Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Understanding PV combiner box selection criteria enables proper component specification matching system requirements to equipment capabilities. This technical specification guide examines string count sizing methodology, current capacity calculations, voltage rating requirements, busbar design specifications, and environmental rating selection. System designers and electrical engineers will find detailed selection matrices, calculation procedures, and compliance verification methods for professional photovoltaic combiner box specifications.

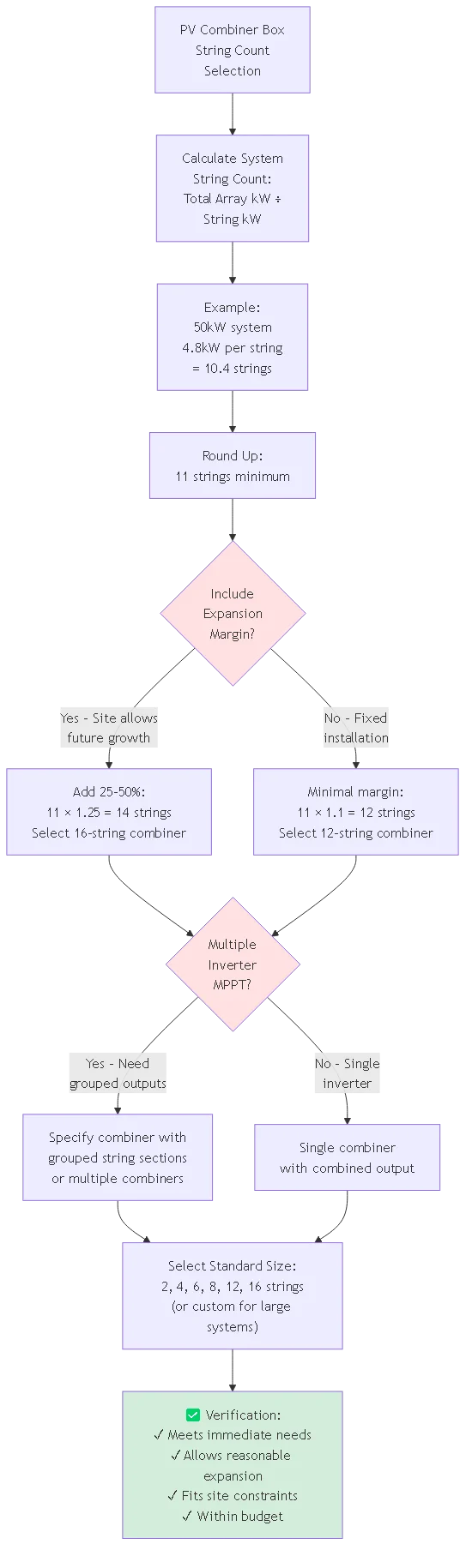

Selecting appropriate combiner box involves balancing multiple technical parameters including string input capacity, combined current handling, voltage withstand capability, environmental protection level, and future expansion allowance. Undersized combiners create bottlenecks limiting system performance while oversized units waste capital budget on unnecessary capacity. Systematic selection methodology ensures optimal combiner specification meeting current requirements with appropriate margin for reliability and potential future expansion.

String input capacity represents primary combiner box specification parameter determining how many individual PV source circuits can terminate at combiner location. Calculate required string count from system design considering array layout, inverter input requirements, and practical installation constraints. Most commercial combiners offer standard configurations: 2-string, 4-string, 6-string, 8-string, 12-string, and 16-string models with custom configurations available for large installations.

String count calculation methodology:

Begin with total array capacity and individual string power output. For 50kW commercial system using 400W modules in 12-module strings (4.8kW per string): required string count = 50kW / 4.8kW ≈ 10.4 strings. Round to next whole number = 11 strings minimum. Select combiner with ≥11 inputs—specify 12-string combiner providing one spare position for future expansion or replacement flexibility.

Account for inverter input channel requirements when multiple inverters parallel-connect at single combiner. Some designs require dedicated string groups per inverter input for maximum power point tracking (MPPT) optimization. For dual-inverter system with independent MPPT channels: specify combiner with grouped outputs or install separate combiners per inverter avoiding cross-connection between MPPT channels.

Future expansion considerations:

Specify 25-50% additional string capacity beyond immediate requirements when physical site allows future array expansion. Rooftop installation with unused roof area or ground-mount with adjacent expansion space benefits from oversized combiner allowing seamless capacity additions without replacing combining equipment. Balance expansion margin against current capital budget constraints—oversizing from 8 to 12 strings costs $400-800 additional but eliminates future replacement expense ($2000-3000 including labor and downtime).

Modular combiner designs allow field-expandable string capacity adding input modules without replacing main enclosure. These systems suit phased installations where total capacity deploys over multiple years. Initial 6-string combiner accepts plug-in expansion modules adding 6 additional inputs reaching 12-string total capacity. Modular approach optimizes cash flow matching equipment investment to revenue-generating capacity deployment.

Each string input requires individual overcurrent protection per NEC 690.9(B) when three or more source circuits parallel at common connection point. This protection prevents backfeed current from healthy strings damaging faulted string during short-circuit or ground-fault conditions. Combiner box string input capacity must accommodate required protection devices—fuses, circuit breakers, or equivalent overcurrent protective devices.

