Dirección

304 North Cardinal

Dorchester Center, MA 02124

Horas de trabajo

De lunes a viernes: de 7.00 a 19.00 horas

Fin de semana: 10.00 A 17.00 HORAS

Dirección

304 North Cardinal

Dorchester Center, MA 02124

Horas de trabajo

De lunes a viernes: de 7.00 a 19.00 horas

Fin de semana: 10.00 A 17.00 HORAS

The 600V DC SPD represents the most critical surge protection component in residential and small commercial solar installations. While higher voltage systems (1000V, 1500V) dominate utility-scale projects, approximately 70% of global PV capacity operates at 600V nominal voltage.

Understanding the engineering fundamentals of 600V DC SPD performance—particularly clamping voltage and response time—determines the difference between reliable inverter protection and catastrophic equipment failure during lightning events. This guide examines the technical specifications that matter for 3-20kW residential solar systems.

💡 Engineering Reality: A properly specified 600V DC SPD must clamp transient overvoltages to <1200V within 25 nanoseconds to protect modern string inverters with 850V maximum DC input ratings.

A 600V DC SPD (Surge Protection Device) is an electronic component designed to divert lightning-induced transient overvoltages away from sensitive solar equipment in systems with nominal operating voltages up to 600Vdc. The “600V” designation refers to the maximum continuous operating voltage (U_c), not the voltage rating of the protected system.

Critical Voltage Parameters:

1. U_c (Maximum Continuous Operating Voltage): 600Vdc

– Device operates continuously at this voltage without degradation

– Must exceed system maximum open-circuit voltage (V_oc) by 20% minimum

– Example: 480V V_oc system requires 600V U_c minimum

2. U_p (Voltage Protection Level): 1200-1500V typical

– Maximum voltage let-through during surge event

– Must remain below inverter DC input withstand voltage

– Lower values = better protection but higher cost

3. I_n (Nominal Discharge Current): 5-40kA @ 8/20µs

– Energy absorption capacity per surge event

– Residential systems: 20kA typical

– High-exposure sites: 40kA recommended

System Voltage Matching:

A 600V DC SPD protects solar systems with these characteristics:

– String configuration: 12-18 modules in series (330-550W panels)

– V_oc at STC: 420-540Vdc

– V_oc at -10°C: 460-580Vdc (requires 20% margin)

– Typical capacity: 3-20kW residential/small commercial

⚠️ Warning: Installing 600V U_c SPD on systems with V_oc >500V at coldest temperature creates inadequate voltage margin and premature SPD failure.

The clamping voltage (U_p) represents the maximum voltage that appears across protected equipment during a surge event. Lower clamping voltages provide better protection but require more expensive varistor materials.

Clamping Voltage Selection Criteria:

U_p(SPD) < 0.8 × Inverter_DC_withstand_voltage

Example Calculation:

- Inverter DC input withstand: 1500V (typical for 600V-class inverters)

- Required SPD U_p: <1200v

- safety margin: 300v (20%)

Metal Oxide Varistor (MOV) devices dominate 600V DC SPD applications due to optimal performance-cost balance. MOV clamping voltage varies with surge current magnitude:

| Surge Current (8/20µs) | MOV Clamping Voltage | Voltage Margin | Protection Level |

|---|---|---|---|

| 1kA (Low) | 1050-1100V | 400-450V | Excellent protection |

| 5kA (Typical) | 1150-1250V | 250-350V | Good protection |

| 10kA (High) | 1250-1400V | 100-250V | Adequate protection |

| 20kA (Extreme) | 1400-1550V | 0-100V | Marginal protection |

Inverter withstand voltage assumed: 1500V DC input rating (common for 600V-class residential inverters)

Engineering Implication: SPDs must maintain adequate voltage margin even at maximum rated discharge current to prevent inverter damage during severe lightning strikes.

