cycles.

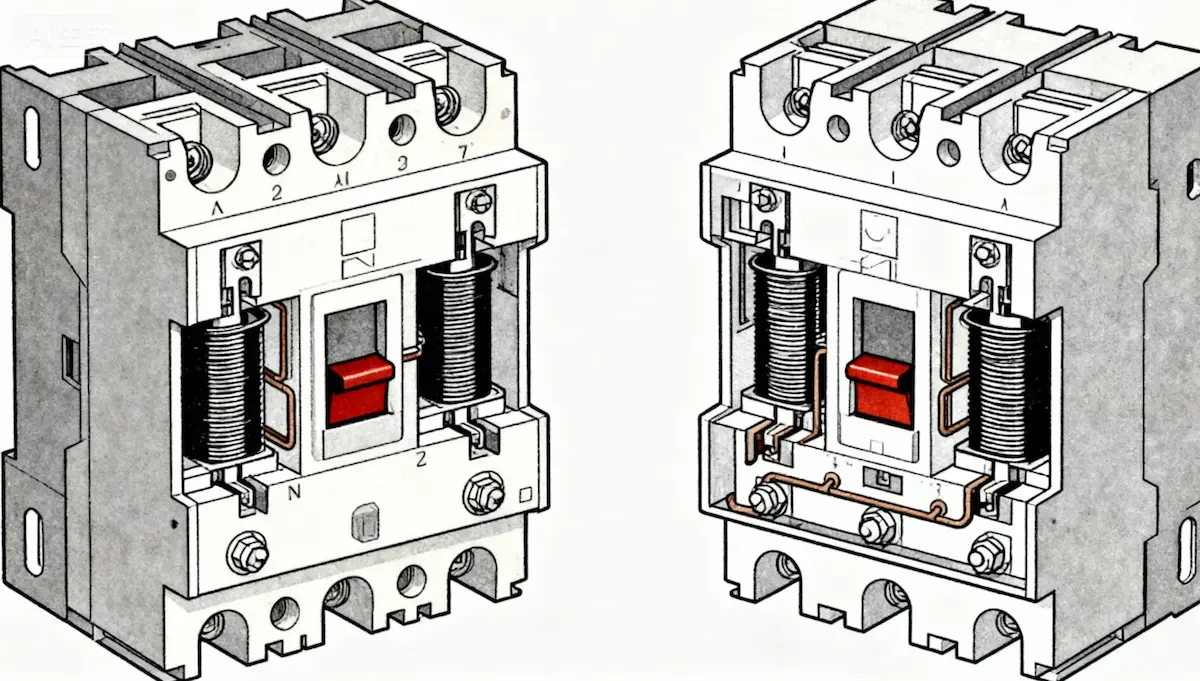

Circuit breakers must protect the conductor, not just the load. The breaker rating cannot exceed the wire’s ampacity per NEC Table 310.16.

Common 12V wire sizes and ampacities (75°C rating):

| Wire Gauge (AWG) | Ampacity (75°C) | Max Breaker Rating | Typical Use |

|---|---|---|---|

| 14 AWG | 20A | 15A | Lighting, small loads |

| 12 AWG | 25A | 20A | General circuits |

| 10 AWG | 35A | 30A | Water pumps, motors |

| 8 AWG | 50A | 40A | Inverters, chargers |

| 6 AWG | 65A | 60A | Battery mains |

| 4 AWG | 85A | 80A | Large inverters |

| 2 AWG | 115A | 100A | High-power systems |

| 1/0 AWG | 150A | 150A | Main battery cables |

Ambient temperature affects breaker performance. Most breakers are rated at 25°C (77°F). Higher temperatures reduce current capacity:

Temperature derating factors:

In engine compartments or enclosed battery boxes where temperatures exceed 40°C, upsize the breaker to compensate. A 50A breaker at 50°C only provides reliable 41A protection (50A × 0.82 = 41A).

🎯 Pro Tip: In hot climates or enclosed spaces, install the breaker outside the high-temperature zone when possible. Running a short conductor from the battery to an externally-mounted breaker avoids derating and improves reliability.

At 12V, voltage drop becomes critical. A 0.5V drop represents 4% loss at 12V but only 0.2% at 240V. Keep circuits short and use adequately-sized conductors.

Voltage drop calculation: VD = (2 × L × R × I) / 1000

Where:

For critical loads, limit voltage drop to 3% maximum (0.36V at 12V). Non-critical loads can tolerate 5% drop (0.6V).

Loose connections cause heating, voltage drop, and potential fire hazards. Follow these torque specifications:

Standard terminal torques:

Use a calibrated torque screwdriver or torque wrench. Over-tightening damages terminals and conductors. Under-tightening allows arcing and overheating.

Ring terminals: Preferred for permanent installations. Crimp with proper tools and verify mechanical strength by tugging the terminal after crimping.

Fork terminals: Acceptable for low-vibration applications but can work loose. Not recommended for marine or vehicle use.

Bare wire under screw: Only acceptable for temporary or test connections. Use ring terminals for permanent installations.

Most thermal-magnetic breakers operate in any position, but check manufacturer specifications. Hydraulic-magnetic breakers often require vertical mounting with the trip mechanism facing up for proper fluid operation.

In mobile applications (RVs, boats, vehicles), ensure breakers tolerate expected orientations. Some breakers nuisance trip when mounted upside-down due to bimetallic strip orientation.

Moisture protection: Use NEMA 3R (rainproof) or NEMA 4X (waterproof) enclosures for outdoor installations. Individual breaker covers prevent moisture entry in open panels.

Vibration isolation: In vehicles and marine applications, mount breaker panels on vibration-isolating mounts or use breakers specifically rated for vibration service.