Fuse holder space requirements:

Cylindrical PV fuses (10×38mm gPV type or similar) mount in fuse holders occupying approximately 25-35mm width per string on standard DIN rail. Calculate minimum DIN rail length: (String count × 35mm) + 100mm margin. For 8-string combiner: 8 × 35mm + 100mm = 380mm minimum rail length. Standard combiner enclosures provide 400-500mm rails accommodating 8-12 strings with adequate spacing.

Circuit breaker protection requires more space per string—typical DC circuit breakers occupy 45-55mm DIN rail width for single-pole devices, 90-110mm for two-pole configurations protecting both positive and negative conductors. Eight 2-pole breakers require: 8 × 100mm = 800mm DIN rail length—substantially more than fuse-based protection. Breaker-based combiners use larger enclosures or stacked rail configurations accommodating space requirements.

Terminal block capacity:

String input terminals must handle individual string current (typically 10-15A for current module technology) with adequate derating for elevated ambient temperature inside combiner enclosure. Specify terminals rated ≥125% of string short-circuit current per NEC 690.8(B)(1): For 12A Isc strings, minimum terminal rating = 12A × 1.25 = 15A. Apply temperature derating if combiner internal temperature exceeds conductor insulation rating temperature (75°C or 90°C typical).

Quality combiners provide clearly labeled terminal positions identifying each string input with corresponding fuse or breaker location. Numbering schemes (String 1, String 2, etc.) or alphanumeric codes (A1, A2, B1, B2 for grouped configurations) simplify installation and troubleshooting. Avoid combiners with generic unmarked terminals creating confusion during commissioning and maintenance.

| String Count | Typical System Size | Enclosure Size | DIN Rail Length | Typical Cost Range |

|---|---|---|---|---|

| 2-string | 5-10kW residential | 300×250×150mm | 200mm | $200-400 |

| 4-string | 10-20kW residential | 400×300×200mm | 300mm | $300-600 |

| 6-8 string | 25-50kW commercial | 500×400×250mm | 400-500mm | $500-1200 |

| 12-16 string | 75-150kW commercial | 700×500×300mm | 800-1000mm dual rail | $1200-2500 |

💡 Key Insight: String count specification should account for both immediate system requirements and realistic future expansion scenarios. However, avoid excessive over-specification—unused inputs increase combiner cost, enclosure size, and installation complexity without providing value. Target 10-25% spare capacity striking balance between flexibility and cost optimization.

Combiner box output current capacity must handle sum of all connected string short-circuit currents with NEC-mandated safety factors. Output busbars, terminals, and conductors rate for continuous operation at maximum combined current without exceeding temperature limits. Undersized output capacity creates voltage drop, excessive heating, and potential fire hazard during normal operation.

Calculate required output current capacity:

1. Determine string short-circuit current: From module datasheet Isc specification (typically 11-13A for 400-500W modules)

2. Calculate combined current: Total Isc = String count × Individual string Isc

3. Apply NEC 690.8(B) continuous factor: Design current = Total Isc × 1.25

4. Apply NEC 690.8(B)(1) additional factor: Output conductor/busbar = Design current × 1.25 (or 1.56× Isc total)

5. Temperature derating: Apply NEC 310.15(B)(2)(a) correction if ambient >30°C

6. Select combiner rating: Choose next standard rating ≥ calculated requirement

Example calculation for 8-string combiner:

– String Isc: 12A per string

– Combined Isc: 8 × 12A = 96A

– NEC 690.8(B): 96A × 1.25 = 120A design current

– NEC 690.8(B)(1): 120A × 1.25 = 150A output capacity required

– Standard rating selection: 150A or 200A combiner (200A provides margin)

Some manufacturers specify combiner ratings using “string capacity” (e.g., “8-string, 15A per string”) while others specify absolute output current (“125A output capacity”). Verify rating methodology ensuring compliance with NEC continuous current requirements. String-rated combiners assume standard string current; verify compatibility when using high-output modules exceeding assumed current levels.

Output busbar cross-sectional area determines current carrying capacity and voltage drop under load. Copper busbar typical for quality combiners provides excellent conductivity and thermal performance. Calculate minimum busbar cross-section from: Area = I / J, where I is design current and J is allowable current density (typically 1.5-2.0 A/mm² for copper depending on cooling method).

For 150A design current combiner:

– At J = 1.5 A/mm²: Area = 150A / 1.5 = 100mm²

– Typical dimensions: 5mm thick × 20mm wide = 100mm²

– This matches calculated requirement providing adequate capacity

Busbar material quality affects performance and longevity. Electrolytic tough pitch (ETP) copper (99.9% purity) provides optimal conductivity but costs more than brass or copper-plated aluminum alternatives. Premium combiners use tinned copper busbar preventing oxidation and maintaining low contact resistance over decades. Avoid combiners using aluminum busbar unless specifically designed with appropriate anti-corrosion treatment and increased cross-section compensating for aluminum’s lower conductivity (approximately 60% of copper).

Output terminal specifications:

Output terminals connecting combiner to inverter feeder conductors must accommodate large-gauge wire typical for high-current DC circuits. Common output conductor sizes range from 6 AWG (55A capacity) to 4/0 AWG (260A capacity) depending on combined current and conductor run length. Specify combiner with terminal blocks accepting anticipated conductor size without requiring expensive custom terminals or adapters.

Compression-style terminals provide superior long-term reliability for high-current connections compared to screw-clamp terminals. Compression terminals use mechanical crimping creating gas-tight connection preventing oxidation and maintaining stable contact resistance. Torque specifications for output terminals typically range 8-12 N⋅m (70-106 lb⋅in) for M6 hardware, 15-20 N⋅m (133-177 lb⋅in) for M8 hardware used on larger combiners.