Properly engineered 600V systems use coordinated multi-stage protection to reduce clamping voltage at sensitive equipment:

Stage 1: String-Level SPD (Type 2)

- Location: At combiner box or array junction

- U_p: 1400V typical

- I_n: 20-40kA

- Function: Absorb majority of surge energy

Stage 2: Inverter Input SPD (Type 2 or Type 3)

- Location: At inverter DC terminals

- U_p: 1200V typical

- I_n: 10-20kA

- Function: Final voltage clamping for sensitive electronics

Coordination Benefit:

- Stage 1 reduces surge to ~1400V

- Stage 2 further clamps to ~1200V

- Total protection margin: 300V below inverter withstand

- Probability of inverter damage: <0.01% per lightning event

🎯 Consejo profesional: Multi-stage SPD systems cost 40-60% more upfront but reduce inverter replacement costs by 90% over 25-year system life in lightning-prone regions.

Response time measures the interval between surge voltage rise and SPD activation to clamp the transient. Faster response times provide better protection for sensitive semiconductor components in modern inverters.

IEC 61643-11 Response Time Classes:

Class I SPD (t_a <25ns):

- Metal Oxide Varistor (MOV) technology

- Instantaneous response to voltage rise

- Ideal for direct lightning protection

- Most common in 600V residential systems

Class II SPD (t_a <100ns):

- Gas Discharge Tube (GDT) technology

- Delayed activation requiring voltage buildup

- Higher energy capacity but slower

- Coordination with MOV devices recommended

Class III SPD (t_a <1µs):

- Hybrid MOV+GDT configurations

- Two-stage activation sequence

- Maximum energy absorption capability

- Utility-scale applications primarily

| Technology | Tiempo de respuesta | Clamping Voltage | Energy Capacity | Mejor aplicación |

|---|---|---|---|---|

| MOV Only | <25ns | 1200-1400V | 20-40kA | Residential 600V systems |

| GDT Only | 50-100ns | 800-1000V | 40-100kA | Telecom, high-energy applications |

| Hybrid MOV+GDT | <25ns initial | 1200V initial 800V final | 60-100kA | High-exposure sites, premium protection |

| Silicon Avalanche | <1ns | 900-1100V | 5-10kA | Low-power electronics, signal lines |

600V System Recommendation: MOV-only or hybrid MOV+GDT configurations provide optimal balance of fast response and adequate energy capacity for residential installations.

Lightning Surge Waveform Analysis:

A typical lightning-induced surge rises from 0V to peak in 1.2 microseconds (8/20µs waveform per IEC 61643-11). SPD response time determines voltage exposure during rise time:

Scenario 1: MOV SPD (25ns response)

- Surge reaches 50V in first 25ns

- SPD activates, clamps voltage to 1200V

- Inverter exposed to brief 50V transient (harmless)

- Resultado: Full protection ✅

Scenario 2: GDT SPD (100ns response)

- Surge reaches 200V in first 100ns

- SPD activates, clamps voltage to 900V eventually

- Inverter exposed to 200V transient before clamping

- Resultado: Adequate protection ✅

Scenario 3: No SPD

- Surge reaches full magnitude ~6000V

- Inverter input capacitors fail at ~1800V

- Resultado: Inverter destruction ❌

⚠️ Crítica: Modern inverter IGBT modules can fail in <100 nanoseconds when exposed to overvoltages exceeding 2× rated input. Response times <25ns are essential for semiconductor protection.