Corrosion prevention: Apply dielectric grease to terminals in corrosive environments. Tin-plated copper conductors resist corrosion better than bare copper.

❌ Using breaker as on/off switch: Breakers are protection devices, not switches. Frequent manual switching wears the mechanism and reduces reliability. Install a separate switch for routine on/off operation.

❌ Mixing breaker and conductor sizes: Installing a 30A breaker on 14 AWG wire (rated 15A max) creates a fire hazard. The breaker must protect the smallest conductor in the circuit.

❌ Installing breaker after the load: Breakers must be installed as close as possible to the power source (battery). Installing the breaker at the load end leaves the cable unprotected from source to load.

❌ Ignoring ambient temperature: Using standard-rated breakers in 50°C+ environments without derating leads to nuisance tripping or, worse, failure to trip during overload.

❌ Daisy-chaining multiple loads: Connecting several high-current loads to one breaker through a single junction point concentrates current and creates hot spots. Use separate circuits for major loads.

❌ Using AC-rated breakers: Standard AC circuit breakers cannot safely interrupt DC current. Always use breakers rated for DC voltage and current. UL 489 certification specifically addresses DC ratings.

Monthly: Manually trip and reset each breaker to prevent mechanism corrosion and sticking. This exercise is especially important for marine and outdoor applications.

Annually: Perform load testing by intentionally creating an overload condition (safely) to verify the breaker trips at rated current. Use a calibrated ammeter to measure trip current.

After any trip event: Investigate the cause before resetting. Repeated trips indicate an underlying problem that requires correction, not just continued reset attempts.

Replace breakers exhibiting these warning signs:

Breakers are relatively inexpensive compared to fire damage or equipment destruction. When in doubt, replace rather than risk continued use of a questionable breaker.

Quality 12V DC breakers typically provide:

Document installation dates and track trip events to establish replacement schedules for critical applications.

Verify breakers meet appropriate standards for your application:

UL 489: Molded-Case Circuit Breakers

IEC 60947-2: Low-Voltage Switchgear and Controlgear

ABYC E-11: Marine AC and DC Electrical Systems

SAE J1171: Automotive Circuit Breakers

Products listing these certifications have undergone rigorous testing for safety and performance.

The AIC (Ampere Interrupting Capacity) rating indicates the maximum fault current the breaker can safely interrupt. For 12V battery systems, specify breakers with:

Undersized AIC ratings lead to breaker explosion during high-fault events. This specification is non-negotiable for safety.

Silver-tungsten contacts: Provide superior arc resistance and longer service life. Standard in quality breakers.

Brass or copper contacts: Lower cost but wear faster. Acceptable for low-duty applications only.

Double-break design: Interrupts current at two points simultaneously, improving arc extinction. Preferred for currents above 50A.

Professional-grade manufacturers include:

Budget brands may save money initially but often fail prematurely in demanding applications. For critical systems, invest in quality breakers from established manufacturers.

Can I use a 12V DC breaker on a 24V system?

No. Breakers must be rated for the system voltage or higher. A 12V-rated breaker cannot safely interrupt arcs at 24V. Use breakers rated for 32V or higher for 24V systems. Voltage rating is a maximum specification that cannot be exceeded.

Why does my breaker keep tripping on cold mornings?

Cold temperatures temporarily increase battery internal resistance, causing voltage to drop under load. The breaker interprets the resulting current spike as an overload. This indicates borderline breaker sizing. Upsize by one rating increment to eliminate nuisance tripping.

What’s the difference between a circuit breaker and a fuse for 12V systems?

Circuit breakers provide resettable protection and can be used as occasional switches, while fuses require replacement after every fault. Breakers cost more initially ($15-50 vs $1-5 for fuses) but save money long-term in frequently-serviced systems. Fuses offer faster response to short circuits and have no moving parts to fail.

How close to the battery must the main breaker be installed?

NEC 690.8 requires overcurrent protection within 10 feet of the power source. For batteries, install the main breaker within 7 inches when possible, using properly-sized cable for this short run. This minimizes unprotected conductor length that could short-circuit.

Do thermal-magnetic breakers work at extremely cold temperatures?

Most breakers function down to -20°C (-4°F), but response time slows as the bimetallic strip stiffens. For arctic or high-altitude applications, specify breakers rated to -40°C or use hydraulic-magnetic types that aren’t temperature-dependent. Check manufacturer specifications for exact low-temperature ratings.

Can I parallel two breakers to handle higher current?

Never parallel breakers. They won’t share current equally due to manufacturing tolerances and contact resistance differences. One breaker carries most of the load and trips first, leaving the circuit unprotected. Use a single breaker rated for total circuit current.

What causes a breaker to trip immediately after resetting?

Immediate tripping indicates a hard short-circuit or major overcurrent condition. Common causes include damaged cable insulation, pinched wires, failed equipment, or reversed polarity connections. Disconnect all loads, test the circuit with a multimeter, and trace the fault before re-energizing the circuit.

Selecting and installing 12 volt DC circuit breakers correctly ensures reliable overcurrent protection for low-voltage electrical systems. The key considerations include proper sizing at 125% of maximum current for continuous loads, matching breaker ratings to conductor ampacity, accounting for temperature derating in hot environments, and using breakers certified for DC interruption.

Quality breakers from established manufacturers provide the reliability critical systems demand. While budget options exist, the relatively small cost difference compared to potential fire damage makes professional-grade breakers the smart choice for permanent installations.

Whether you’re protecting a marine electrical system, RV house circuits, off-grid solar battery bank, or automotive accessories, following the guidelines in this article ensures code-compliant, safe operation for years to come.