Internal voltage drop through combiner busbar and connections affects system efficiency. Calculate total voltage drop from: Vdrop = I × R, where I is combined current and R is total internal resistance. Quality combiners specify internal resistance <1mΩ producing minimal voltage drop at rated current.

For 120A operating current through 1mΩ combiner: Vdrop = 120A × 0.001Ω = 0.12V drop. At 600V system voltage: efficiency loss = 0.12V / 600V = 0.02% (negligible). However, poor-quality combiners with loose connections, undersized busbars, or corroded surfaces may exhibit 5-10mΩ resistance creating 0.6-1.2V drop (0.1-0.2% loss). While individually small, cumulative losses from combiner plus conductor voltage drops compound affecting system energy production over 25-year lifetime.

Specify combiners with documented internal resistance specifications rather than generic datasheets lacking electrical performance data. Request manufacturer test reports measuring voltage drop across combiner at various current levels verifying published specifications.

Combiner box voltage rating must exceed maximum system open-circuit voltage including temperature compensation per NEC 690.7. Photovoltaic module voltage increases significantly at low temperatures potentially exceeding nominal system voltage by 15-20%. Specify combiner voltage class with adequate margin above worst-case calculated maximum voltage ensuring safe operation under all conditions.

Standard DC voltage classes:

600V class combiners: Suitable for systems with temperature-compensated Voc ≤600V. Typical string configuration: 10-12 modules using 48-52V Voc panels. Common in residential and small commercial installations. Equipment rated per UL standard voltage levels providing tested safety margin.

1000V class combiners: Accommodate systems with Voc ≤1000V. Typical configuration: 18-20 modules per string enabling longer strings reducing conductor count and installation labor. Dominant voltage class for commercial installations (50-500kW). Requires enhanced insulation coordination and clearance distances per IEC 60664-1.

1500V class combiners: Utility-scale systems with Voc ≤1500V. Configuration: 28-32 modules per string maximizing string length for multi-megawatt installations. Specialized equipment meeting stringent high-voltage safety requirements. Limited manufacturer availability compared to 600V/1000V classes.

Voltage class selection procedure:

1. Calculate string Voc at standard test conditions (STC) from datasheet

2. Determine coldest expected ambient temperature at site location

3. Find module temperature coefficient for Voc (typically −0.28 to −0.35%/°C)

4. Calculate cold temperature Voc: Voc(cold) = Voc(STC) × [1 + β × (T_cold − 25°C)]

5. Add 10% safety margin accounting for measurement uncertainty and transients

6. Select next standard voltage class above calculated maximum

Example: 12-module string, 50V Voc modules, −30°C minimum temperature:

– String Voc(STC): 12 × 50V = 600V

– Temperature factor: 1 + (−0.003)(−30 − 25) = 1 + 0.165 = 1.165

– Cold Voc: 600V × 1.165 = 699V

– With 10% margin: 699V × 1.10 = 769V

– Required class: Specify 1000V combiner (600V class inadequate)

Voltage class determines required insulation levels and clearance distances preventing flashover and maintaining personnel safety. Higher voltage classes demand increased spacing between energized parts, enhanced insulation materials, and specific construction techniques meeting electrical codes.

IEC 60664-1 clearance requirements:

For 1000V equipment in Pollution Degree 2 environment (typical solar installation):

– Minimum clearance (air gap): 14mm basic insulation

– Minimum creepage (surface path): 20mm basic insulation

– Working voltage: System maximum DC voltage

Quality combiners exceed minimum requirements providing margin for transient overvoltages and long-term reliability. Premium designs specify 150-200% of minimum clearances ensuring robust performance in harsh outdoor environments with dust, moisture, and temperature extremes.

Insulation coordination between SPD voltage protection level and combiner insulation rating prevents damage during surge events. Combiner insulation withstand must exceed SPD clamping voltage plus margin: If SPD VPL = 3000V, combiner should withstand ≥4000V impulse ensuring surge protection doesn’t stress combiner insulation approaching failure threshold.

Combiner box enclosure environmental rating determines suitability for installation location considering weather exposure, temperature extremes, dust/moisture ingress, and mechanical hazards. Selecting appropriate rating ensures reliable long-term operation without premature failure from environmental damage.

NEMA ratings for combiner box applications:

NEMA 1 (Indoor, general purpose): Protects against incidental contact with enclosed equipment and falling dirt. Suitable only for climate-controlled inverter rooms or electrical equipment buildings. Lowest cost but no weather protection. Not suitable for rooftop or outdoor installations.

NEMA 3R (Outdoor, rain resistant): Most common rating for rooftop and outdoor combiner installations. Protects against falling rain, sleet, snow, and external ice formation. Ventilated design allows internal cooling but not sealed against wind-driven dust or pressurized water. Adequate for most commercial rooftop applications.

NEMA 4 (Outdoor, watertight): Sealed enclosure protecting against wind-driven rain, splashing water, hose-directed water, and external ice formation. Required for ground-mount utility-scale systems, harsh coastal environments, or wash-down areas requiring periodic cleaning. Costs 30-40% more than NEMA 3R but provides comprehensive environmental protection.