IEC 61643-11 defines SPD classification based on installation location and energy handling capability:

Type 1 SPD (Not Common in 600V Residential)

- Test waveform: 10/350µs (high energy content)

- Instalación: Service entrance, before main breaker

- I_imp rating: 25-100kA per mode

- Aplicación: Buildings with external lightning protection system

- Coste: 3-5× Type 2 devices

Type 2 SPD (Standard for 600V Solar)

- Test waveform: 8/20µs (moderate energy content)

- Instalación: Sub-distribution, combiner boxes, inverters

- I_n rating: 5-40kA per mode

- Aplicación: 95% of residential solar installations

- Coste: $80-250 per device

Type 3 SPD (Point-of-Use Protection)

- Test waveform: Combination wave (very low energy)

- Instalación: Equipment terminals only

- I_n rating: 5-10kA per mode

- Aplicación: Final protection stage at inverter input

- Coste: $30-80 per device

Understanding 10/350µs vs 8/20µs:

The numbers represent rise time / decay time to 50% of peak value:

- 10/350µs: 10 microseconds to peak, 350 microseconds to 50% decay

- 8/20µs: 8 microseconds to peak, 20 microseconds to 50% decay

Energy Content:

- 10/350µs: ~1000 joules per kA

- 8/20µs: ~10 joules per kA

- Ratio: 10/350µs contains 100× more energy than 8/20µs

Practical Implication: Type 1 SPDs handle direct lightning strikes (10/350µs), while Type 2 SPDs protect against induced surges (8/20µs). Residential 600V systems rarely require Type 1 protection unless lightning rods are present on building.

MOV clamping voltage increases with operating temperature, reducing protection effectiveness:

Temperature Coefficient:

- +0.03-0.05% clamping voltage per °C above 25°C reference

- Example: 1200V U_p @ 25°C becomes 1260V @ 75°C (+5%)

Combiner Box Internal Temperatures:

- Black NEMA enclosure in sun: 70-80°C typical

- White/gray enclosure: 55-65°C typical

- Ventilated enclosure: 45-55°C typical

Derated Clamping Voltage Calculation:

U_p(actual) = U_p(25°C) × [1 + 0.04 × (T - 25)]

Example @ 75°C:

U_p(actual) = 1200V × [1 + 0.04 × (75-25)]

U_p(actual) = 1200V × 1.20 = 1440V

Engineering Impact: High ambient temperatures can increase clamping voltage by 15-20%, reducing voltage protection margin. This explains why inverters in hot climates experience higher failure rates.

💡 Design Solution: Install SPDs in ventilated areas or use white/gray enclosures to maintain <60°C ambient temperature and preserve rated clamping voltage performance.