NEMA 4X (Outdoor, corrosion-resistant): Provides NEMA 4 protection plus corrosion resistance using stainless steel or powder-coated aluminum construction. Essential for coastal installations, industrial environments with chemical exposure, or locations with severe corrosion potential (saltwater, industrial pollutants). Premium pricing (60-80% above NEMA 3R) justified by decades longer service life preventing premature replacement.

IP rating equivalents:

International Protection (IP) rating system provides alternative environmental classification common in global markets. First digit indicates solid ingress protection (dust), second digit indicates liquid ingress protection (water).

– IP54: Equivalent to NEMA 3R—dust protected, splash resistant

– IP65: Equivalent to NEMA 4—dust tight, water jet protected

– IP66: Enhanced NEMA 4—dust tight, powerful water jet protected

Some specifications require both NEMA and IP ratings ensuring compliance with North American and international standards. Quality manufacturers test to both standards documenting compliance through third-party certification.

Operating temperature range indicates environmental extremes combiner withstands maintaining rated performance. Standard combiners specify −25°C to +55°C range adequate for most temperate climates. Extreme climate installations require expanded ranges:

Cold climate requirements (northern latitudes, high altitude):

– Extended low temperature: −40°C to +55°C

– Cold-rated internal components (terminals, SPDs, monitoring electronics)

– Enclosure materials maintaining flexibility at low temperature (avoid brittle plastics)

Hot climate requirements (desert, tropical, equatorial):

– Extended high temperature: −25°C to +70°C

– Adequate ventilation preventing excessive internal temperature rise

– High-temperature-rated components and insulation

– Thermal management for monitoring electronics

Internal temperature inside combiner enclosure typically exceeds ambient by 10-20°C due to heat generation from resistive losses, SPD leakage current, and solar radiation heating metal enclosures. This temperature rise affects component derating requiring analysis ensuring all internal components operate within ratings at maximum expected internal temperature.

| Installation Location | Recommended NEMA Rating | Temperature Range | Special Considerations |

|---|---|---|---|

| Rooftop (Standard) | NEMA 3R or IP54 | −25°C to +55°C | UV-resistant, rain protection |

| Coastal Environment | NEMA 4X or IP66 | −25°C to +55°C | Stainless steel, salt fog rated |

| Desert Ground-Mount | NEMA 4 or IP65 | −25°C to +70°C | High temp rating, dust sealing |

| Cold Climate | NEMA 3R/4 or IP54/65 | −40°C to +55°C | Cold-rated components, flexible gaskets |

| Indoor Equipment Room | NEMA 1 or IP20 | −10°C to +40°C | Climate controlled, minimal exposure |

⚠️ Important: Environmental rating represents minimum protection level—actual installation exposure may demand higher rating than minimum specification suggests. Coastal installations 5-10km inland still experience salt-laden wind requiring corrosion-resistant materials despite being classified “non-coastal.” Consult with local installers familiar with regional environmental challenges ensuring adequate protection specification.

Many combiner boxes integrate surge protective devices (SPDs) providing centralized transient overvoltage protection for consolidated string outputs. Integrated SPD installation simplifies system design, reduces installation labor versus separate SPD enclosure, and ensures proper SPD coordination with string protection devices. Specify integrated SPD when combiner location suits surge protection requirements per NEC 690.35.

SPD integration specifications:

Select SPD Type 1 or Type 2 based on combiner installation location and lightning exposure assessment. Combiners at array origin potentially exposed to direct strike energy require Type 1 SPD (Iimp rated, 10/350μs waveform). Combiners in protected building locations coordinate with upstream Type 1 protection using Type 2 SPD (In rated, 8/20μs waveform).

SPD voltage rating (MCOV) must exceed system maximum voltage with margin: MCOV ≥ 1.25 × Voc(cold). For 1000V system with 1200V cold temperature Voc: required MCOV = 1200V × 1.25 = 1500V minimum. Specify 1500V or 1800V MCOV SPD providing adequate margin.

SPD current rating selection depends on expected surge exposure. Moderate-exposure locations: Type 2 with In = 20kA adequate. High-exposure locations (rural, mountaintop, coastal): Type 2 with In = 30-40kA or Type 1 with Iimp = 25-50kA extends service life reducing replacement frequency.

Advanced combiners integrate string-level current monitoring providing real-time visibility into individual string performance. String monitors detect underperforming strings indicating module damage, soiling, partial shading, or wiring problems enabling targeted maintenance rather than troubleshooting entire array. Monitoring justification depends on system size and O&M budget.

Monitoring specifications:

Current sensor technology: Hall-effect sensors or current transformers measure DC current from each string with typical accuracy ±1-2%. Hall-effect sensors provide non-intrusive measurement clamping around conductor without circuit interruption. Current transformers require conductor pass-through but cost less for equivalent accuracy.

Communication protocol: Modbus RTU (RS-485) represents industry-standard protocol connecting combiner monitors to supervisory control and data acquisition (SCADA) systems or cloud monitoring platforms. Some premium systems offer Ethernet, wireless (cellular, WiFi), or proprietary protocols. Verify protocol compatibility with existing monitoring infrastructure before specifying.

Data logging: Onboard memory stores historical current measurements supporting performance analysis and warranty claims. Minimum 30-day data retention recommended; premium systems provide years of historical data. Time-synchronized logging correlates combiner performance with weather data and inverter output identifying system-level patterns.

Alarm thresholds: Configurable current deviation alarms alert operators when individual string output falls below expected value (typically 80-90% of average string current). Rapid alarm response minimizes energy loss from undetected failures.

Some combiner designs integrate DC disconnect switch providing load-break isolation capability per NEC 690.15 requirements. Integrated disconnect eliminates separate disconnect enclosure simplifying installation and reducing equipment count. However, disconnect integration adds cost ($300-800 depending on current rating) and complexity potentially outweighing convenience benefits for smaller systems.

Disconnect specifications:

Load-break rating: Disconnect must interrupt full-load DC current at system voltage without creating sustained arc. Specify load-break rated switches meeting UL 98 or IEC 60947-3 standards—isolation-only switches lacking load-break capability violate code for this application.

Current rating: Match or exceed combiner output current capacity. For 150A combiner, specify ≥150A disconnect providing margin for transient currents and temperature derating.

Visible break indication: Disconnect mechanism must provide clear visual indication of open/closed status per NEC 690.13(G). Padlockable handle in OFF position prevents unauthorized energization during maintenance.

Ground fault protection integration: Some disconnects integrate ground fault detection and interruption per NEC 690.41 requirements. Integrated GFP simplifies compliance for systems requiring ground fault protection but adds significant cost ($500-1500 depending on rating).

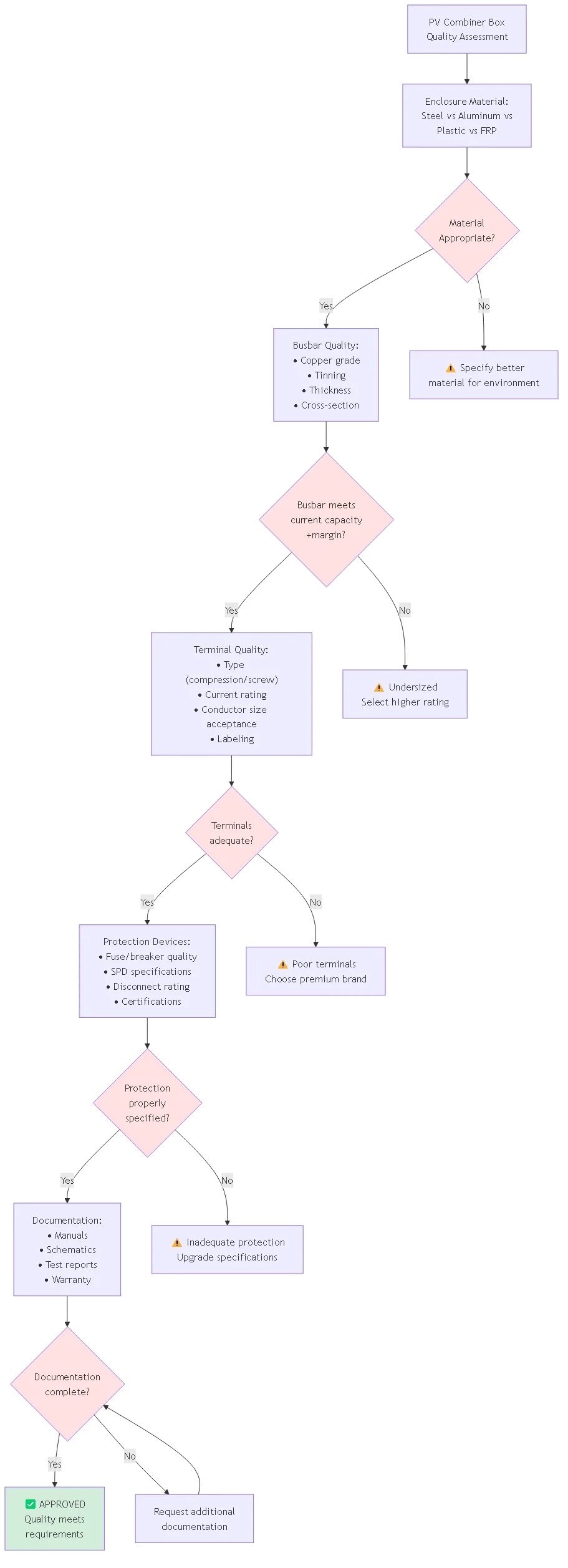

Enclosure material affects environmental durability, thermal performance, weight, and cost. Standard options include steel, aluminum, polycarbonate plastic, and fiberglass-reinforced polyester. Material selection balances application requirements against budget constraints.

Steel enclosures:

– Advantages: High strength, good EMI shielding, lowest cost for large enclosures

– Disadvantages: Heavy (limiting rooftop applications), requires corrosion protection (powder coating or galvanizing)

– Applications: Ground-mount installations, utility-scale systems, budget-constrained projects

– Cost: Base pricing ($500-1000 for 8-string combiner)

Aluminum enclosures:

– Advantages: Natural corrosion resistance, excellent heat dissipation, 1/3 weight of steel

– Disadvantages: Higher cost than steel, lower strength (thicker walls required)

– Applications: Rooftop installations (weight-sensitive), coastal environments

– Cost: Premium pricing (+30-50% vs steel)

Polycarbonate plastic:

– Advantages: Excellent corrosion resistance, transparent options allowing interior inspection, lightweight

– Disadvantages: Limited size (structural strength constraints), UV degradation without stabilizers

– Applications: Small residential combiners (2-4 string), indoor installations

– Cost: Moderate pricing (comparable to steel for small sizes)

Fiberglass-reinforced polyester (FRP):

– Advantages: Outstanding corrosion resistance, good strength-to-weight ratio, UV stable

– Disadvantages: Higher cost, limited manufacturer availability

– Applications: Severe corrosion environments (chemical plants, offshore), ultra-long service life requirements

– Cost: Premium pricing (+50-80% vs steel)

Internal component quality determines combiner long-term reliability and maintenance requirements. Quality indicators separate premium combiners from budget alternatives.