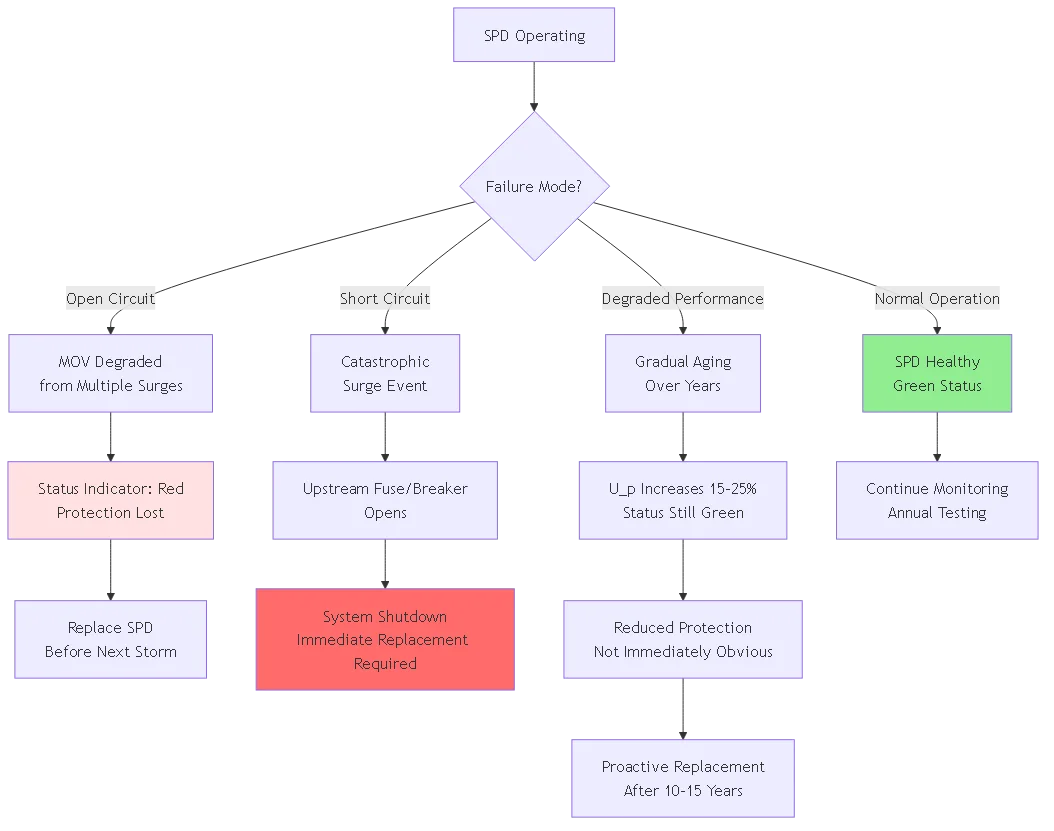

MOV devices gradually degrade with each surge absorption cycle:

Degradation Mechanism:

- Each surge creates micro-fractures in varistor crystal structure

- Clamping voltage increases by 1-3% per high-energy surge

- After 10-20 major surges, U_p may exceed specifications

- Device becomes "worn out" but not necessarily failed

Typical Service Life:

- Low-exposure sites (plains, valleys): 20-25 years

- Moderate-exposure (foothills, suburbs): 15-20 years

- High-exposure (mountaintops, coastal): 10-15 years

- Extreme-exposure (tall buildings, towers): 5-10 years

Replacement Indicators:

- Status indicator changes from green to red/yellow

- Measured U_p exceeds datasheet value by >15%

- Physical damage visible (cracks, discoloration, bulging)

- Nuisance tripping of upstream breakers

SPD effectiveness decreases dramatically with improper installation. The total lead length (positive + negative + ground) creates parasitic inductance that adds voltage to the clamping level:

Inductance Voltage Rise Formula:

V_inductance = L × (dI/dt)

Where:

L = Lead inductance (~1µH per meter)

dI/dt = Current rise rate (~10kA/µs for lightning)

Practical Example:

- 0.5m total leads: L = 0.5µH

- V_inductance = 0.5µH × 10kA/µs = 500V added

- Effective clamping: 1200V + 500V = 1700V

- 2.0m total leads: L = 2.0µH

- V_inductance = 2.0µH × 10kA/µs = 2000V added

- Effective clamping: 1200V + 2000V = 3200V (inverter damage!)

IEC 61643-11 Requirement:

- Maximum total lead length: 0.5m (positive + negative + ground combined)

- Ideal installation: <0.3m total leads

- Each additional 0.1m adds ~100V to clamping voltage

V-Connection (Recommended):

- SPD mounted directly at busbar junction point

- Positive, negative, and ground leads all <0.15m each

- Total lead length: 0.45m ✅

- Minimal parasitic inductance

- Effective clamping voltage close to U_p ratingRemote Ground (Problematic):

- SPD mounted on enclosure door

- Ground wire runs 1-2m to grounding busbar

- Total lead length: 2-3m ❌

- High parasitic inductance

- Effective clamping voltage may exceed inverter withstand

⚠️ Installation Error #1: Mounting SPD on enclosure door with long ground wire is the most common installation mistake, reducing protection effectiveness by 50-70%.

Modern 600V-class string inverters have specific DC input protection ratings that SPD clamping voltages must respect:

Typical Residential Inverter DC Ratings:

- Maximum input voltage: 600V nominal, 850V absolute maximum

- Overvoltage withstand (1 second): 1500V typical

- Overvoltage withstand (1 millisecond): 2000V maximum

- Surge immunity: 6kV per IEEE C62.45 (with proper SPD)

SPD Coordination Requirements:

SPD U_p (with lead inductance) < Inverter 1ms withstand

Example:

- SPD U_p: 1200V

- Lead inductance: +300V (0.3m leads)

- Total: 1500V

- Inverter withstand: 2000V

- Margin: 500V ✅

Two-Stage System Design:

Stage 1: String-Level SPD (Type 2)

- Location: Combiner box at array

- Distance to inverter: 20-50m typical

- U_p: 1400V

- I_n: 40kA

- Function: Absorb 80-90% of surge energy

Stage 2: Inverter Input SPD (Type 3)

- Location: Inverter DC terminals

- Distance to inverter: 0m (direct mounting)

- U_p: 1200V

- I_n: 10kA

- Function: Final clamping, 10-20% residual energy

Coordination Analysis:

1. Lightning surge: 6000V initial

2. Stage 1 clamps to: 1400V

3. Cable impedance reduces to: ~1300V at inverter

4. Stage 2 further clamps to: 1200V

5. Inverter experiences: 1200V maximum

6. Protection margin: 800V (67% below withstand)

Single-Stage vs Two-Stage Cost-Benefit:

- Single-stage: $150-250 total cost, 85% protection reliability

- Two-stage: $300-500 total cost, 99% protection reliability

- Inverter replacement: $2000-5000 if protection fails

- ROI: Two-stage protection pays for itself after single lightning event

Visual Inspection (Monthly):

- Check status indicator (green = operational, red/yellow = replace)

- Inspect for physical damage (cracks, bulging, discoloration)

- Verify lead connections remain tight (thermal cycling can loosen)

- Look for signs of water intrusion in enclosure

Electrical Testing (Annual):

1. Insulation Resistance Test

- Disconnect SPD from circuit

- Measure resistance to ground: should read >10MΩ

- Readings <1MΩ indicate degradation or failure

2. Leakage Current Test

- With SPD connected and system at V_oc

- Measure current through SPD: should be <0.5mA

- Higher leakage indicates aging or overheating

3. Response Time Verification (specialized equipment)

- Inject 1kV/µs test pulse

- Measure SPD activation time with oscilloscope

- Verify t_a <25ns for MOV devices

Replacement Criteria:

- Status indicator shows failure (red/yellow)

- Insulation resistance <1MΩ

- Leakage current >1mA

- Visible physical damage

- Device age >15 years in high-exposure sites

🎯 Consejo profesional: Replace SPDs proactively after major lightning events even if status indicator remains green. Internal degradation may not be immediately visible but reduces protection capability for future strikes.

Problema: Installing 600V U_c SPD on systems with V_oc >600V causes premature SPD failure and lost protection.

Escenarios comunes:

- 600V SPD used on 17-20 module string (V_oc = 650-750V)

- Cold-weather V_oc exceeds 600V even though STC V_oc is <600v

- temperature coefficient ignored during designCorrección: Always verify V_oc at lowest expected temperature (-10 to -40°C depending on climate) and ensure SPD U_c exceeds this by 20% minimum:

SPD U_c ≥ 1.2 × V_oc(coldest)

Example:

V_oc @ -10°C = 580V

Required U_c = 1.2 × 580V = 696V

Select: 1000V U_c SPD (next standard size) ✅

Problema: Installing SPD with >1m total lead length adds significant parasitic inductance, reducing clamping effectiveness by 50-70%.

Typical bad installation:

- SPD mounted on enclosure door

- Ground wire runs across enclosure to grounding bar (1.5m)

- Positive/negative leads also extended (0.5m each)

- Total leads: 2.5m → adds 2500V during fast surges!

Corrección: Mount SPD at busbar junction with all three leads <0.2m each: - Use shortest practical wire routing - Avoid coiled excess wire (creates inductance) - No sharp 90° bends in SPD conductors - Measure and document total lead length <0.5m

Problema: Using single SPD between positive and negative without ground connection provides no protection against common-mode surges.