Busbar quality:

– Premium: Electrolytic tough pitch (ETP) copper, tinned surfaces, minimum 5mm thickness

– Standard: Commercial copper, untinned, 3-4mm thickness

– Budget: Brass or copper-plated aluminum, 2-3mm thickness

Terminal blocks:

– Premium: Compression-style, rated 125% of application current, clearly labeled, captive hardware

– Standard: Screw-clamp, rated 100% of application current, numbered positions

– Budget: Generic terminal strips, minimal labeling, hardware that detaches during service

Wiring and internal routing:

– Premium: Pre-wired internal connections, cable management, color-coded conductors, torque markings

– Standard: Terminal-to-terminal jumpers, basic routing, standard color codes

– Budget: Minimal internal wiring, unclear routing, inconsistent terminations

Documentation and labeling:

– Premium: Comprehensive manual, single-line diagram inside enclosure door, detailed component labels, QR codes for online resources

– Standard: Basic manual, schematic provided separately, component identification labels

– Budget: Minimal documentation, generic labeling, limited support resources

Request manufacturer quality documentation including:

– Material certificates (copper purity, enclosure material specifications)

– Component datasheets (terminals, fuses, SPDs, monitoring equipment)

– Third-party test reports (temperature rise, short-circuit testing, environmental testing)

– Warranty terms (typically 2-5 years for standard, 5-10 years for premium)

Determine combiner box size from three primary parameters: string count, combined current capacity, and voltage rating. Calculate required string count from total array capacity divided by individual string power: For 75kW system with 5kW strings = 15 strings minimum. Add 10-25% expansion margin: specify 16-18 string combiner. Calculate combined current from string Isc multiplied by NEC 690.8(B)(1) factor 1.56: For 15 strings at 11A each = 165A × 1.56 = 257A capacity required—select 300A rated combiner.

Voltage rating must exceed temperature-compensated maximum Voc with margin. Calculate string cold temperature Voc then add 10% safety factor: If calculated maximum = 720V, specify 1000V class combiner (600V inadequate). Consider environmental rating based on installation location: NEMA 3R for standard rooftop, NEMA 4/4X for harsh outdoor or coastal environments. Request manufacturer sizing assistance providing system parameters ensuring optimal specification.

Primary differences between 2-string and 4-string combiners include physical size, current handling capacity, and price. Two-string combiners occupy compact enclosures (typically 300×250mm) suitable for residential installations with limited roof space. Four-string units use larger enclosures (400×300mm) accommodating additional string inputs, higher current-rated busbars and terminals, and potentially integrated features (monitoring, SPDs, disconnect) impractical in smaller 2-string packages.

Current capacity scales proportionally: 2-string combiner rated 25-30A output handles two 12A strings. Four-string version rated 50-60A output accommodates four strings. However, pricing doesn’t scale linearly—4-string combiner costs 40-60% more than 2-string (not 2×) due to shared enclosure, mounting hardware, and manufacturing efficiency. For installations requiring four strings, single 4-string combiner costs less and installs faster than two separate 2-string units.

String count selection should account for realistic expansion scenarios. Specify 4-string combiner even for initial 2-3 string installation when future array expansion likely within 3-5 years. Incremental cost ($100-200) avoids future combiner replacement expense ($800-1200 including labor and system downtime) if array capacity increases.

Using automotive fuse blocks instead of purpose-built PV combiners creates numerous code compliance and safety issues. Automotive fuse blocks typically rate only 12-48V DC lacking voltage rating for photovoltaic systems (600-1500V typical). Insulation, clearances, and creepage distances in automotive products inadequate for PV voltages creating flashover and shock hazards. NEC 690.4(D) requires PV equipment “identified for application” meaning listed and labeled for photovoltaic use—automotive components lack required listings.

Automotive fuses use different breaking capacity ratings than PV-rated gPV fuses. Standard automotive fuses may not safely interrupt DC fault current at PV voltages potentially creating arc flash or fire hazard. Automotive fuse blocks also lack proper string-to-output busbar coordination, adequate environmental protection (typically indoor-rated), and cable management for multiple high-voltage DC conductors.

Purpose-built PV combiner boxes include factory integration of properly rated components, third-party safety testing (UL, TÜV, IEC certifications), and engineering documentation proving code compliance. While initial cost higher ($300-800 vs $30-80 for automotive fuse blocks), compliant PV combiners avoid inspection rejection, insurance coverage issues, and potential liability from using improperly rated equipment. The modest investment ensures safe, reliable, code-compliant installation.

Essential certifications for professional PV combiner installations include UL 1741 (inverters, converters, controllers and interconnection system equipment), UL 508A (industrial control panels), or equivalent IEC certifications (IEC 62109, IEC 61439). These listings verify combiner construction meets safety standards including proper wire sizing, adequate clearances, appropriate overcurrent protection, and environmental rating verification. Certification labels on combiner nameplate allow electrical inspector to verify compliance during plan review and field inspection.