Why this fails:

- Lightning induces voltage on both poles simultaneously

- Differential SPD only protects against voltage difference between poles

- Common-mode surge (both poles rising together) passes through unprotected

Corrección: Always use three-wire SPD configuration:

- Positive to ground: one MOV

- Negative to ground: one MOV

- Equipment ground connected to building ground electrode

- This protects both common-mode and differential-mode surges

Problema: Installing SPD in hot enclosures without accounting for temperature-induced clamping voltage increase.

Impact:

- Black NEMA enclosure reaches 75°C internal temperature

- SPD clamping voltage increases 15-20% from heat

- 1200V rated U_p becomes 1440V actual

- Voltage margin to inverter withstand reduced dangerously

Corrección: Apply temperature derating factor or improve thermal management:

- Use white/gray enclosures instead of black (-10 to -15°C)

- Add ventilation holes at top/bottom of enclosure

- Mount SPD near top where temperature is highest

- Calculate derated U_p and verify adequate margin remains

Initial Investment:

- Type 2 MOV SPD (20kA, 1200V U_p): $150-250

- Installation labor (1 hour): $100-150

- Total: $250-400 per installation

Two-Stage System:

- String-level SPD: $150-250

- Inverter input SPD: $100-150

- Installation labor (1.5 hours): $150-200

- Total: $400-600 per installation

Protection Value:

- Typical 5kW inverter replacement: $2,000-3,500

- Lost production during replacement: $200-400

- Total risk: $2,200-3,900 per lightning event

Lightning Strike Probability:

- Low-exposure site: 1 strike per 50 years

- Moderate-exposure: 1 strike per 20 years

- High-exposure: 1 strike per 10 years

ROI Calculation (Moderate-Exposure Site):

Expected loss without SPD = $2,500 / 20 years = $125/year

SPD cost = $300 installed

Payback period = $300 / $125 = 2.4 years ✅

Over 25-year system life:

- With SPD: $300 + $0-500 (possible 1 failure) = $800

- Without SPD: 1.25 strikes × $2,500 = $3,125

- Net savings: $2,325 (290% ROI)

Engineering Conclusion: Even in low-exposure areas, SPD protection provides 200-500% ROI over typical 25-year solar system lifespan.

| Parámetro | 600V SPD System | 1000V SPD System |

|---|---|---|

| Maximum String V_oc | 500V (12-15 modules) | 830V (18-22 modules) |

| Typical U_p (Clamping) | 1200-1400V | 2000-2500V |

| Inverter Protection Margin | 300-500V (Better) | 200-300V (Adequate) |

| Device Cost | $150-250 | $200-350 (+30%) |

| MOV Size/Weight | 40-60mm, 200g | 50-80mm, 350g |

| Mejor aplicación | Residential 3-15kW | Commercial 20-100kW |

System Selection Guide:

- Choose 600V SPD: Residential systems <15kw with 12-15 module strings

- Choose 1000V SPD: Commercial systems >20kW with 18-22 module strings

- Never use 600V on 1000V systems: Immediate SPD failure and lost protection

The 600V rating (U_c) represents the maximum continuous DC operating voltage the SPD can withstand without degradation. This is NOT the system voltage—a 600V SPD protects systems with V_oc up to approximately 500V to maintain a 20% safety margin. For residential solar systems with 12-15 modules in series producing 420-540V open-circuit voltage, a 600V U_c SPD provides adequate margin. Always verify your system's V_oc at coldest expected temperature remains below 500V before selecting 600V-class SPD.

Clamping voltage (U_p) determines the maximum voltage that passes through to your inverter during a surge event. Modern 600V-class inverters typically withstand 1500-2000V for brief moments before failure. A 600V SPD with 1200V U_p provides 300-800V protection margin. Lower clamping voltages offer better protection—for example, 1100V U_p vs 1400V U_p means 300V less stress on inverter components. However, excessively low clamping voltages require expensive varistor materials, increasing SPD cost by 2-3×.

MOV-based 600V DC SPDs respond in <25 nanoseconds, making them class i devices per iec 61643-11. this near-instantaneous response protects sensitive inverter semiconductors that can fail in 50-100 nanoseconds when exposed to overvoltage. gas discharge tube (gdt) spds respond slower at but offer higher energy capacity. for residential solar applications, mov technology's fast time is more critical than gdt's rating since induced lightning surges rarely exceed 20-40ka.

SPD lifespan varies dramatically by lightning exposure. Low-exposure sites (plains, valleys) see 20-25 year service life with minimal degradation. High-exposure sites (mountaintops, coastal areas) require replacement every 10-15 years as repeated surge absorption degrades varistor material. Each major lightning event (>10kA) increases clamping voltage by 1-3% through micro-fracturing. After 10-20 high-energy surges, the SPD becomes "worn out" with U_p exceeding specifications by 15-20%. Most quality SPDs include status indicators that turn red/yellow when replacement is needed.

Yes, a single three-wire SPD (positive-to-ground and negative-to-ground) can protect multiple parallel strings connected to the same combiner busbar. The SPD must be rated for the combined maximum current of all strings. For example, six 11A strings require SPD with I_n ≥ 40kA (1.5× × 66A combined). However, using individual SPDs per string provides better fault isolation—if one string develops a ground fault, only that string's SPD is affected rather than losing protection for the entire array.

Installing an underrated SPD causes immediate failure and lost protection. The continuous overvoltage (V_oc exceeding SPD's U_c rating) keeps the MOV in constant conduction, generating heat and rapidly degrading the varistor material. Within days to weeks, the SPD either fails open-circuit (protection lost) or short-circuit (tripping the upstream breaker and shutting down the system). Even if the SPD has sufficient surge current rating (I_n), voltage mismatch makes it completely unsuitable. Always match SPD U_c to system voltage with 20% margin minimum.

Total SPD lead length (positive wire + negative wire + ground wire) should be <0.5m per IEC 61643-11. Each meter of wire adds ~1µH inductance, which contributes 1000-2000V parasitic voltage rise during fast lightning surges. Practical installation: measure straight-line distance from busbar junction to grounding point, multiply by 2.5 (wire routing factor), and verify result is <500mm. If measurement exceeds 500mm, relocate SPD mounting position closer to busbar or use better wire routing to shorten leads.

The 600V DC SPD serves as the primary lightning protection component in 70% of global residential solar installations, making proper specification and installation critical for long-term system reliability.

Key Engineering Takeaways:

1. Clamping voltage must remain <80% of inverter DC withstand rating, accounting for temperature derating and lead inductance additions

2. Response time <25 nanoseconds (mov technology) protects sensitive inverter semiconductors that fail in <100 nanoseconds

3. Lead length <0.5m total is absolutely critical—excessive leads can add 1000-2000V parasitic voltage, defeating the SPD's protection

4. Two-stage protection systems provide 99% reliability vs 85% for single-stage, justifying 40-60% cost premium

5. Proactive replacement after 10-20 major surge events or 15 years in high-exposure sites maintains protection reliability

Understanding the interplay between U_c voltage rating, U_p clamping voltage, response time, and proper installation ensures residential solar systems achieve 25+ year operational life with minimal lightning-related failures.

Related Resources:

- DC SPD Installation Wiring Diagrams for Solar Systems

- 1000V DC SPD Selection for Commercial PV Applications

- Solar Lightning Protection System Design Fundamentals

Ready to specify compliant 600V DC SPD for your installation? Contact SYNODE's lightning protection engineering team for project-specific recommendations including clamping voltage analysis, lead length optimization, and multi-stage coordination calculations for residential 3-20kW solar systems.