Regional requirements add additional certifications: CE marking for European installations, CCC certification for China, PSE mark for Japan. Some jurisdictions require IEEE 1547 compliance for systems interconnecting with utility grid. Request manufacturer documentation package including certificates of conformity, test reports from accredited laboratories (UL, TÜV, Intertek, CSA), and Declaration of Conformity per applicable regional standards.

Component-level certifications also matter: PV fuses should meet UL 2579 or IEC 60269-6 standards, DC circuit breakers require UL 489 DC rating or IEC 60947-2, SPDs need UL 1449 and IEC 61643-31 listings. Integrated monitoring equipment may require additional certifications (UL 61010, IEC 61010 for measuring equipment). Verify all internal components carry appropriate certifications—generic components lacking proper ratings create code violations even if combiner enclosure itself carries listing.

Quality PV combiner boxes provide 20-25 year service life matching photovoltaic system operational lifetime when properly specified for application environment. Combiner enclosure and passive components (busbars, terminals, wire) exhibit minimal degradation under normal operating conditions. Active components (fuses, circuit breakers, SPDs, monitoring electronics) require periodic inspection and replacement throughout system lifetime.

String fuses typically survive system life unless subjected to fault conditions requiring replacement. However, proactive fuse replacement every 10-15 years provides insurance against age-related degradation. Circuit breakers require testing every 3-5 years verifying proper trip characteristics—replace breakers showing degraded performance. Surge protective devices degrade with each surge event—typical SPD lifespan 5-10 years depending on lightning exposure requiring scheduled replacement based on manufacturer specifications or surge event counting.

Environmental exposure affects combiner longevity. Coastal installations experience accelerated corrosion requiring 5-10 year combiner replacement unless specified with corrosion-resistant materials (stainless steel, NEMA 4X). Desert environments with extreme temperature cycling and abrasive dust reduce service life to 15-20 years typical. Climate-controlled indoor installations easily achieve 25-30 year service life with minimal maintenance.

Premium combiner investments ($1500-3000 vs $500-800 for budget alternatives) justify through extended service life, reduced maintenance requirements, and included warranties (5-10 years premium vs 1-2 years budget). Calculate total cost of ownership including replacement labor and system downtime—premium combiners often cost less over 25-year system lifetime despite higher initial investment.

String monitoring justification depends on system size, lightning exposure, O&M budget, and performance guarantee requirements. Systems >100kW with dedicated O&M resources benefit from string monitoring enabling rapid fault detection and targeted maintenance. Residential systems <20kW rarely justify monitoring cost ($400-800 per combiner) given limited O&M budget and straightforward troubleshooting for small string counts.

String monitoring proves valuable for installations experiencing frequent faults (multiple lightning events per year, persistent soiling, shading issues) where rapid fault detection minimizes energy losses. Calculate break-even point comparing monitoring cost against expected energy loss from undetected faults. If monitoring prevents 500kWh annual loss (worth $50-100 depending on electricity rate) over 10-year period, total value = $500-1000 justifying $600 monitoring investment through energy savings alone.

Performance guarantee scenarios often mandate string monitoring. Power purchase agreements with availability guarantees penalize undetected failures leading to production shortfalls. String monitoring satisfies due diligence requirements proving operator detected and resolved faults promptly rather than allowing extended downtime. Insurance companies may offer reduced premiums for monitored systems recognizing improved risk management and faster claim response.

For systems without clear monitoring justification, specify combiner with monitoring-ready infrastructure (current sensor conduit stubs, communication wire provision, mounting space for future modules) allowing cost-effective monitoring retrofit if operational experience reveals unexpected fault frequency or O&M resources expand enabling active monitoring programs.

Quality PV combiner prices range from $300-3500 depending on string count, current rating, voltage class, environmental rating, and integrated features. Residential 2-4 string combiners cost $300-800 for basic configurations (fuses, busbar, terminals in NEMA 3R enclosure). Commercial 6-12 string units cost $800-1800 for standard specifications, $1500-2500 for premium materials or integrated features (monitoring, SPDs, disconnect).

Utility-scale 16+ string combiners with advanced features cost $2000-3500 per unit including string monitoring, integrated Type 1 SPDs, disconnect switches, and communication interfaces. Custom combiners for specialized applications (extra-high current, unusual voltage classes, extreme environmental ratings) cost $3000-6000 depending on requirements.

Budget alternatives ($200-500) exist but often lack proper certifications, use inferior materials, or omit critical features creating long-term reliability and code compliance issues. These budget units may appear adequate for simple applications but frequently require expensive replacement within 5-10 years. Premium pricing ($1500-3000+) buys enhanced materials (stainless steel, premium copper), comprehensive certifications, better warranties (5-10 years), and technical support reducing total cost of ownership over system lifetime.

Installation labor typically adds $300-800 depending on location accessibility, conductor routing complexity, and code jurisdiction inspection requirements. Total installed cost including combiner equipment and labor typically represents 2-5% of total PV system capital cost—modest investment providing essential consolidation and protection functions supporting reliable long-term system operation.

Professional PV combiner box selection requires systematic analysis of string count requirements, current capacity specifications, voltage class determination, environmental rating selection, and quality assessment. Understanding these selection parameters enables optimal combiner specification matching system needs to equipment capabilities while providing appropriate margin for reliability and potential future expansion.

Key Takeaways:

1. String count specification should accommodate immediate requirements plus 10-25% expansion margin balancing flexibility against cost

2. Current capacity calculation follows NEC 690.8(B)(1) requiring 1.56× combined string Isc for continuous rating

3. Voltage class selection based on temperature-compensated maximum Voc plus 10% safety margin selecting standard class (600V, 1000V, 1500V)

4. Environmental rating matches installation exposure with NEMA 3R adequate for standard rooftop, NEMA 4/4X for harsh outdoor or coastal

5. Quality indicators including busbar construction, terminal specifications, component certifications, and documentation completeness separate premium from budget alternatives

Proper combiner selection directly affects system reliability, code compliance, installation cost, and long-term maintenance requirements. Investment in appropriately sized, properly specified, and professionally certified combiner boxes pays dividends through reliable operation, simplified troubleshooting, and reduced conductor installation costs over 25-year photovoltaic system lifetime.

Related Resources:

– What is a Combiner Box? PV System Components Explained

– PV Combiner Box Wiring: NEC 690.15 Installation Standards

– DC SPD Integration: Surge Protection for Combiner Boxes

Ready to specify optimal combiner boxes for your solar projects? Contact our photovoltaic system engineering team for application-specific combiner sizing, component selection, and certification verification ensuring code-compliant, cost-effective installations meeting your performance requirements.

Last Updated: December 2025

Author: SYNODE Technical Team

Reviewed by: PV System Design Engineering Department

Focus Keyword: – **Primary Focus Keyword**: `pv combiner boxes`

URL Slug:

Meta Title: PV Combiner Box Selection: String Count & Current Capacity 2025

Meta Description: Technical PV combiner box selection guide: string count sizing, current capacity calculations, voltage rating requirements, busbar specifications, enclosure selection, and NEC 690.15 compliance for solar installations.

Content Tier: Tier 3 (Supporting Content)

Conversion Funnel: Top of Funnel (Awareness)

Target Word Count: 2800-4000 words

Target Mermaid Diagrams: 3

Please configure these in Rank Math settings, then delete this box before publishing.

Determine size from three parameters: string count (array capacity ÷ string power + 10-25% margin), combined current (string Isc × 1.56 per NEC 690.8), and voltage rating (temperature-compensated Voc + 10% margin). For 75kW system with 5kW strings = 15 strings, specify 16-18 string combiner. Calculate current: 15 × 11A × 1.56 = 257A, select 300A combiner. Voltage: if calculated max = 720V, specify 1000V class. Consider environmental rating: NEMA 3R for rooftop, NEMA 4/4X for harsh environments.

Primary differences include size, current capacity, and price. Two-string combiners use compact 300×250mm enclosures suitable for residential installations, rated 25-30A output. Four-string units use 400×300mm enclosures, rated 50-60A output, accommodating additional features. Pricing doesn’t scale linearly—4-string costs 40-60% more than 2-string (not 2×) due to manufacturing efficiency. For four-string installations, single 4-string combiner costs less and installs faster than two 2-string units.

No—automotive fuse blocks create code compliance and safety issues. They typically rate only 12-48V DC lacking voltage rating for PV systems (600-1500V). Insulation and clearances inadequate for PV voltages. NEC 690.4(D) requires PV equipment identified for application—automotive components lack required UL or IEC listings. Automotive fuses use different breaking capacity than PV gPV fuses and may not safely interrupt DC fault current. Purpose-built PV combiners include proper ratings, certifications, and documentation ensuring safe code-compliant installations.

Essential certifications include UL 1741, UL 508A, or equivalent IEC certifications (IEC 62109, IEC 61439). These verify construction meets safety standards including proper sizing, clearances, overcurrent protection, and environmental ratings. Regional requirements add CE (Europe), CCC (China), PSE (Japan). Component certifications matter: PV fuses need UL 2579 or IEC 60269-6, DC breakers require UL 489 or IEC 60947-2, SPDs need UL 1449 and IEC 61643-31. Request manufacturer documentation including test reports from accredited laboratories.

Quality combiners provide 20-25 year service life matching PV system lifetime when properly specified. Enclosure and passive components (busbars, terminals) exhibit minimal degradation. Active components require periodic replacement: fuses last system life unless faulted, SPDs degrade 5-10 years depending on exposure. Environmental exposure affects longevity—coastal installations require corrosion-resistant materials for full service life. Premium investments ($1500-3000) justify through extended life, reduced maintenance, and 5-10 year warranties versus 1-2 years for budget alternatives.

Monitoring justification depends on system size, O&M budget, and performance requirements. Systems >100kW benefit from string monitoring enabling rapid fault detection. Residential <20kW rarely justify $400-800 monitoring cost. Calculate break-even: if monitoring prevents 500kWh annual loss worth $50-100 over 10 years (total $500-1000), it justifies $600 investment. Performance guarantees often mandate monitoring for due diligence. Without clear justification, specify monitoring-ready infrastructure allowing cost-effective future retrofit if operational experience reveals need.

Quality combiners range $300-3500 depending on specifications. Residential 2-4 string: $300-800 basic, $500-1200 with features. Commercial 6-12 string: $800-1800 standard, $1500-2500 premium. Utility-scale 16+ string with monitoring, SPDs, disconnect: $2000-3500. Custom specifications: $3000-6000. Budget alternatives ($200-500) often lack certifications and use inferior materials requiring replacement within 5-10 years. Installation labor adds $300-800. Total installed cost represents 2-5% of PV system capital—modest investment for essential functionality.