Última actualización: February 2026

Autor: Equipo técnico de SYNODE

Revisado por: Lightning Protection Engineering Department

Palabra clave: 600v dc spd

URL Slug: 600v-dc-spd-engineering-clamping-voltage

Meta Título: 600V DC SPD Technical Guide: Clamping Voltage & Response Engineering

Meta Descripción: Complete 600V DC SPD engineering analysis: clamping voltage calculations, response time specifications, MOV vs GDT technology comparison, and IEC 61643-11 compliance for residential solar systems.

Nivel de contenido: Tier 3 (Supporting Content)

Embudo de conversión: Parte superior del embudo (concienciación)

Número de palabras objetivo: 2800-4000 palabras

Objetivo Diagramas de sirena: 3

Por favor, configúrelos en los ajustes de Rank Math, luego borre esta casilla antes de publicar.

The 600V rating (U_c) represents the maximum continuous DC operating voltage the SPD can withstand without degradation. This is NOT the system voltage—a 600V SPD protects systems with V_oc up to approximately 500V to maintain a 20% safety margin. For residential solar systems with 12-15 modules in series producing 420-540V open-circuit voltage, a 600V U_c SPD provides adequate margin. Always verify your system's V_oc at coldest expected temperature remains below 500V before selecting 600V-class SPD.

Clamping voltage (U_p) determines the maximum voltage that passes through to your inverter during a surge event. Modern 600V-class inverters typically withstand 1500-2000V for brief moments before failure. A 600V SPD with 1200V U_p provides 300-800V protection margin. Lower clamping voltages offer better protection—for example, 1100V U_p vs 1400V U_p means 300V less stress on inverter components. However, excessively low clamping voltages require expensive varistor materials, increasing SPD cost by 2-3×.

MOV-based 600V DC SPDs respond in <25 nanoseconds, making them Class I devices per IEC 61643-11. This near-instantaneous response protects sensitive inverter semiconductors that can fail in 50-100 nanoseconds when exposed to overvoltage. Gas discharge tube (GDT) SPDs respond slower at 50-100 nanoseconds but offer higher energy capacity. For residential solar applications, MOV technology's fast response time is more critical than GDT's higher energy rating since induced lightning surges rarely exceed 20-40kA.

SPD lifespan varies dramatically by lightning exposure. Low-exposure sites (plains, valleys) see 20-25 year service life with minimal degradation. High-exposure sites (mountaintops, coastal areas) require replacement every 10-15 years as repeated surge absorption degrades varistor material. Each major lightning event (>10kA) increases clamping voltage by 1-3% through micro-fracturing. After 10-20 high-energy surges, the SPD becomes worn out with U_p exceeding specifications by 15-20%. Most quality SPDs include status indicators that turn red/yellow when replacement is needed.

Yes, a single three-wire SPD (positive-to-ground and negative-to-ground) can protect multiple parallel strings connected to the same combiner busbar. The SPD must be rated for the combined maximum current of all strings. For example, six 11A strings require SPD with I_n ≥ 40kA (1.5× × 66A combined). However, using individual SPDs per string provides better fault isolation—if one string develops a ground fault, only that string's SPD is affected rather than losing protection for the entire array.

Installing an underrated SPD causes immediate failure and lost protection. The continuous overvoltage (V_oc exceeding SPD's U_c rating) keeps the MOV in constant conduction, generating heat and rapidly degrading the varistor material. Within days to weeks, the SPD either fails open-circuit (protection lost) or short-circuit (tripping the upstream breaker and shutting down the system). Even if the SPD has sufficient surge current rating (I_n), voltage mismatch makes it completely unsuitable. Always match SPD U_c to system voltage with 20% margin minimum.

Total SPD lead length (positive wire + negative wire + ground wire) should be <0.5m per IEC 61643-11. Each meter of wire adds ~1µH inductance, which contributes 1000-2000V parasitic voltage rise during fast lightning surges. Practical installation: measure straight-line distance from busbar junction to grounding point, multiply by 2.5 (wire routing factor), and verify result is <500mm. If measurement exceeds 500mm, relocate SPD mounting position closer to busbar or use better wire routing to shorten leads.